Operation & Care Manual #843 • 9.

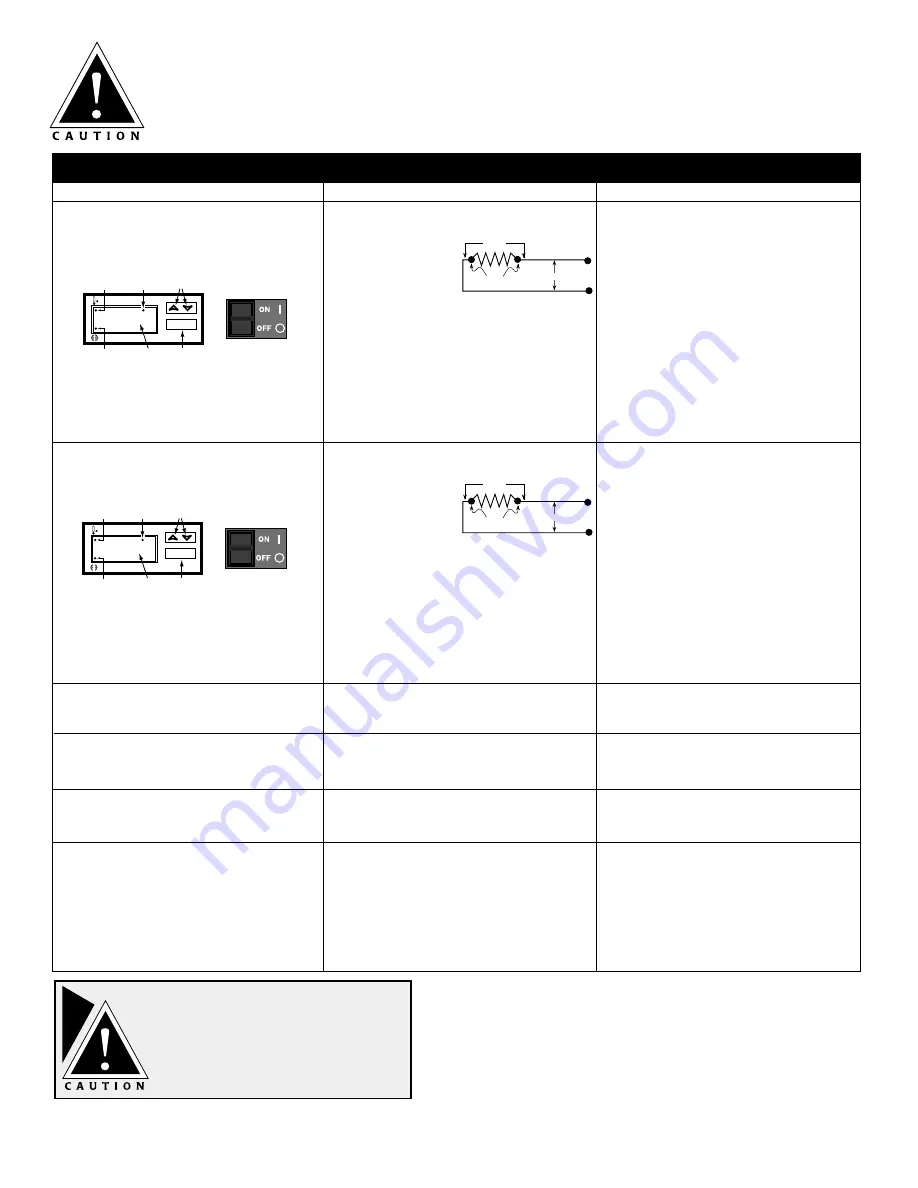

Error Code

1

. Control displays "OOO".

2. Control displays "CCC".

3. Unit does not operate.

4. No display in electronic control.

5. Cannot control temperature but sensor

and electronic control check OK.

6. Temperature readout incorrect.

Possible Cause

A. Sensor is open circuited.

B.

Associated wiring is open circuited.

C.

Control is faulty.

A.

Sensor is short circuited.

B.

Associated wiring is short circuited.

C.

Control is faulty.

A.

Insufficient power supply.

B.

Defective power cord or plug.

A.

Faulty power supply board.

B.

Faulty electronic control.

A.

Faulty relay.

B.

Heating element sensor.

A.

Dirty or faulty sensor.

B.

Faulty control.

Action Required

Detach the sensor from the terminal block.

Use an Ohm meter to measure the resistance

of the sensor. Check sensor at 32°F (0°C)

using a container of ice water. If Ohm read-

ing is 100, replace display. If Ohm reading is

not 100, replace sensor.

Check wires for integrity. Check for proper

and secure connections at the thermostat and

terminal block. If necessary, re-secure the

faulty connections.

Energize system after the above steps have

been completed. If control still reads

"OOO", contact factory.

Detach the sensor from the terminal block.

Use an Ohm meter to measure the resistance

of the sensor. Check sensor at 32°F (0°C)

using a container of ice water. If Ohm read-

ing is 100, replace display. If Ohm reading is

not 100, replace sensor.

Check wires for integrity. Check for proper

and secure connections at the thermostat and

terminal block. If necessary, re-secure the

faulty connections.

Energize system after the above steps have

been completed. If control still reads

"CCC", contact factory.

Check power source.

Check and replace if necessary.

Check line voltage for 24V across pins 6 and

7 on the power supply board.

Replace control.

Replace relay.

Replace element.

Detach the sensor from the terminal block.

Use an Ohm meter to measure the resistance

of the sensor. Check sensor at 32°F (0°C)

using a container of ice water. If Ohm read-

ing is 100, replace display. If Ohm reading is

not 100, replace sensor.

This chart is provided for the assistance of

qualified technicians only

and is not intended for use by untrained or

unauthorized service personnel. If your unit is not operating properly, check the following before calling your

authorized service agent. Check the power applied to the unit. Plug in outlet? Fuse OK?

Do not attempt to repair or service beyond this point. Contact manufacturer for nearest authorized service agent.

Repairs made by any other service agent without prior authorization by manufacturer will void the warranty on the unit.

Tr o u b l e S h o o t i n g G u i d e

DISCONNECT UNIT

FROM POWER SOURCE

BEFORE CLEANING OR

SERVICING.

EXT. WIRES

SENSOR

T-BLOCK

CONNECTORS

EXT. WIRES

SENSOR

T-BLOCK

CONNECTORS

SET

prg

!

°

F

ERROR CODE

INDICATOR L.E.D.

HEAT

INDICATOR L.E.D.

ERROR

CODE

DISPLAY

TEMPERATURE

SET

BUTTON

L.E.D.1

INCREASE/DECREASE

ROCKER BUTTON

ooo

POWER

ON/OFF

ROCKER SWITCH

SET

prg

!

°

F

ERROR CODE

INDICATOR L.E.D.

HEAT

INDICATOR L.E.D.

ERROR

CODE

DISPLAY

TEMPERATURE

SET

BUTTON

L.E.D.1

INCREASE/DECREASE

ROCKER BUTTON

CCC

POWER

ON/OFF

ROCKER SWITCH

Summary of Contents for 1000-HCM

Page 14: ...Operation Care Manual 843 13...

Page 15: ...Operation Care Manual 843 14...