Commissioning

Instruction manual 91/104 V9.2

•

SLAVE: The “anti-backlash” function is active and the drive works as a SLAVE motor. Only signals from the motor

transducer and the connection cable to the master drive must be connected to this drive.

•

MASTER 2: The “anti-backlash” function TYPE 2 is active and the drive works as a MASTER motor. All references and

commands coming from the CNC or PLC will be connected to this drive.

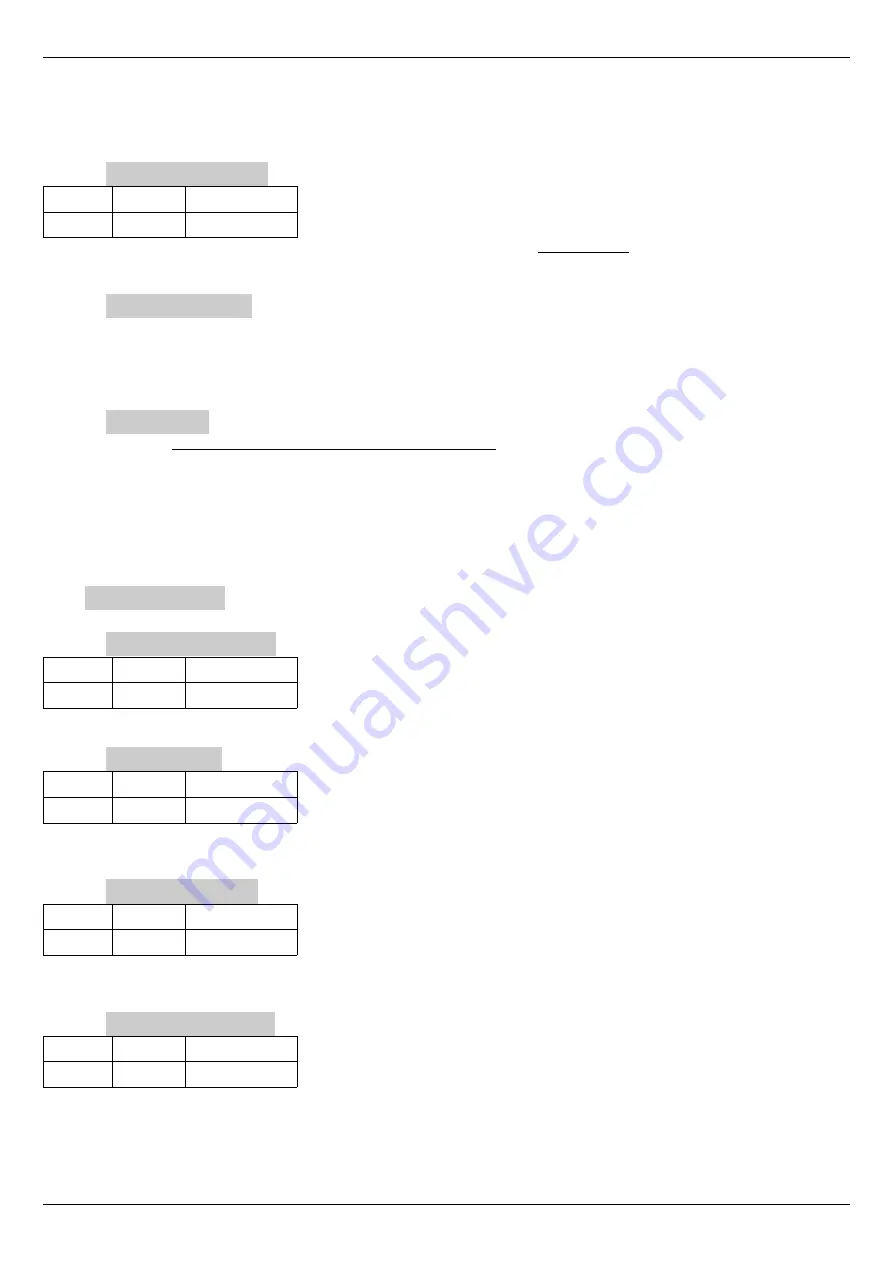

Contrast Torque

Minimum Maximum Units of measure

0.0

+50.0

%

This menu appears only in the “Master” drive. The parameter is used to set the contrast

torque

in anti-backlash mode with a value

proportional to the maximum torque that can be delivered from the motor to the current speed. Normally a value between 5 and 30 %

is used.

Slave Running

This menu appears only in the “Master” drive. The parameter is used to enable or disable the operation of the motor “Slave” and you

can only change it when the master drive is disabled. Normally it is set to "Enabled" and automatically returns to this setting each time

you drop voltage to auxiliary services or when you switch the ”AntiBack Mode“ parameter (see page 49). The purpose of this

parameter is to allow the master motor to run even when it is not mechanically connected to the slave motor, when you want to

optimise the adjustment loops.

Net Errors

This menu is used to disable the control of any short communication errors between master and slave. If the alarm appears during op-

eration Anti backlash data error (see page 77) the cause may be due to disturbances that are generated by unshielded cables or other

equipment nearby on the twisted double of the communication bus.

Disabling error control on the communication bus shall not affect the safety of operation: in fact, other controls are still active that

come into operation if the communication between master and slave is interrupted or that the data exchanged is not consistent within a

time of 1 ms.

If, despite the disabling of these controls, the alarm "Anti backlash data error“ continues to appear, then it is necessary to make sure

that the disturbances are reduced.

Position Loop

Menu group with parameters relative to the position loop that is activated with the input assigned to the “Position Zero " function.

It’s Proport. Gain

Minimum Maximum Units of measure

0

9.000

-

This parameter modifies the response speed to the angular position change when positioning the motor shaft is controlled. Too high a

value can create instability and vibration; in this case try to reduce it until you get the right positioning but without oscillations.

Integr. Gain

Minimum Maximum Units of measure

0

2.0000

-

This parameter modifies the accuracy with which the motor reaches the controlled position. Too high a value can create instability and

vibration; in this case try to reduce it until you get the right positioning but without oscillations. In most cases the standard value is

sufficient; in some cases it may be better to set it to the ZERO value.

Position Speed

Minimum Maximum Units of measure

10

999

RPM

This parameter modifies the motor’s maximum rotation speed during the positioning phase. A higher value makes the positioning

more “nervous " and stressful for the mechanics but could trigger vibrations or inability to position correctly if the motor inertia is

high.

Position Window

Minimum Maximum Units of measure

0

2.00

Degrees

With this parameter you set a tolerance on the position to be reached to signal on a digital output the signal of “Position reached ".

50

Alter Elettronica s.r.l.