SECTION 1 GENERAL

INFORMATION

1.1

MODEL DESCRIPTION

The CO2-PG80 Purge Gas Generator is designed to remove

water and CO

2

from a compressed air stream. This is done by

passing the air through beds of adsorbent media (using 13X

molecular sieve) which adsorbs both H

2

O and CO

2

.

1.2

SERIAL NUMBER CODING

1.3

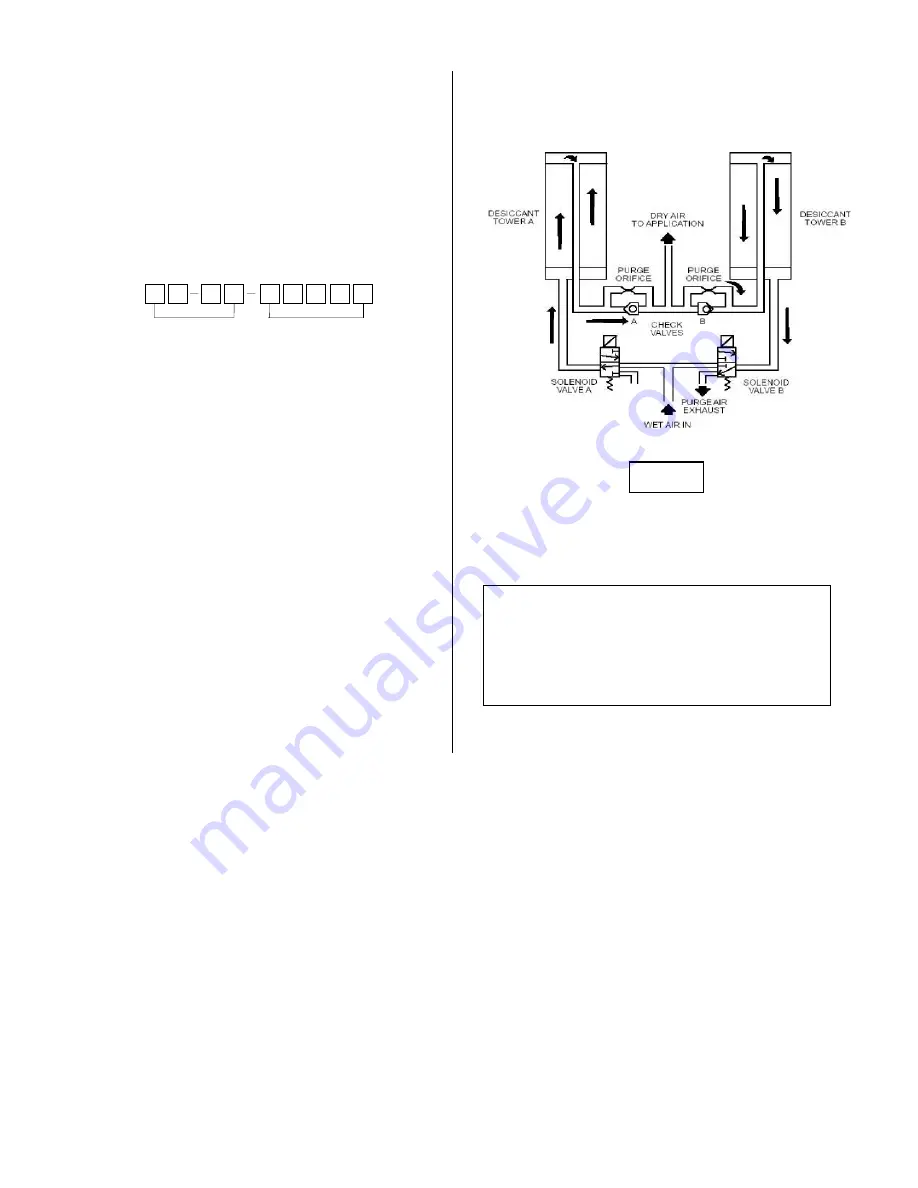

DESCRIPTION OF OPERATION

The CO2-PG80 Purge Gas Generator uses the pressure swing

adsorption method of gas separation. This requires two

identical towers containing beds of adsorbent desiccant media.

Incoming wet, CO

2

rich air enters the adsorber/dryer through

the inlet port, where energized SOLENOID VALVE A directs

the pressurized air stream to the bottom of DESICCANT

TOWER A containing active adsorbent. This adsorbent media

bed removes water vapor and CO

2

gas from the air to better

than -100°F dew point and less than 1 PPM CO

2

when

operated at catalog conditions. The dry and CO

2

free air

leaving the top of DESICCANT TOWER A is directed to the

outlet through open CHECK VALVE A. PURGE ORIFICE B

and closed CHECK VALVE B allow a metered portion of the

processed air to flow into DESICCANT TOWER B being

regenerated. The open purge port on deenergized SOLENOID

VALVE B and the purge orifice reduce the pressurized dry air

down close to atmospheric pressure and regenerate the

adsorbent media by removing the accumulated water vapor

and CO

2

and carrying it out the open purge port.

The two solenoid valves are controlled by a solid state timer.

After 30 seconds, the media in DESICCANT TOWER B is

regenerated, and the solid state cycle timer causes the process

to instantly reverse, with TOWER B adsorbing and TOWER A

regenerating.

The

following

flow

schematic

(FIG

1)

demonstrates the adsorber/dryer operation.

FIG 1

SOLENOID VALVE TIMING CYCLE

30 seconds per side continuous

1 minute total cycle time

P/N P013253 REV B

MONTH/YEAR OF MANUFACTURE

SERIAL #