Installation

Bolting and Tightening torques

S31--001EN05

3/4

02--2011

© ALSTOM 2010. All rights reserved. Information contained in this document is indicative only. No representation or warranty is given or should be

relied on that it is complete or correct or will apply to any particular project. This will depend on the technical and commercial circumstances. It is

provided without liability and is subject to change without notice. Reproduction, use or disclosure to third parties, without express written authority, is

strictly prohibited.

GRID

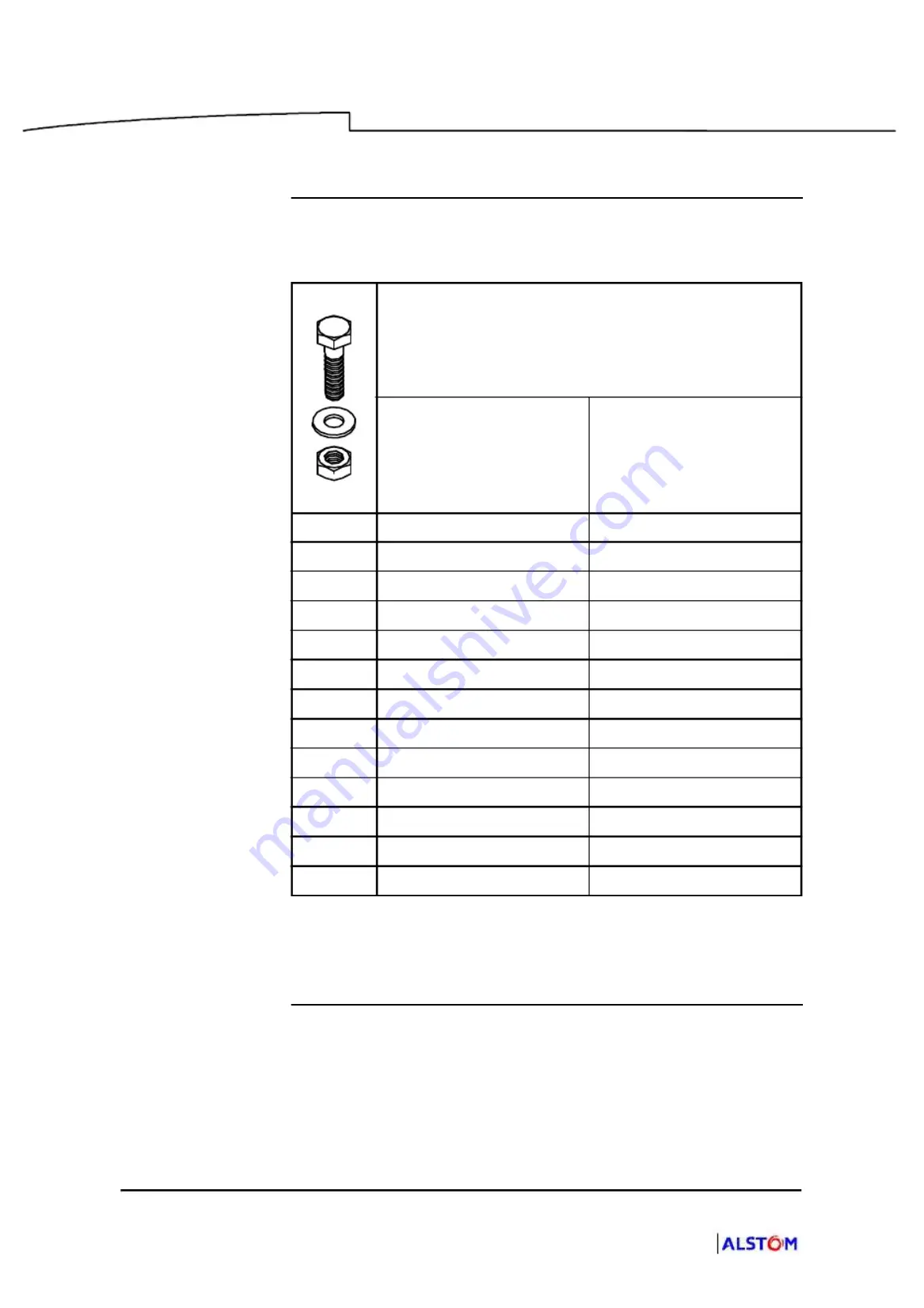

Tightening torques values

Values table

The tool and the tightening method must be such that the torque actually ap-

plied to the screw head corresponds with the reference torque shown in the

table below, to within a tolerance of

±

20%.

TIGHTENING TORQUES

in

daN.m

STEEL SCREWS

CLASS 6.8

or

STAINLESS A2--70, A4--70

CLASS 8.8

or

STAINLESS A2--80, A4--80

M2,5

0,05

0,06

M3

0,09

0,11

M4

0,19

0,26

M5

0,38

0,51

M6

0,66

0,88

M8

1,58

2,11

M10

3,20

4,27

M12

4,97

6,63

M14

8,67

11,56

M16

13,42

17,90

M20

26,22

34,98

M24

45,68

60,93

M30

90,44

120,65

Example

For a theorical torque of 5 daN.m, the tightening torque can be applied from

4 daN.m to 6daN.m.

Summary of Contents for FKG1X

Page 2: ......

Page 7: ...GRID High Voltage Switchgear This page is intentionally blank...

Page 13: ...GRID High Voltage Switchgear This page is intentionally blank...

Page 17: ...GRID High Voltage Switchgear This page is intentionally blank...

Page 21: ...GRID High Voltage Switchgear This page is intentionally blank...

Page 75: ...This page is intentionally blank This page is intentionally blank...