Operation & Care Manual #843 • 1.

U N P A C K I N G a n d S E T - U P

The Alto-Shaam Hot &

Cold Merchandiser has been

thoroughly tested, checked

for calibration, and inspected

to insure only the highest

quality cabinet is provided. When you receive your

cabinet, check for any possible shipping damage and

report it at once to the delivering carrier.

See

Transportation Damage and Claims

section located in this manual.

The cabinet, complete with unattached items and

accessories, may be delivered in one or more pack-

ages. Make certain the number of packages received

matches the packing list and the accompanying bill

of lading.

Save all the information and instructions packed

inside the cabinet. Complete and return the warran-

ty card to the factory as soon as possible to insure

prompt service in the event of a warranty parts and

labor claim.

The unit should NOT be used in any area where it

may be affected by steam, grease, dripping water,

high temperatures, drafts from ventilator openings,

radiant heat from light fixtures that are too close or

any other severely adverse conditions. The case is

designed to be used in areas that maintain a temper-

ature at or below 75°F (24°C) dry bulb and a 55%

relative humidity. The case must be installed level in

order for the drain in the refrigerated section to work

properly.

The unit must be bolted to its base. In order to

maintain standards established by the National

Sanitation Foundation, stationary models mounted

directly on top of an base must be sealed to both the

base and the floor with a R.T.V. or silastic meeting

N.S.F. requirements. Counter and table units must

be mounted on legs of a sufficient 4" height to pro-

vide minimum unobstructed space beneath the unit.

Any countertop mounted installations must have

adequate ventilation at the bottom of the unit for

proper air circulation.

(Refer to counter layout in this

manual).

NOTE:

Any claims for warranty must include

the full model number and serial number

of the cabinet.

