9

4. Getting started

You can start a measurement

•

with temp gard as data logger

- according to the standard settings for the

measurement parameters

- change of the measurement parameters

in the setup menu measurement parame-

ters

•

by loading an Organizer

The measurement with the temp-gard as a data

logger is described in the following.

The measurement with an organizer loaded is

described in the temp-chart manual.

4.1 Starting the temp-gard logger

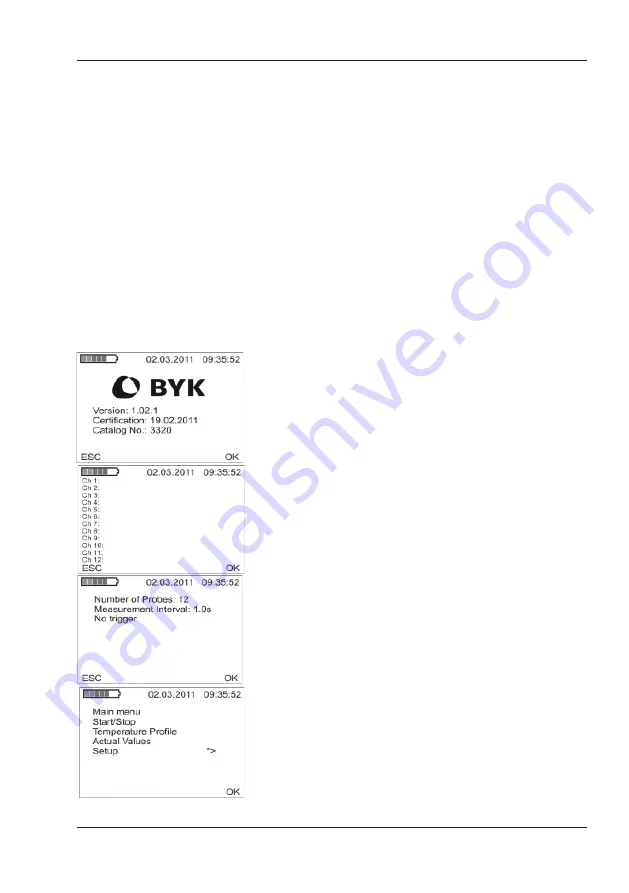

When the temp-gard logger is switched on, the

status of the setup settings will be displayed:

Screen 1: Firmware version, Certification and Cat.

No.

Screen 2: Ch xx: Probe name, press OK

Screen 3: No. of Probes – Measurement interval –

Trigger

Screen 4: Menu Connect the thermocouple probes

to the temp-gard instrument.

Start the measurement by pressing the start/stop

key.

Note:

Make sure that the thermal barrier and the

heat sinks have cooled down completely after the

previous measurement.

Make sure that the heat sinks are inserted in both

halfs of the thermal barrier.

Place the temp-gard in the lower part of the ther-

mal barrier.

Make sure that all gaskets are clean and without

defects.

Place the temperature probe cables side by side

on the gasket of the thermal barrier and lock the

box with the upper part.

Attach the thermocouple probes to the object.

Getting started