Altec AIR CO2-PG80 Purge Gas Generator Operations and Maintenance Manual

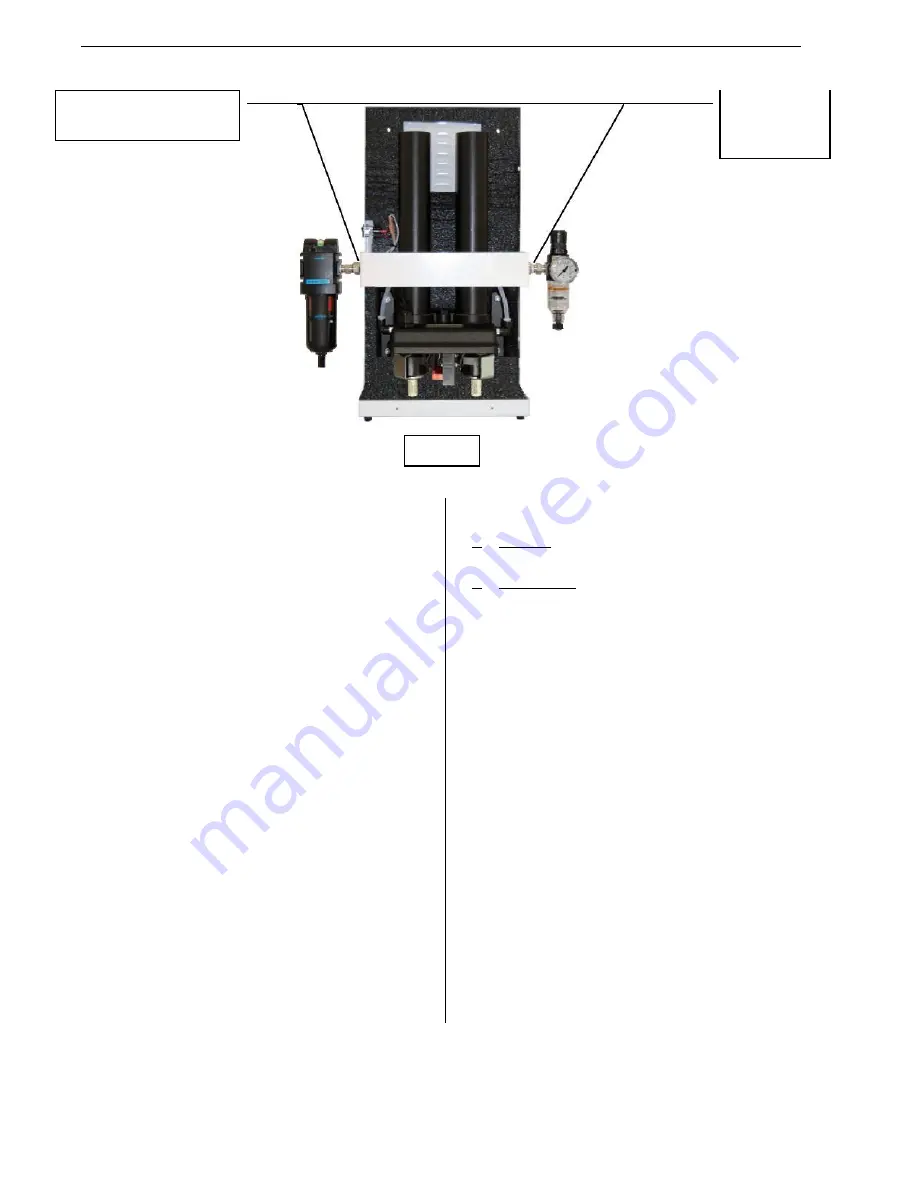

INLET BULKHEAD

FITTING

OUTLET

BULKHEAD

FITTING

FIG 2

SECTION 4 INSTALLATION

4.1

PARTS INCLUDED

(1) CO2-PG80 Purge Gas Generator

(1) Inlet Coalescing Filter Assy.

(1) Outlet Filter Regulator Assy.

(6) Cover Screws, 6-32 x 3/8, PH, SS

(1) Operations & Maintenance Manual

4 .2 LO C AT IO N

DO NOT INSTALL THE UNIT IN AN ENVIRONMENT OF

CORROSIVE CHEMICALS, EXPLOSIVE GASES, OR AREAS

OF HIGH OR LOW AMBIENT TEMPERATURE (ABOVE 125°F

OR BELOW 33°F).

Install the unit indoors. Unit may be wall mounted or placed on

a table top.

4.3

INSTALL FILTERS

A coalescing filter is provided to be installed on the inlet to the

adsorber/dryer to remove entrained particulates, liquid moisture

and oil which can cause damage to the desiccant beds. A

particulate afterfilter is provided to be installed on the outlet of

the adsorber/dryer to remove any adsorbent media dust that

may migrate from the desiccant beds.

Using a wrench to keep inlet bulkhead fitting from turning,

install Inlet Filter Assy to left side of unit as shown in FIG 2

above. Similarly, install Outlet Filter Regulator Assy to Right

Side of unit.

4 . 4 M O U NT I N G

1.

Table top

a.

The unit comes with rubber feet installed on bottom

of cabinet for use on table top.

2.

Wall mounting

a.

Remove (6) cover screws and remove cover. While a

helper holds the unit at the mounting location, mark

the position of the (4) mounting holes at the back of

the cabinet.

Mount the cabinet

using these

mounting holes. Be sure to use proper wall mounting

anchors if mounting in drywall.

b.

Reinstall cover.

4.5

ELECTRICAL CONNECTIONS

Before plugging in unit, check the unit nameplate for electrical

characteristics. Standard electrical characteristics are 115

volt, 1 phase, 50/60 Hz. Models operating on 230 volts are

available.

IMPORTANT!: No overload protection is provided in the

adsorber/dryer and unit should be plugged/wired into a

protected circuit.

4.6

PIPING AND CONNECTIONS

Inlet and outlet tubing should be appropriate for pressure and

temperature of operation.

See specification chart for

inlet/outlet NPT thread size. Teflon tape should be used in the

makeup of joints to ensure a good, airtight fit of piping

components. Check all connections for leakage using soap

solution prior to putting unit into service.

Page 4

P/N P013253 REV B