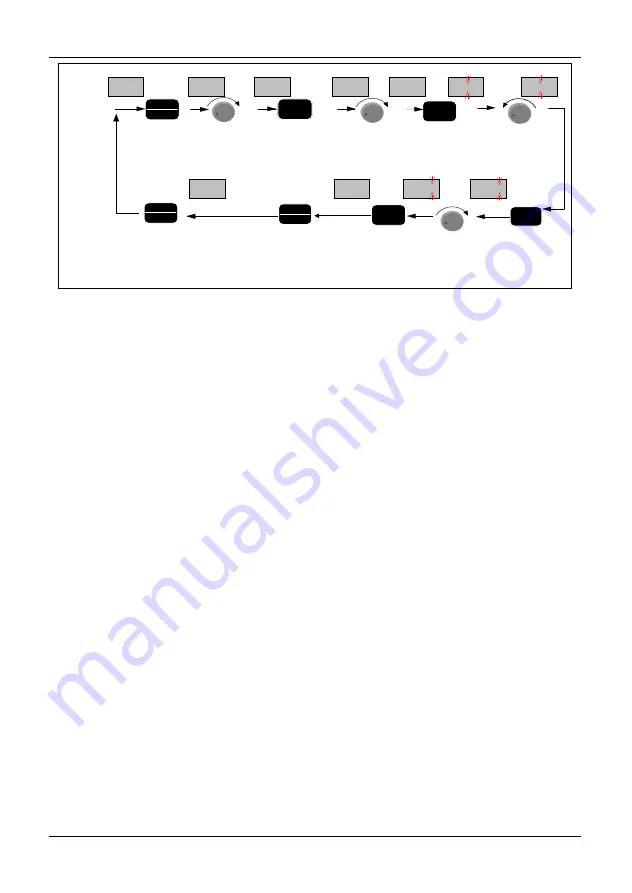

Chapter 3 Operation

25

0.00

P2.01

monitoring

state

go into

programming

state.display

parameter

group menu

Enter

into

parameter

code

number

menu

turn right 1

time,chose

parameter

code

number

P2.01

Enter into

parameter

value menu

Turn left 3

times to

chang the

number to 3

save the

changed value

and exit to

parameter

code number

menu

Display

of LED

Operation

of key

Shift to

change the

blinking

place to

right

Exit to

parameter

group

menu

Turn right 2

times to

change the

number to 2

Exit from

the

programming

state

turn right 2

times,chose

parameter

group

P2

P2.00

-P2-

-P0-

-P2-

P2.02

003.

2

003.

0

00

6

.0

00

3

.0

ENTER

PRG

ESC

ENTER

>>

PRG

ESC

PRG

ESC

ENTER

ENTER

+

+

+

-

Figure 3-5 Flow chart of parameter setting

In three-level menu state, no flicker digit for a parameter indicates that the function

code cannot be modified, and the possible reasons include:

Modifying the value is forbidden because the parameter is actual measure value,

or running record value or fixed value.

The function parameter cannot be changed when the driver is at running state.

However, it can be changed at stop state. So stop the driver and then change the

parameter value.

The driver parameters are protected. If function parameter value PF.01=1 or 2, the

parameters are forbidden to be changed. This parameter protection function is to

avoid operation mistake. To change the protection parameters, change value of

function code PF.01 to zero, then all the parameters can be changed

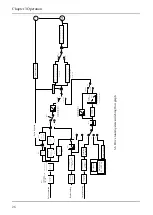

3.2 Flow chart of switching driver running

The flow chart of switching driver running is shown in Fig 3-6. CNC system uses the

pulse command and bipolarity analog AI2 or unipolarity analog AI1 to control

AS600M run in speed control mode . And CNC system uses the pulse command and

bipolarity analog AI2 to control AS600M run in position control mode. Position control

and speed control mode can be switched through the terminal X5 rigid tapping/pulse

position.

Summary of Contents for AS600M Series

Page 96: ...96 ...