COMbIThERM® ES SERIES

•

ELECTRIC

INSTALLATION MANUAL #MN-28897 •

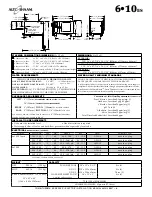

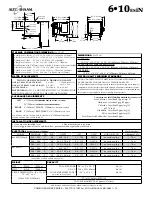

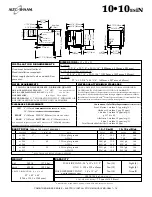

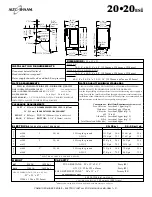

19.

46-3/4"

(1186mm)

44-3/4"

(1136mm)

40-15/16"

(1039mm)

1-13/16"

(46mm)

48"

(1218mm)

45-5/16"

(1151mm)

33-1/2"

(851mm)

2-1/16" (52mm)

Water Drain

(Bottom)

51-15/16"

(1319mm)

2" (50mm)

76-15/16" (1954mm)

8-15/16" (226mm)

7-11/16" (195mm)

46-1/2" (1155mm)

54-3/8" (1381mm)

13-1/16" (331mm)

15-13/16" (401mm)

22-11/16"

(576mm)

11-7/8"

(302mm)

Water Drain

(Back)

Steam

Vents

(Top)

4-1/4"

(106mm)

Treated Water

Intake (Bottom)

Untreated Water

Intake

(Bottom)

Electrical

Connection (Bottom)

6-11/16"

(169mm)

dimensions:

h x w x d

EXtEriOr

:

54-3/8" x 46-3/4" x 48" (1381mm x 1186mm x 1218mm)

EXtEriOr

witH

rEcEssEd

dOOr

:

54-3/8" x 50-3/4" x 48" (1381mm x 1288mm x 1218mm)

interior

:

38-11/16" x 26-1/4" x 32-11/16" (983mm x 667mm x 830mm)

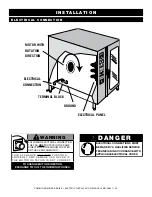

installation requirements

oven must be installed level.

hood installation is required.

Water supply shut-off valve and back-flow preventer.

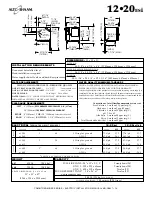

12•20

es

i

capacity

Full-siZe pans: 20" x 12" x 2-1/2"

Twenty-four (24)

gn 1/1: 530 x 325 x 65mm

Twenty-four (24)

gn 2/1: 650 x 530 x 65mm

Twelve (12)

Full-siZe sheeT pans:* 18" x 26" x 1"

Twelve (12)

on

wire

shelves

only

288 lb (131 kg)

MaXiMuM

vOluME

MaXiMuM

: 180 quarts (228 liters)

weight

net

630 lb

(286 kg)

ship

750 lb

(340 kg)

cratE

diMENsiONs

:

(

l

X

w

X

H

)

Est

53" x 53" x 87"

(1346 x 1346 x 2210mm)

electrical

(

d e d i c a t e d

c i r c u i t

r e q u i r e d

)

12•20

e s

i

12•20

e s

i/sk

vOltagE

PHasE

cyclE

/

Hz

awg

aMPs

kW

amps

kW

at 208

3

60

3 wire plus ground

75.6/ph 27.2 77.0/ph 27.7

at 240

awg 2

87.0/ph 36.1 88.2/ph 36.6

at 380

3

50

4 wire plus ground

41.4/ph 27.2 42.1/ph 27.7

at 415

awg 6

50.0/ph 35.7 51.0/ph 36.6

at 440

3*

60

3 wire plus ground

36.0/ph 27.2 36.4/ph 27.7

at 480

awg 6

43.5/ph 36.1 44.0/ph 36.6

*

ElEctrical

sErvicE

cHargE

aPPliEs

208-240

380-415

440-480

water requirements

water quality minimum standards

TWO (2) COLD WATER INLETS - DRINKING QUALITY

ONE (1) TREATED WATER INLET: 3/4" npT*

ONE (1) UNTREATED WATER INLET: 3/4" npT*

LINE PRESSURE: 30 to 90 psi 2.8 to 6.2 bar

WATER DRAIN:

1-1/2" connecTion wiTh a 2" MiniMuM air gap

insTalled as close To The oVen as possiBle

using a waTer supply noT MeeTing alTo-shaaM’s MiniMuM

waTer QualiTy sTandards will Void This warranTy.

it is the responsibility of the purchaser to ensure that incoming water supply is

compliant with the specifi cations listed through adequate treatment measures.

installation of the combiguard

TM

water Filtration system is recommended, but

this system may not address all water quality issues present.

clearance requirements

Contaminant

Free chlorine

hardness

chloride

ph

alkalinity

silica

Total dissolved solids (tds)

Inlet Water Requirements (

untreated water

)

less than 0.1 ppm (mg/l)

less than 3 gpg (52 ppm)

less than 30 ppm (mg/l)

7.0 to 8.5

less than 50 ppm (mg/l)

less than 12 ppm (mg/l)

less than 60 ppm

LEFT 6" (152mm)

RECOMMENDED SERVICE ACCESS: 18" (457mm)

20" (508mm)

FROM HEAT PRODUCING EQUIPMENT

RIGHT 4" (102mm) TOP: 20" (508mm)

For air MoVeMenT

BACK 4" (102mm) BOTTOM: 5-1/8" (130mm)

For legs

* can manifold off of

one 3/4" line.