31

SSB 400 W

SSE 400 W

SSB 480 W

SSE 480 W

Use for the intended purpose

All automatic cleaning

machines are exclusively

intended for the wet cleaning of

water-resistant floor coverings in

building interiors.

Any use going beyond that is

deemed not to be in line with

the intended purpose. The

manufacturer does not accept

any liability for any resultant

damage; the risk in such cases

is borne by the user only.

Use for the intended purpose

also includes adherence to the

operating, servicing and

maintenance instructions

prescribed by the manufacturer.

The relevant accident

prevention regulations and

other generally recognised

safety and industrial health

rules are to be observed.

Changes made to the

automatic machines by the

users themselves rule out the

liability of the manufacturer for

any resultant damage.

Floor coverings are to be

checked with regard to the

suitability of this cleaning

method before the use of the

machine!

Note the surface pressure in

the case of point-elastic floors,

e.g. in gymnasiums!

The manufacturer accepts no

liability for damage to the

machine and the floor covering

to be cleaned which is caused by

the use of the wrong brushes

and cleaning agents.

Product liability

The user’s attention is expressly

drawn to the fact that the

automatic machines may be

used exclusively for the purpose

for which they are intended.

Should the machines not be

used for the intended purpose,

responsibility for this is to be

borne solely by the user. The

manufacturer is thus relieved of

all responsibility.

Hazards

When the machine is at a

standstill, the brush motor must

be switched off immediately so

that no damage to the floor

covering occurs.

Travel carefully over thresholds

and landings, as the wheels

and/or the suction lips can be

damaged. Ensure that the

brush unit and the suction

nozzle are raised.

For transporting in lifts, the

currently valid user notes and

safety regulations - especially

with regard to the carrying

capacity - are to be observed.

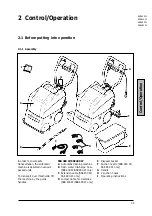

Workstation

The workstation is on the control

panel at the back of the

automatic machine.

Authorised maintenance

personnel

The automatic cleaning machine

may only be serviced and

repaired by persons having

specialist and statutory

authorisations.

Cleaning agents

When using of cleaning and

care agents, the manufacturer’s

hazard warnings are to be

noted; wear protective goggles

and protective clothing if

necessary.

Use only low-foam, non-

flammable cleaning agents

which do not contain

substances which are a general

health hazard.