Commissioning

Instruction manual 91/104 V9.2

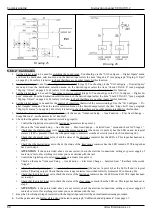

5.6.3.2 Calibration

1. First of all you have to decide whether the motor over-temperature signal must be managed by the CNC or the drive and set

the parameter in the “Advanced Setup → Aux Function → Motor Overtemp → Signal Mode” menu in one of the following

ways:

1. DIG.OUT ONLY: The drive does not

stop

, but only signals the intervention of the PTC on the digital output. It must be

the CNC or PLC that stops the motor when it considers it possible.

2. DRIVE FAULT: The drive reports PTC intervention on the digital output and with a message on the display (see

message ”Warning!!! Motor Overtemp.“ on page 83). If the CNC or PLC does not stop the motor within the time set in

the “Drive FLT delay” parameter, the drive locks and disables the motor, signaling the alarm ”Motor Overtemperature“

and take the digital output "DOK" to the logical level "0”.

2. Set on which digital output you want to exit the over-temperature signal of the motor; In the configuration menu "I/O

Configure → Digital Outputs" and from the selection menu of the source of the desired output go to select the input "Motor

Temp." (see paragraph ”Dig.Op. X source“ on page 44). If you want to change the logical state of the temperature signaling

output, insert (or disconnect) the logical reversal setting of the output (see paragraph ”Dig.Op. X Sign“ on page 45).

Normally when the motor is overheated, the associated output goes logically “0”.

3. If the “Drive Fault” mode has been selected in point 1, then you must also set the parameter “Advanced Setup → Aux

Function → Motor Overtemp → Drive FLT delay”. With this value you set the delay from the over-temperature signal (i.e.

when the PTC opens) to when the drive stops and stops the motor signaling the alarm ”Motor Overtemperature”.

5.6.4 Speed threshold

5.6.4.1 Generality

This function is used to signal on a selectable digital output (usually matched to the DO2 output), when the motor has exceeded a cer -

tain set speed. If the motor speed is above the threshold for a time greater than 500 mSec the signaling and the associated output

changes logical status and leads to +24V or 0V if the inversion of sign is activated (see "Dig.Op. X Sign“ on page 45).

5.6.4.2 Calibration

The only calibration to do is setting the speed threshold you want to have (standard: 30 RPM) by going to the menu "Advanced Setup

→ Aux Function → Speed Threshold → Threshold n.1" and changing the number written for the threshold to be changed (see

paragraph ”Threshold No. 1” on page 48).

To use it you have to go to the configuration menu "I/O Configure → Digital Outputs" and from the selection menu of the source of

the desired output go to select the item "Speed Thresh. X“ (see paragraph ”Dig.Op. X source“ on page 44). If you want to change the

logical state of the output when the motor exceeds the threshold, you must enter (or disconnect) the logical reversal setting of the

output (see paragraph ”Dig.Op. X Sign“ on page 45).

5.6.5 Maximum load reporting

5.6.5.1 Generality

This function is used to signal on a selectable digital output (usually matched to the DO3 output), when the motor has almost reached

the maximum load: in this case it is advisable to reduce the load otherwise the speed of the motor shaft could be lowered and no

longer controlled. When the load applied on the motor exceeds 90 % of the maximum load, the associated signaling and output

changes logical status and leads to +24V or 0V if the inversion of sign is activated (see "Dig.Op. X Sign“ on page 45).

5.6.5.2 Calibration

This function does not need calibration. To use it you have to go to the configuration menu "I/O Configure → Digital Outputs" and

from the selection menu of the source of the desired output go to select the item "Peak Mot. Load“ (see paragraph "Dig.Op. X source“

on page 44). If you want to change the logical state of the output when the motor is at the maximum torque, you must insert (or

disconnect) the logical reversal setting of the output (see paragraph "Dig.Op. X Sign“ on page 45).

5.6.6 Speed reached

5.6.6.1 Generality

This function is used to signal on a selectable digital output, when the motor has reached the required speed. If the speed difference

between the actual motor and the required speed is lower than the threshold for a time greater than 500 mSec the signaling and the

associated output changes logical state and leads to +24V or 0V if the inversion of sign is activated (see ” Dig.Op. X Sign“ on page

45).

5.6.6.2 Calibration

The only calibration to do is setting the speed difference threshold you want to have (standard: 2 %) by going to the "Advanced Setup

→ Aux Function → Speed Reached" menu and changing the written number (see paragraph ”Speed reached” on page 48).

66

Alter Elettronica s.r.l.