Maintenance

Maintenance plan

G51--001EN07

8/18

02--2011

© ALSTOM 2010. All rights reserved. Information contained in this document is indicative only. No representation or warranty is given or should be

relied on that it is complete or correct or will apply to any particular project. This will depend on the technical and commercial circumstances. It is

provided without liability and is subject to change without notice. Reproduction, use or disclosure to third parties, without express written authority, is

strictly prohibited.

GRID

Maintenance operations of disconnector, earthing switch, and (or) starting dis-

connector

(where applicable)

(10000 guaranteed mechanical cycles)

Guide

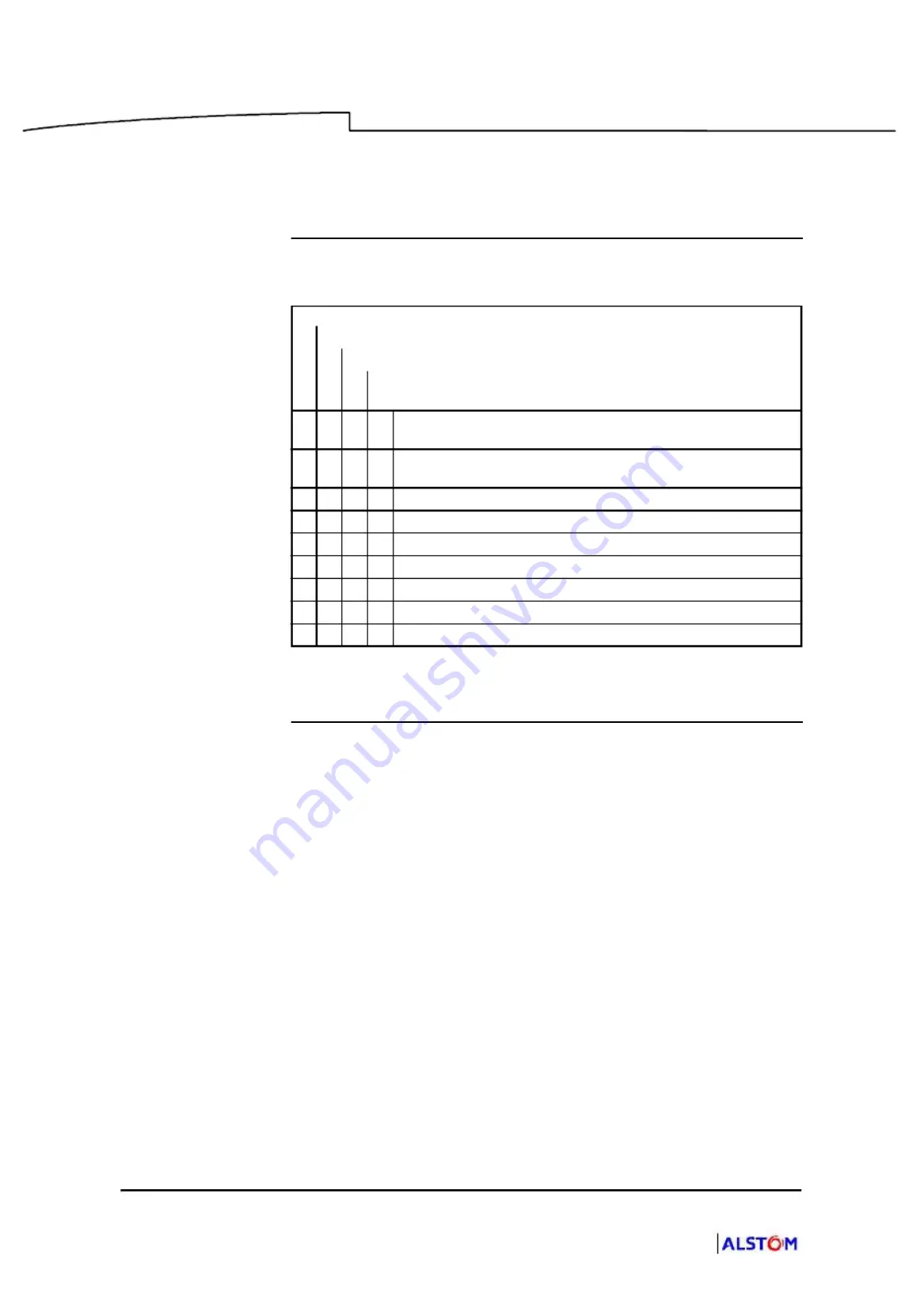

The table below is a guide of the operations to be carried out at each mainte-

nance stage :

MAINTENANCE VISITS

(1 or 2 times a year)

INSPECTION

(every 5 years)

OVERHAUL

(OPERATING TIME : 20 years)

INTERVENTION ON AN EARTHING SWITCH

(following a guaranteed maximum short--circuit)

` J J

Check general condition of equipment : visual aspect (corro-

sion, paint,...).

` J J

Check the condition of crank lever assembly (axles, retaining,

clips,...).

` J J

Check control mechanism (CMK).

J J

Check tightening of elements (frame,cubicle,...).

J J

Inspect the insulating supports of poles.

` J

Inspect contacts.

` J

Measure pole operating times.

` J

Measure resistance of main contact.

J

Replace the earthing switch

Legend : (

J

Compulsory) (

`

Recommended)

Summary of Contents for FKG1X

Page 2: ......

Page 7: ...GRID High Voltage Switchgear This page is intentionally blank...

Page 13: ...GRID High Voltage Switchgear This page is intentionally blank...

Page 17: ...GRID High Voltage Switchgear This page is intentionally blank...

Page 21: ...GRID High Voltage Switchgear This page is intentionally blank...

Page 75: ...This page is intentionally blank This page is intentionally blank...