PG

. 12

HSM

INSTALLATION

/

OPERATION

/

SERVICE MANUAL

S A N I T A T I O N

Food flavor and aroma are usually so closely

related that it is difficult, if not impossible, to

separate them. There is also an important,

inseparable relationship between cleanliness and

food flavor. Cleanliness, top operating efficiency,

and appearance of equipment contribute

considerably to savory, appetizing foods.

Good equipment that is kept clean, works

better and lasts longer.

Most food imparts its own particular aroma and

many foods also absorb existing odors.

Unfortunately, during this absorption, there is no

distinction between GOOD and BAD odors. The

majority of objectionable flavors and odors

troubling food service operations are caused by

bacteria growth. Sourness, rancidity, mustiness,

stale or other OFF flavors are usually the result of

germ activity.

The easiest way to insure full, natural food flavor is

through comprehensive cleanliness. This means

good control of both visible soil (dirt) and invisible

soil (germs). A thorough approach to sanitation

will provide essential cleanliness. It will assure an

attractive appearance of equipment, along with

maximum efficiency and utility. More importantly,

a good sanitation program provides one of the key

elements in the prevention of food-borne illnesses.

A controlled holding environment for prepared

foods is just one of the important factors involved

in the prevention of food-borne illnesses.

Temperature monitoring and control during

receiving, storage, preparation, and the service of

foods are of equal importance.

The most accurate method of measuring safe

temperatures of both hot and cold foods is by

internal product temperature. A quality

thermometer is an effective tool for this purpose,

and should be routinely used on all products that

require holding at a specific temperature.

A comprehensive sanitation program should focus

on the training of staff in basic sanitation

procedures. This includes personal hygiene,

proper handling of raw foods, cooking to a safe

internal product temperature, and the routine

monitoring of internal temperatures from receiving

through service.

Most food-borne illnesses can be prevented

through proper temperature control and a

comprehensive program of sanitation. Both these

factors are important to build quality service as the

foundation of customer satisfaction. Safe food

handling practices to prevent food-borne illness is

of critical importance to the health and safety of

your customers.

HACCP, an acronym for Hazard Analysis (at)

Critical Control Points, is a quality control program

of operating procedures to assure food integrity,

quality, and safety. Taking steps necessary to

augment food safety practices are both cost

effective and relatively simple. While HACCP

guidelines go far beyond the scope of this manual,

additional information is available by contacting:

CENTER FOR FOOD SAFETY AND APPLIED

NUTRITION FOOD AND DRUG ADMINISTRATION

1-888-SAFEFOOD

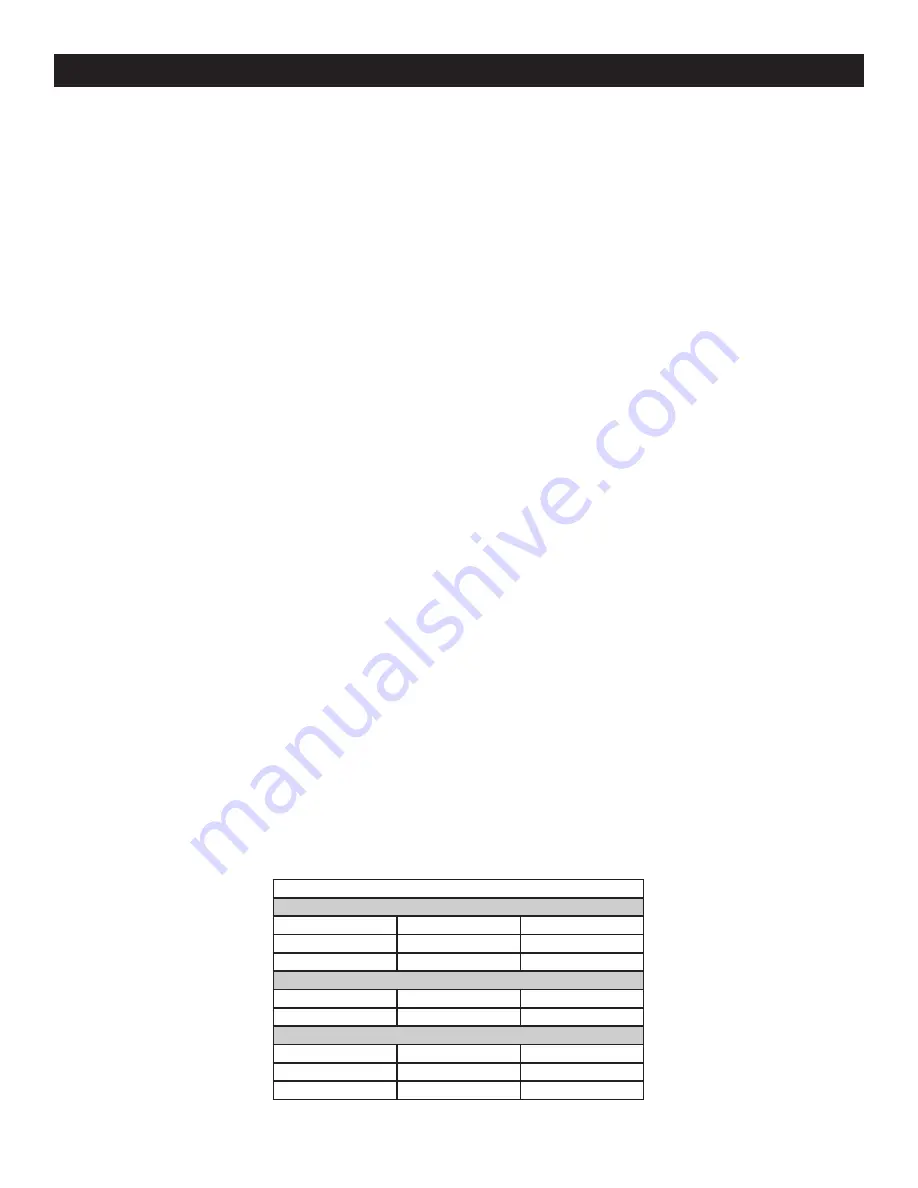

INTERNAL FOOD PRODUCT TEMPERATURES

HOT FOODS

DANGER ZONE

40° TO 140°F

(4° TO 60°C)

CRITICAL ZONE

70° TO 120°F

(21° TO 49°C)

SAFE ZONE

140° TO 165°F

(60° TO 74°C)

COLD FOODS

DANGER ZONE

ABOVE 40°F

(ABOVE 4°C)

SAFE ZONE

36°F TO 40°F

(2°C TO 4°C)

FROZEN FOODS

DANGER ZONE

ABOVE 32°F

(ABOVE 0°C)

CRITICAL ZONE

0° TO 32°F

(-18° TO 0°C)

SAFE ZONE

0°F or below

(-18°C or below)