13

Alpha 240XP and 240XE - Installation

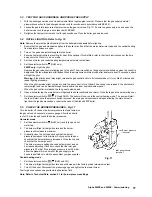

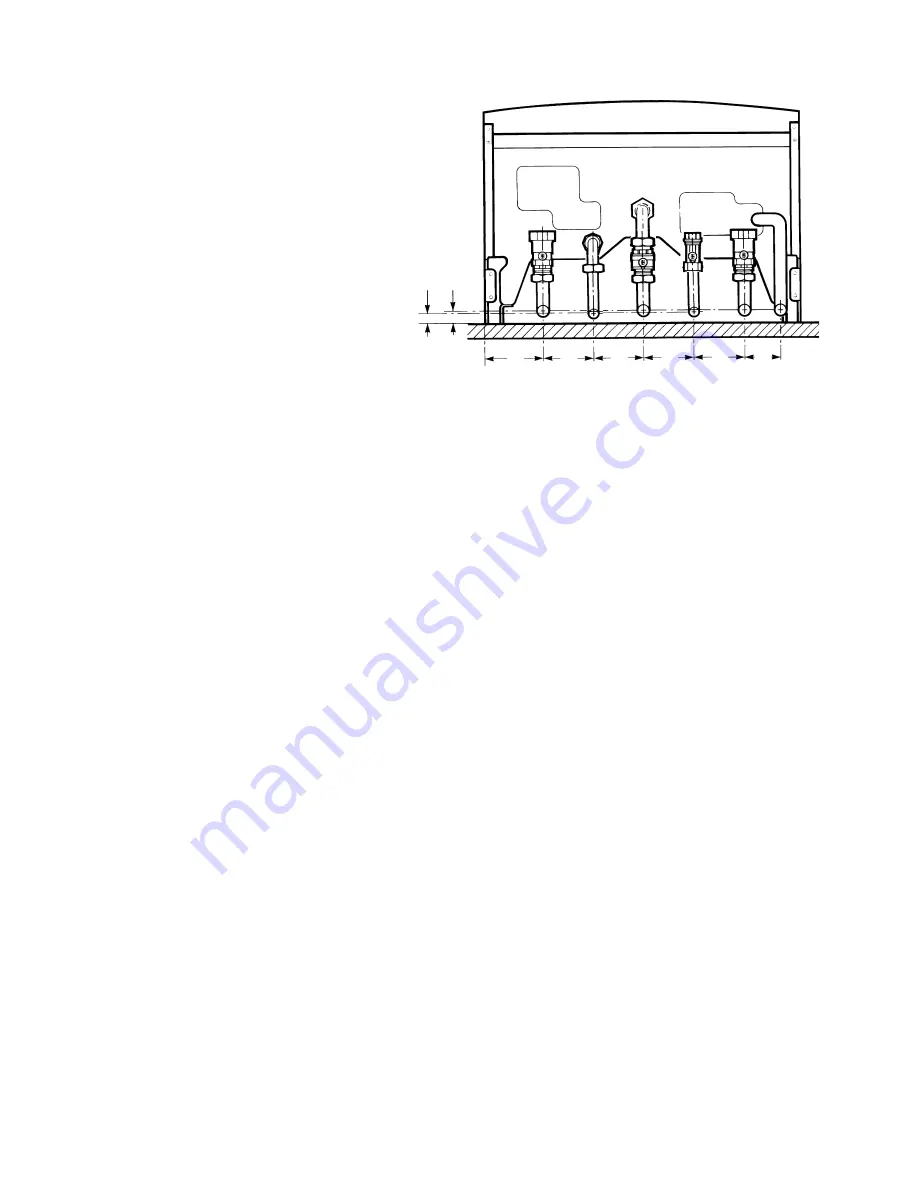

Fig. 11

A - Heating flow (22 mm)

B - Hot water outlet (15 mm)

C - Gas inlet (22 mm)

D - Cold water mains inlet (15 mm)

E - Heating return (22 mm)

F - Pressure relief valve (15 mm)

Note: Both Heating return and Cold water

mains inlet valves contain serviceable filters.

4.6

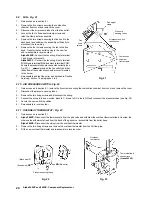

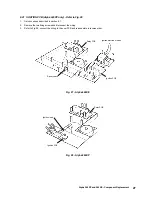

FIT THE FLUE - Figs. 12, 13

1.

The following procedure applies to both rear or side exit flue. The only difference being the lengths to which the ducts are cut.

Rear flue Outer air duct length = finished wall thi 110 mm.

Inner flue duct length = finished wall thi 147 mm.

Side flue

Outer air duct length = finished wall thi the distance from the inside wall to the side of the 145 mm.

Inner flue duct length = finished wall thi the distance from the inside wall to the side of the 182 mm.

2.

If the overall length of the inner duct is greater than 750 mm then a flue extension is required. To fit an extension refer to

the following section.

3.

Withdraw the inner flue duct from the outer air duct.

4.

Mark the outer air duct to match the length given above, measure from the end of the tube as shown in Figs. 12 and 13.

5.

Mark the inner flue duct to match the length given above.

6.

Cut both the inner and outer ducts to length.

Note: Do not cut the outer duct end with the two holes, these are for securing the terminal.

Ensure that all cuts are square and burr free.

7.

Fit the flue terminal to the outer duct by inserting it into the end with two holes. Align the holes and secure with the two

screws provided.

8.

Place the inner flue duct back into the outer duct.

9.

Pass the flue assembly through the wall (from inside or outside).

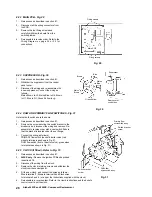

10. Position the seal and clamp (two screws), supplied with the bend, over the boiler flue adaptor. Fit the bend and rotate to

the correct position, then secure in position. See Fig 12.

Note: Ensure that the seal is located over both the bend and the flue adaptor.

11. Place the inner (no seal) duct clamp in position over the bend outlet as shown in Figs. 12 and 13, and position the outer

duct seal over the bend.

12. Push the outer duct into the wall slightly at the same time as pulling the inner duct towards the bend, inserting it fully into

the clamp on the bend. Tighten the clamp to secure the inner duct.

Note: Ensure the inner duct clamp screwed joint is at the bottom.

13. Pull the outer duct towards the bend. Check that the flue terminal protrudes 120 mm out of the wall, then position the seal

equally over the joint between the bend and the outer duct. Dismantle the clamp, position it over the seal and secure in

position.

14. Make good the inside and outside walls.

20

23

95

65

65

65

65

55

A

B

C

D

E

F

Summary of Contents for Alpha 240XE

Page 35: ...35 Alpha 240XP and 240XE Wiring Diagrams 9 2 ILLUSTRATED WIRING DIAGRAM Alpha 240XE ...

Page 36: ...36 Alpha 240XP and 240XE Wiring Diagrams 9 3 FUNCTIONAL FLOW WIRING DIAGRAM Alpha 240XP ...

Page 37: ...37 Alpha 240XP and 240XE Wiring Diagrams 9 4 FUNCTIONAL FLOW WIRING DIAGRAM Alpha 240XE ...