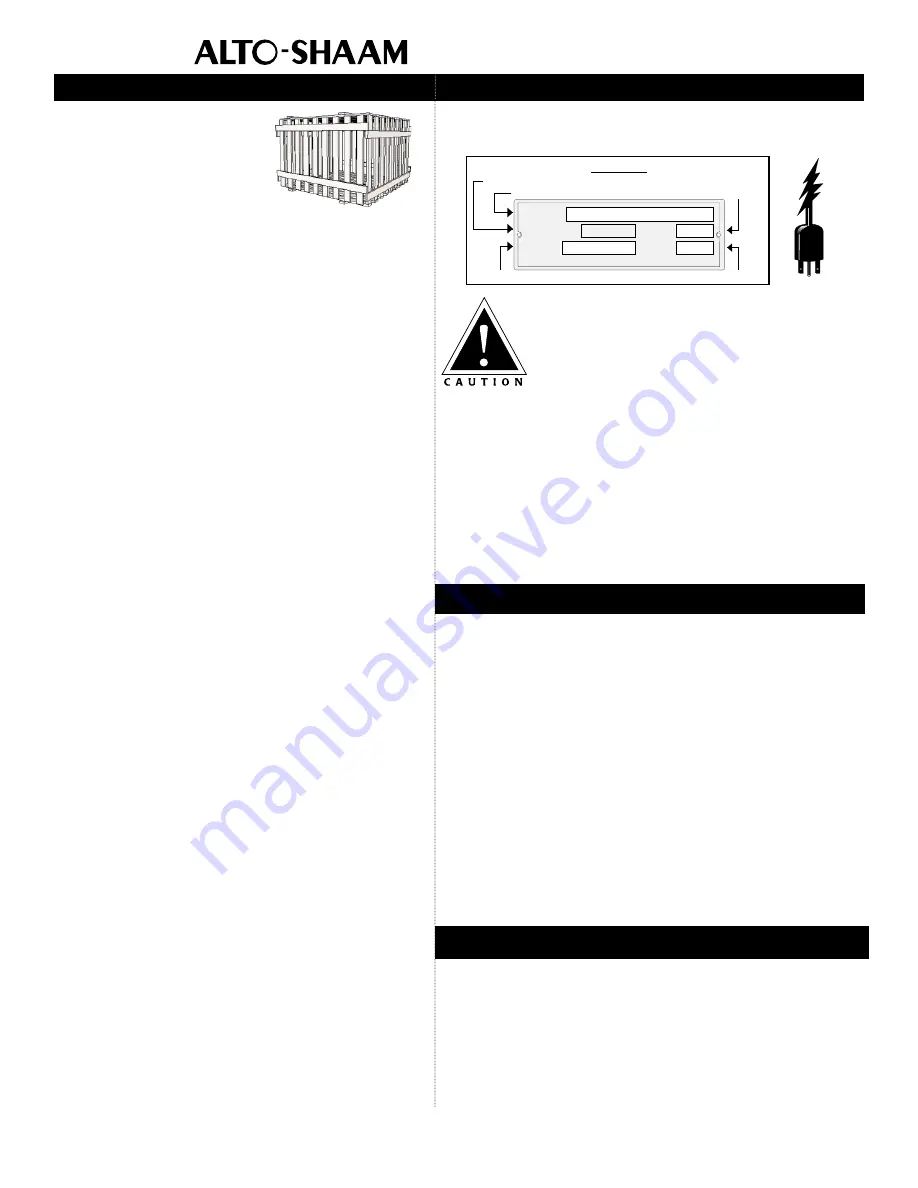

H A R A C T

ENSURE

POWER SOURCE

MATCHES VOLTAGE STAMPED

ON NAMEPLATE OF UNIT

EXAMPLE

S E R I A L N U M B E R A N D WA R R A N T Y C O D E

M A X I M U M R AT E D

WAT TA G E

I D E N T I F I C AT I O N M O D E L N U M B E R

M A X I M U M R AT E D V O LTA G E

M A X I M U M R AT E D F R E Q U E N C Y

MODEL

SERIAL NO.

WATTS

1 PH

VOLTS

xxx-xx

xxxx-xx

xxxx

xx

HZ

xxx

AC

ALTO-SHAAM INC. MILW. WI. PAT. NO. 3521030

W A R M I N G C H A R A C T E R I S T I C S

The cabinet is equipped with a special, low-heat-density,

heating cable. Through the Halo Heat concept, the heating

cable is mounted against the walls of the warming

compartment to provide an evenly applied heat source,

controlled by an electronic thermostat. The design and

operational characteristics of the unit eliminates the need for

a moisture pan or a heat circulating fan. Through even heat

application, the quality of a food product is maintained for

short periods or for longer time periods, up to several hours.

The heated compartment is equipped with an electronic ther-

mostat, pilot light, and digital display to monitor inside air

temperature.

R E F R I G E R A T I O N C H A R A C T E R I S T I C S

The cabinet is equipped with a 1/3 horsepower

compressor, R-404A refrigerant, low pressure safety switch

in the event a refrigerant leak should occur, and a

timer/defrost mechanism. Each cabinet is equipped with

an electronic thermostat and digital display to monitor inside

air temperature.

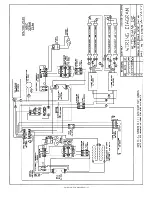

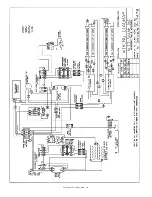

E L E C T R I C A L I N S T A L L A T I O N

An identification tag is permanently mounted on

the cabinet.

A proper receptacle or outlet configuration, as required

for this unit must be installed by a licensed electrician

in accordance with applicable, local electrical codes.

Permanent wiring for this unit must be installed by a

licensed elecrician in accordance with applicable local

electrical codes. Position the merchandiser so that the

power supply cord is easily accessible in case of an

emergency.

®

– M E R C H A N D I S E R S

Summary of Contents for 1000-HCM

Page 14: ...Operation Care Manual 843 13...

Page 15: ...Operation Care Manual 843 14...