Op e ra tio n a n d C a re Ma n u a l • 8.

O P E R A T I O N

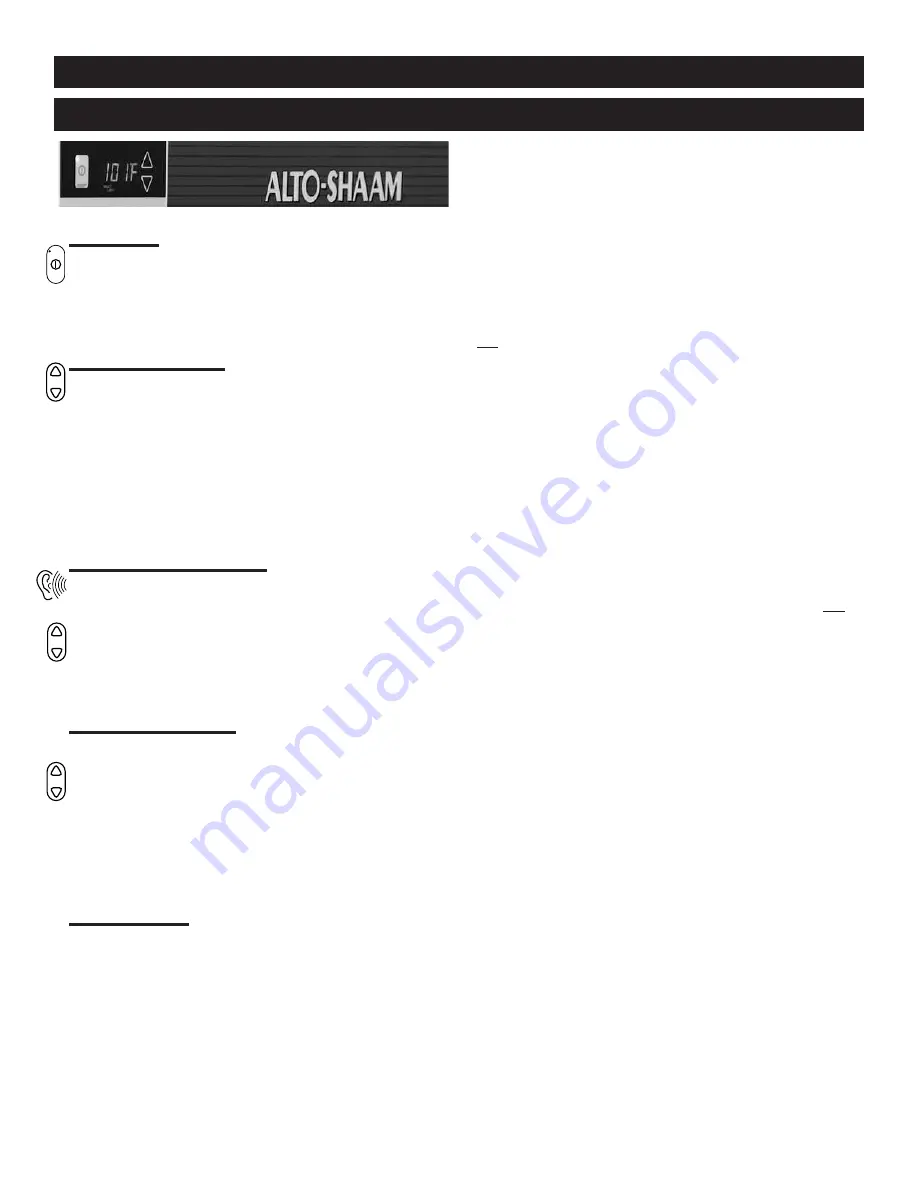

ON/OFF Key

Press the ON/OFF key once and the power indicator

light will illuminate. Press and hold the ON/OFF key

until the LED display turns off (at least three seconds)

and power indicator light goes out.

UP/DOWN Arrow Key

The UP and DOWN arrow keys are used for a variety of

settings when selecting the holding temperature. If an

arrow key is pressed and released, the display will show

the current set temperature for two seconds. If an arrow

key is held (at least eight seconds), the value will change

at a rapid rate. If the arrow key is pressed and released in

rapid succession, the set temperature will change by

increments of one degree

.

ENABLE/DISABLE BEEPER

A beeper sounds when an error code is displayed.

To choose between beeper on and beeper off mode,

the control must be off, then press and hold the DOWN

arrow key until either "ON" or "OFF" is shown in the

LED display. Release arrow key when desired mode

is displayed.

FAHRENHEIT/CELSIUS

With the control off, to choose between Fahrenheit

and Celsius, press and hold the UP arrow key until

either °F or °C is shown in LED display. Release key

when desired setting is displayed.

The control has a four-digit LED display. When the

display is on, it will show current holding tempera-

ture, as well as diagnostic information.

CONTROL LOCK

The warmer controls can be locked so that no changes can

be made to the set temperature.

To lock the display, press and hold the ON/OFF key and

the Up Arrow key at the same time. The lock LED will illu-

minate. When the lock LED is illuminated, additional pro-

gramming will not be functional other than the key

sequence required to unlock the panel.

To unlock the display, press and hold the ON/OFF key and

the Down Arrow key at the same time. The lock LED will

extinguish. The panel keys will resume normal function.

Before Initial Use:

Clean appliance with a clean, damp cloth and mild

soap solution. Glass cleaner or distilled vinegar can

be used on any glass. Clean and install the pans,

shelves and side racks.

1. Preheat at 200°F (93°C) for 30 minutes.

Press the ON key, and set the temperature to

200°F (93°) by using the UP/DOWN arrow keys.

Allow a minimum of 30 minutes preheating time

before loading the holding cabinet with food.

Closing the vents on the inside of the door will

speed the preheating process. The LED heat

indicator light will go “Out” after approximately

30 minutes preheat time, or when the air tempera-

ture inside the unit reaches the temperature set by

the operator. The Set indicator will light up any-

time the temperature is set or reset.

2. Load with hot food only.

The purpose of the holding cabinet is to maintain

hot food at proper serving temperature. Only hot

food should be placed into the cabinet. Before

loading the cabinet with food, use a food ther-

mometer to make certain all products are at an

internal temperature range of 140° to 160°F

(60° to 71°C). Any food product not within the

proper temperature range should be heated before

loading into the holding cabinet.

3. Reset the control to 160°F (71°C).

Check to make certain the cabinet door is securely

closed, and reset to 160°F (71°C) by using the

UP/DOWN keys . THIS WILL NOT NECESSARILY

BE THE FINAL SETTING. The proper temperature

range--or closing or opening the door vents--will

depend on the type and quantity of product.

When holding food for prolonged periods, it is

advisable to periodically check the internal

temperature of each item with a food thermometer

to assure maintenance of the proper temperature

range of 140° to 160°F (60° to 71°C).

°F/°C

Electronic Control