HSM

INSTALLATION

/

OPERATION

/

SERVICE MANUAL

PG

. 11

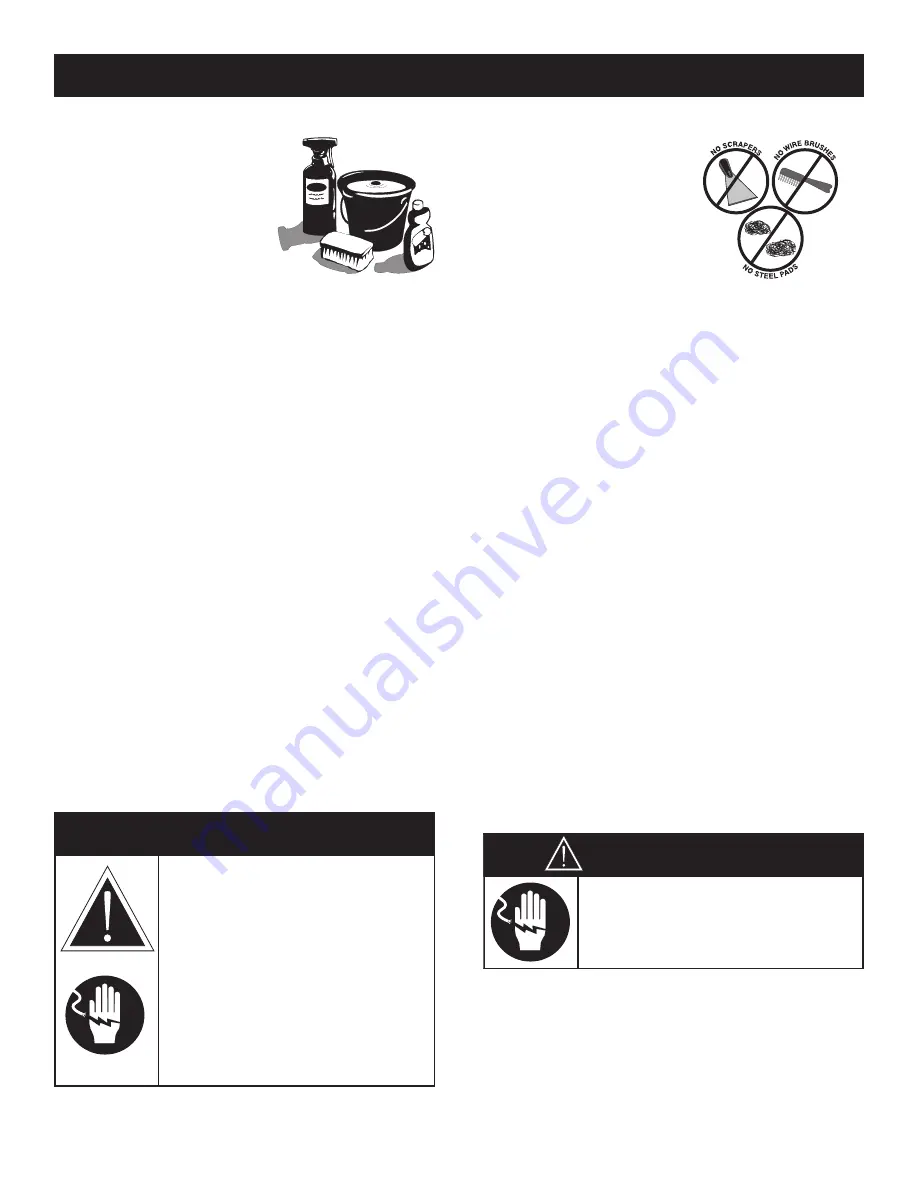

The cleanliness and

appearance of this unit will

contribute considerably to

operating efficiency and

savory, appetizing food.

Good equipment that is kept

clean works better and lasts

longer.

CLEAN THE UNIT

THOROUGHLY

AFTER EACH USE

1.

Turn lights and adjustable thermostat(s) to the

"OFF" position. Disconnect unit from power

source, and let cool.

2.

Remove, cover or wrap, and store food product

under refrigeration.

3.

Do not clean the glass when hot.

The glass should be cleaned regularly with

fresh warm water, a mild detergent, and a

clean, non-abrasive cloth. Glass cleaner

can be used.

4.

Clean other interior components with a damp

cloth or sponge and any good commercial

detergent at the recommended strength.

5.

Spray heavily soiled areas with a water

soluble degreaser and let stand for 10 minutes,

then remove soil with a plastic scouring pad.

NOTE:

Avoid the use of

abrasive cleaning

compounds,

chloride based

cleaners, or

cleaners

containing

quaternary salts.

Never

use hydrochloric acid

(muriatic acid) on stainless steel.

6.

Clean control panel, vents, handles, and gaskets

thoroughly since these areas harbor food debris.

7.

Rinse surfaces by wiping with sponge and clean

warm water.

8.

Remove excess water with sponge and wipe dry

with a clean cloth or air dry.

9.

Interior can be wiped with a sanitizing solution

after cleaning and rinsing. This solution must

be approved for use on food contact surfaces.

10.

To help maintain the protective film coating on

any polished stainless steel, clean the exterior

of the cabinet with a cleaner recommended for

stainless steel surfaces. Spray the cleaning

agent on a clean cloth and wipe with the grain

of the stainless steel.

Always follow appropriate state or local health

(hygiene) regulations regarding all applicable

cleaning and sanitation requirements for foodservice

equipment.

C A R E A N D C L E A N I N G

D A N G E R

AT NO TIME SHOULD THE INTERIOR

OR EXTERIOR BE STEAM CLEANED,

HOSED DOWN, OR FLOODED WITH

WATER OR LIQUID SOLUTION OF

ANY KIND. DO NOT USE WATER JET

TO CLEAN.

SEVERE DAMAGE OR

ELECTRICAL HAZARD

COULD RESULT.

WARRANTY BECOMES VOID IF

APPLIANCE IS FLOODED

D A N G E R

DISCONNECT UNIT FROM

POWER SOURCE BEFORE

CLEANING OR SERVICING.