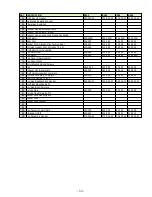

Appendix D: Troubleshooting Guide

is guide is intended to help you diagnose and repair basic problems with you boiler. If you believe your

problem is serious or the problem persists a9er following all the procedures speci ed in this guide, contact

AHS for support.

Problem

Possible Cause

Solution

1. Boiler overheating

a) Control malfunction

b) Incorrect control setting

c) Intake air valve not closing properly

d) Excessive chimney draft

e) Load door not sealing properly

a) Replace malfunctioning control

b) Adjust control setting

c) Replace gasket or adjust linkage

d) Reduce draft or see e)

e) Adjust load door for proper seal,

replace gasket if necessary

2. Back-puffing (Also see section on

Charging Boiler with Wood and the

Back-Puffing Checklist)

a) Burn cycle too long/Too much wood

b) Wood too small and/or excessively

dry

c) Improper loading of fire box

d) Improper starting of wood

a) Fill with less wood to shorten burn

cycle

b) Load larger fuel with higher moisture

content

c) Follow proper loading procedure

d) Follow proper starting procedure so

as to attain high refractory

temperatures

3. Smoke visible at stack

a) Refractory not hot enough

b) Refractory not properly sealed in

fuel chamber

c) Center cleanout plug not properly

sealed

d) Leaking load door

e) Leaking air valve

f) Ash or charcoal buildup on or in

refractory

a) Allow refractory to come up to

operating temperature; refer to

instructions for building a fire

b) Seal refractory with “Trowleze”

refractory cement.

c) Replace damaged ceramic pad at

center cleanout plug

d) Check doors for airtight seal

e) Repair/replace air valve gasket disc

f) Clean ash from boiler. See “weekly

maintenance routine”

4. Fire goes out

a) Boiler not cycling frequently enough

(refractory cools to below kindling

temperature)

b) Wood bridging in fuel chamber

a) Increase heat load or install draft

cycle timer (contact AHS)

b) Reposition wood (always load wood

length-wise front to back in

chamber)

5. Smoke leakage at doors

a) Improper gasket seal

b) Door not tight enough, or is out of

adjustment

a) Repair seal with high temperature

RTV sealant added at low point on

door gasket

b) Adjust door

6. Fan vibration

a) Bearing or motor loose

b) Fan out of balance

c) Creosote buildup in area of fan

impeller

a) Tighten all bolts

b) Inspect fan for damage

c) Raise return water temperatures or

use drier wood

7. Excessive water in the cyclone

drawer (Also see condensation

checklist)

a) The stack temperature may not be

high enough.

b) The fire box is being filled too full for

the heat demand.

c) There may be a blockage in the flue,

cyclone, heat exchanger, or refractory.

d) The wood logs are too large and/or

has high moisture content.

e) Load door seal or air valve seal is

leaking

a) The boiler should be in an insulated

room. The flue stack needs to be

insulated (If the room is typically

cold.)

b) Fill the fire box only half full or

enough to burn for eight hours or

less (shorten cycles).

c) Remove ash from fire box and

refractory. Clean the heat

exchanger, cyclone, or flue.

- 60 -

Summary of Contents for wood gun E100 SF

Page 2: ......

Page 24: ...Photo Smoke flap installed 19 ...

Page 46: ...Steel Center Brick 8 Inch 41 ...

Page 49: ...Appendix A Boiler Specification Diagram 44 ...

Page 50: ... 45 ...

Page 51: ... 46 ...

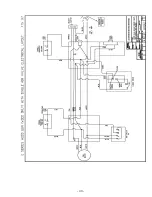

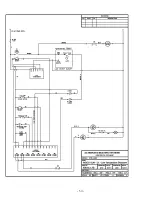

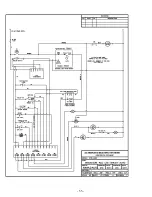

Page 53: ...Appendix B Wiring Diagrams 48 ...

Page 54: ... 49 ...

Page 55: ... 50 ...

Page 56: ... 51 ...

Page 57: ... 52 ...

Page 58: ... 53 ...

Page 59: ... 54 ...

Page 60: ... 55 ...

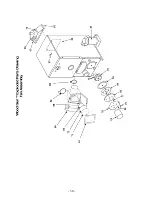

Page 61: ...Appendix C Exploded Parts Drawings 56 ...

Page 63: ... 58 ...

Page 68: ...Appendix F Boiler Piping and Ducting Examples 63 ...