C A R E a n d C L E A N I N G

The cleanliness and appearance of this

equipment will contribute considerably to

operating efficiency and savory, appetiz-

ing food. There is an important relation-

ship between cleanliness and food flavor

and aroma. Good equipment that is kept

clean works better and lasts longer.

CLEAN THE HOT & COLD MERCHANDISER

DAILY.

1. Disconnect the merchandiser from its power

source.

2. Remove any left over food products and store in

another case.

3. Remove the wire shelves, side racks and baffle pan.

Clean these items separately with warm water or

commercial detergent. Rinse well with a sanitizing

solution.

4. Remove all loose debris which may clog the drain

in the refrigerated compartment. Clean the interior

walls of the merchandiser with a damp cloth and

any good alkaline or alkaline chlorinated based

commercial detergent or grease solvent at the rec-

ommended strength. Use a plastic scouring pad for

difficult areas. Avoid the use of abrasive cleaning

compounds, chloride based cleaners, or cleaners

containing quaternary salts. Rinse well to remove

all residue and wipe dry.

NOTE: Never use

hydrochloric acid (muriatic acid) on stainless steel.

5. Remove the slide out drain pan underneath the unit,

empty and wash with warm soapy water or commer-

cial detergent.

6. To help maintain the protecive film coating on pol-

ished stainless steel, clean the exterior of the cabi-

net with a cleaner recommended for stainless steel

surfaces. Spray the cleaning agent on a cloth and

wipe with the grain of the stainless steel.

7. Remove the pull-out door gasket and wash in hot

soapy water or in the dishwasher. Always replace

gasket before operating the merchandiser.

8. Clean the glass with a window cleaner.

9. Clean the menu panels with soap or mild detergent

and water. Dry with a clean, damp chamois.

Grease and oil may be removed with naptha or

hexane.

DO NOT USE HOUSEHOLD CLEANERS

CONTAINING AMMONIA.

To avoid scratching,

do not use dry cloths or scouring compounds

.

AT NO TIME SHOULD THE

COMPARTMENTS, OR THE CABINET

EXTERIOR BE STEAMED CLEANED,

WASHED DOWN, FLOODED WITH WATER

OR LIQUID SOLUTION. DO NOT USE

WATER JET TO CLEAN. SEVERE DAMAGE

OR ELECTRICAL HAZARD COULD RESULT,

VOIDING THE WARRANTY.

Always follow appropriate state or local health

(hygiene) regulations regarding all applicable

cleaning and sanitation requirements for equipment.

Operation & Care Manual #843 • 7.

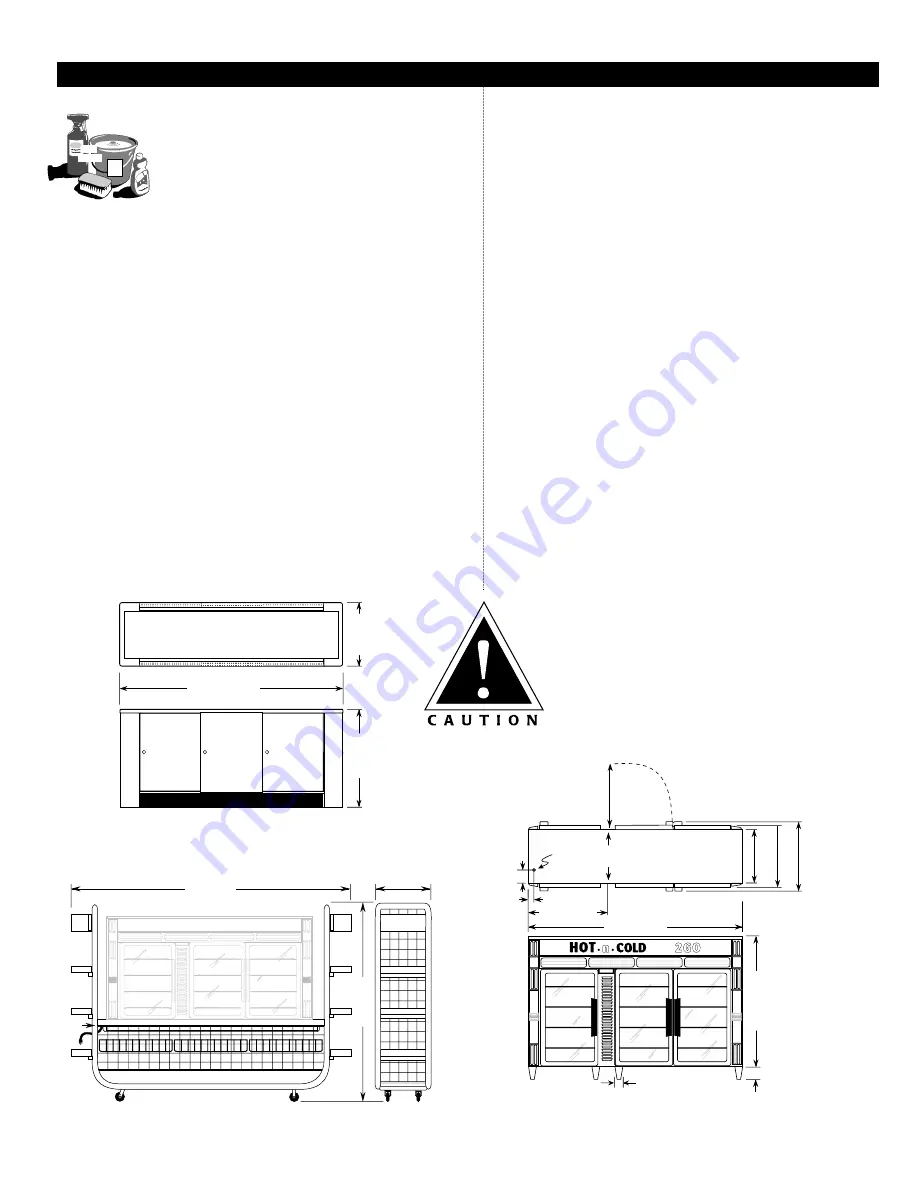

18-1/2"

(470mm)

74-3/8" (1889mm)

VENT

-1/8"

(537mm)

24

"

(610mm)

26-7/8" (683mm)

ALTO-SHAAM

ALTO-SHAAM

44-5/8"

(1133mm)

4-1/2" (114mm)

2" (51mm)

ELEC.

(BOTTOM)

4" (102mm)

2" (51mm)

20-3/4" (527mm)

ALTO-SHAAM

ALTO-SHAAM

Meal Express

ress

Me

85" (2159mm

)

120" (3048mm)

Meal Express

24"

(610mm)

Elec

.

31-13/16"

(808mm)

21"

(532mm)

77-3/16" (1961mm

)

U N - 2 3 7 3 4 R A C K

3 3 0 0 - H C M B A S E

Summary of Contents for 1000-HCM

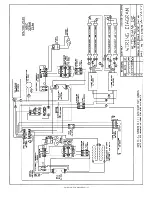

Page 14: ...Operation Care Manual 843 13...

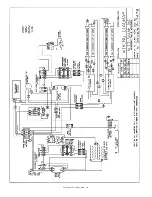

Page 15: ...Operation Care Manual 843 14...