27

Alpine TR42 Direct Vent Gas Fireplace

OPERATING INSTRUCTIONS

1) The first fire in your fireplace will help cure the painted

surfaces. To ensure that the paint is properly cured, it is

recommended that you burn your fireplace for at least

four (4) hours the first time you use it with the fan on.

When first operated, the unit will release an odor caused

by the curing of the paint and other components. Smoke

detectors may go off during this initial break-in period.

Open windows or doors in the area of the fireplace to

allow for ventilation during the break-in period.

OPERATING INSTRUCTIONS

NOTE: When the fireplace is cold and the appliance is

first lit, it may cause condensation and fog the glass. This

condensation is normal and will disappear in a few min-

utes as the glass heats up.

2) Read and understand these instructions completely be-

fore attempting to operate this appliance.

3) Be sure that all items in this installation portion of this

manual have been properly completed in compliance to

local codes and this manual.

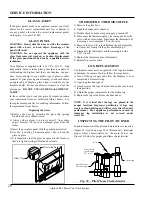

LIGHTING PROCEDURE

1) Turn burner OFF using the “ON/OFF” switch or by

turning the thermostat or remote control to the “OFF”

position.

2) Turn gas control knob so indicator points to “OFF”

position and allow 5 minutes for any gas in the

combustion chamber to escape.

3) Turn the gas control knob counterclockwise so the

indicator points to the “PILOT” position. Depress the

gas control knob fully. Depress the igniter button several

times until the pilot lights. After approximately one

minute, release the gas control knob. The pilot flame

should continue to burn. If the pilot does not remain lit,

repeat operation allowing a longer period before

releasing gas control knob.

4) When the pilot stays lit, turn the gas knob further

counterclockwise to the “ON” position.

5) Use the wall switch, thermostat or remote control to turn

on the unit.

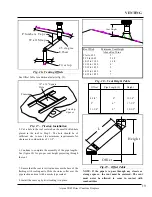

6) Rotate the flame height regulator to adjust the flame

height higher or lower.

1) Use the wall switch, thermostat or remote control to

turn off the main burner.

2) Turn the main gas control clockwise to the “OFF”

position

SHUTDOWN PROCEDURE

FIREPLACE MAINTENANCE

1) Before performing any service on the appliance,

ensure the gas has been completely shut off, the unit

cooled, and the electricity shut off to the appliance.

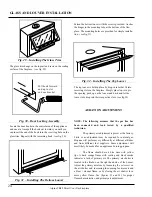

2) The burner and valve control compartments must be

cleaned annually. A vacuum with a brush attachment

works well. The logs should be cleaned gently with a

soft bristle brush. The logs are fragile and are easily

damaged.

3) Clean the appliance with a damp cloth. Never use

abrasive cleaners. The glass should be cleaned with a

gas fireplace glass cleaner. The glass will slowly build

a thin white film on the inside. This film is normal

and can be removed using a fireplace glass cleaner

available at your local dealer.

4) The fireplace is finished with a high temperature paint.

If your fireplace needs to be repainted or touched up,

see your local dealer for StoveBright Paint.

5) The appliance and the venting system must be

inspected before use, and at least annually, by a

qualified field technician. The vent must be inspected

to ensure that the flow of combustion air and

ventilation air is not obstructed.

6) Do not use this appliance if any part has been under

water. Immediately call a qualified service technician

to inspect the appliance and to replace any part of the

control system and any gas control which may have

been under water.

7) If the venting system is disassembled for any reason it

must be properly resealed as per the instructions in the

venting section of this manual. Never operate the

appliance if the venting system is not properly sealed.

8) The blower system requires annual lubrication. The

blower is marked with lubrication points. Use a good

quality light machine oil for lubrication. Apply three

drops per port annually.

GOLD PLATED or STAINLESS TRIMS

The gold plate or stainless trims on the fireplace require

little maintenance. If the pieces get fingerprints or dust

build-up, you should use a damp cloth only for cleaning.

DO NOT use cleaners of any type on the stainless or

gold. Be sure to clean any fingerprints off of the unit BE-

FORE turning the fireplace on.

E

A

p

ilo

t

on

off

LO

HI