# 8 2 8 O p e r a t i o n a n d C a r e M a n u a l • 13.

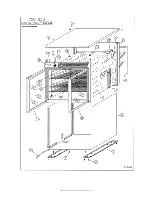

S E R V I C E

8 / 2 7 / 0 2

Quantity

A/S Part

Description

per Unit

Number

1. TOP

1

11559

2. TOP MOUNTING SCREWS

2

SC-2425

3. CASTER BRACKET

2

4974

4. CASTER BRACKET MOUNTING SCREWS

8

SC-2425

5. CORD, 125V

1

CD-33367

CORD, 230V

1

CD-3922

BUSHING

1

BU-3011

6. CASING, BOTTOM

1

14523

CASING, RIGHT-HAND

1

14332

CASING, LEFT-HAND

1

14333

7. CASING MOUNTING SCREWS

6

SC-2425

8. INSULATION: 25” x 120”

(635mm x 3048mm)

1

IN-22364

9. CABLE CONNECTION HARDWARE

10. HEATING CABLE: Length 144’ (43891mm)

1

CB-3045

11. THERMOSTAT

1

TT-3057

— THERMOSTAT KNOB, Fahrenheit

1

KN-3469

— THERMOSTAT KNOB, Celsius

1

KN-3474

12. TEMPERATURE GAUGE

1

GU-3273

13. HEAT INDICATOR LIGHT, 125V

1

LI-3493

HEAT INDICATOR LIGHT, 230V

1

LI-3923

14. LIGHT SWITCH

1

SW-3887

15. BULB, 125V

2

LP-3480

BULB, 230V

2

LP-3606

16. BULB SOCKET, 125V

2

RP-3952

BULB SOCKET, 230V

2

RP-3955

17. GLASS DOOR, Left-hand

1

4972

18. GLASS DOOR, Right-hand

1

4973

EACH DOOR INCLUDES:

— TOP DOOR HINGE

1

HG-2892

— BOTTOM DOOR HINGE

1

HG-23952

— TOP HINGE PIVOT PIN

1

PI-2894

— BOTTOM HINGE PIVOT PIN

1

PI-23953

— HANDLE

1

HD-2910

— HANDLE MOUNTING SCREWS

2

SC-2911

— DOOR GASKET: Length 6.3’ (1920mm) 1

GS-2891

19. GLASS, BACK (REAR)

1

4971

20. DOOR LATCH

2

LT-23187

21. SIDE RACK, LEFT-HAND

1

SR-2849

SIDE RACK, RIGHT-HAND

1

SR-2850

22. SHELF

3

SH-2851

23. BIMET THERMOSTAT, 230V

ONLY

1

TT-3859

24. FILTER (LINE), 230V

1

FI-33225

FILTER BRACKET

1

13001

25. FUSEHOLDER

1

FU-3884

FUSE

1

FU-3883

SERVICE VIEW • following pages

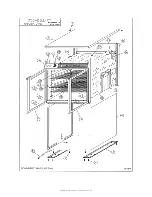

8 / 2 7 / 0 2

Quantity

A/S Part

Description

per Unit

Number

1. TOP

1

11559

2. TOP MOUNTING SCREWS

2

SC-2425

3. CASTER BRACKET

2

4974

4. CASTER BRACKET MOUNTING SCREWS

8

SC-2425

5. CORD, 125V

1

CD-33367

CORD, 230V

1

CD-3922

BUSHING

1

BU-3011

6. CASING, BOTTOM

1

14523

CASING, RIGHT HAND

1

14332

CASING, LEFT HAND

1

14333

7. CASING MOUNTING SCREWS

6

SC-2425

8. INSULATION: 25” x 120”

(635mm x 3048mm)

1

IN-22364

9. CABLE CONNECTION HARDWARE

10. HEATING CABLE: Length 144’ (43891mm)

1

CB-3045

11. THERMOSTAT

1

TT-3057

— THERMOSTAT KNOB, Fahrenheit

1

KN-3469

— THERMOSTAT KNOB, Celsius

1

KN-3474

12. TEMPERATURE GAUGE

1

GU-3273

13. HEAT INDICATOR LIGHT, 125V

1

LI-3493

HEAT INDICATOR LIGHT, 230V

1

LI-3923

14. LIGHT SWITCH

1

SW-3887

15. BULB, 125V

2

LP-3480

BULB, 230V

2

LP-3606

16. BULB SOCKET, 125V

2

RP-3952

BULB SOCKET, 230V

2

RP-3955

17. GLASS DOOR, Left-hand

2

4972

18. GLASS DOOR, Right-hand

2

4973

EACH DOOR INCLUDES:

— TOP DOOR HINGE

1

HG-2892

— BOTTOM DOOR HINGE

1

HG-23952

— TOP HINGE PIVOT PIN

1

PI-2894

— BOTTOM HINGE PIVOT PIN

1

PI-23953

— HANDLE

1

HD-2910

— HANDLE MOUNTING SCREWS

2

SC-2911

— DOOR GASKET: Length 6.3’ (1920mm)

1

GS-2891

19. DOOR LATCH

4

LT-23187

20. SIDE RACK

2

SR-2213

21. SHELF

3

SH-2114

22. BIMET THERMOSTAT, 230V only

1

TT-3859

23. FILTER (LINE), 230V

1

FI-33225

FILTER BRACKET

1

13001

24. FUSEHOLDER

1

FU-3884

FUSE

1

FU-3883

SERVICE VIEW • following pages

750-GDU - REACH-IN

750-GDU/PT - PASS-THRU