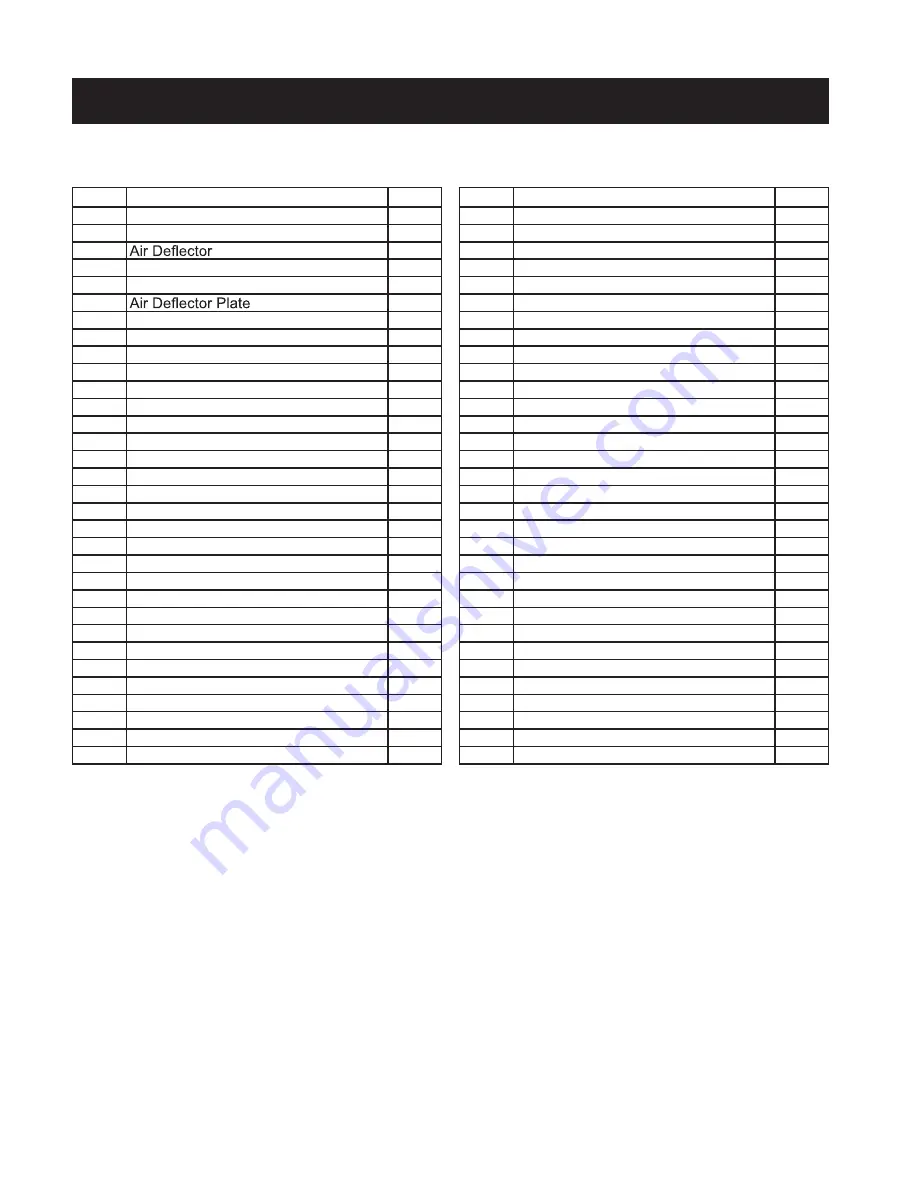

Part

Description

Qty

1

Cap Screw (M5x.80x20mm)

6

2

Spring Gasket

6

3

1

4

Cylinder Cap

1

5

Sealing Gasket

1

6

1

7

O-Ring

1

8

O-Ring

1

9

Head Valve Spring

1

10

Head Valve

1

11

O-Ring

1

12

O-Ring

1

13

O-Ring

1

14

Cylinder Cap Sealing Ring

1

15

Collar

1

16

O-Ring

1

17

Cylinder

1

18

O-Ring

1

19

O-Ring

1

20

Piston Assembly

1

21

Bumper

1

22

Housing

1

23

Sealing Washer

1

24

Safety Spring

1

25

Push Stem

1

26

Safety

1

27

Guide Sleeve

1

28

Cap Screw (M4x.70x8mm)

1

29

Rectangle Sealing Ring

1

30

Valve Seat

1

31

O-Ring

2

32

Valve Stem

1

Part

Description

Qty

33

O-Ring

1

34

Valve Sleeve

1

35

Trigger Spring

1

36

Trigger

1

37

Position Pin

1

38

Safety Plate

1

39

Pin

1

40

Drive Guide

1

41

Fixed Cover

1

42

Movable Plate

1

43

Pin

1

44

Quick Release Lever

1

45

Quick Release Spring

1

46

Pin

1

47

Cap Screw (M4x.70x8mm)

4

48

Locking Sleeve

3

49

Insert Bar

1

50

Fixed Magazine

1

51

Position Plate

1

52

Sliding Magazine

1

53

Pin

1

54

Pusher

1

55

Pusher Stem

2

56

Pusher Spring

2

57

Pin

1

58

Latch

1

59

Latch Spring

1

60

Rubber

1

61

O-Ring

1

62

End Cap

1

63

AIr Inlet Plug

1

64

Air Inlet Plug Cover

1

PARTS LIST

Please refer to the assembly diagram on page 8.

7

Summary of Contents for 18 GA.BRAD

Page 8: ...ASSEMBLY DIAGRAM 8...