9400001-J1 Rev F

44

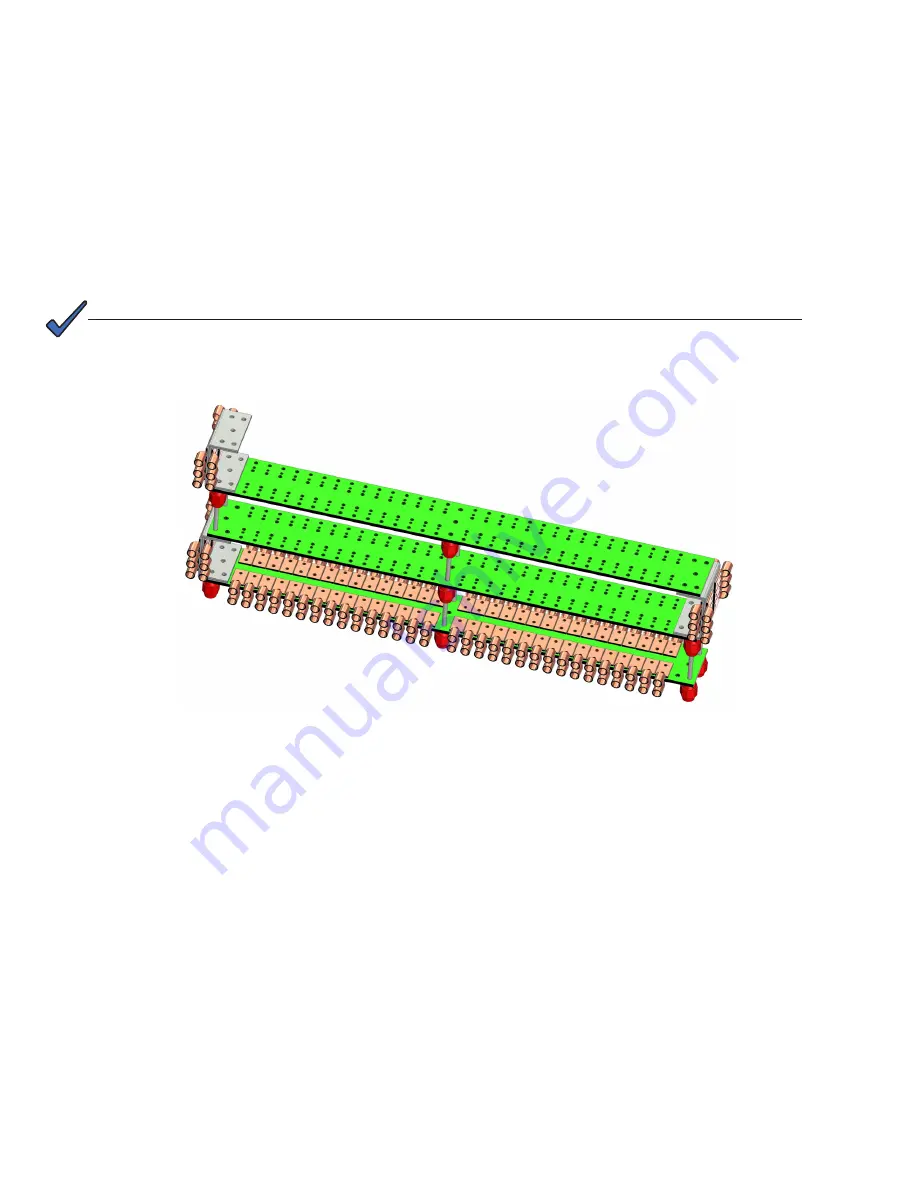

Figure 40 — External Battery Return Bar Kit

7.6 Mounting the Optional External Return Bar

The expandable external return bar kit (0380039-001) is an option for return connections for the loads and to serve

as the common connecting point for the positive side of the power bays and the batteries.

The base kit has a 4000A capacity.

1. Before joining return bar components together, ensure that all contact surfaces on the busbars are clean and

coated with a thin coat of NO-OX-ID “A” compound (or approved equivalent).

2. Follow the instructions included with the kit (0380039-F0), to assemble and mount the kit on a customer-

supplied auxiliary framing superstructure away from the system.

NOTE:

Requires customer supplied auxiliary frame (2 " x 9/16").