7

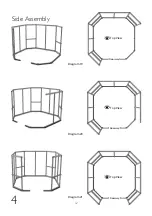

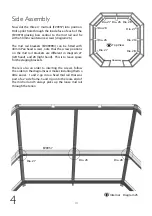

Side Assembly

4

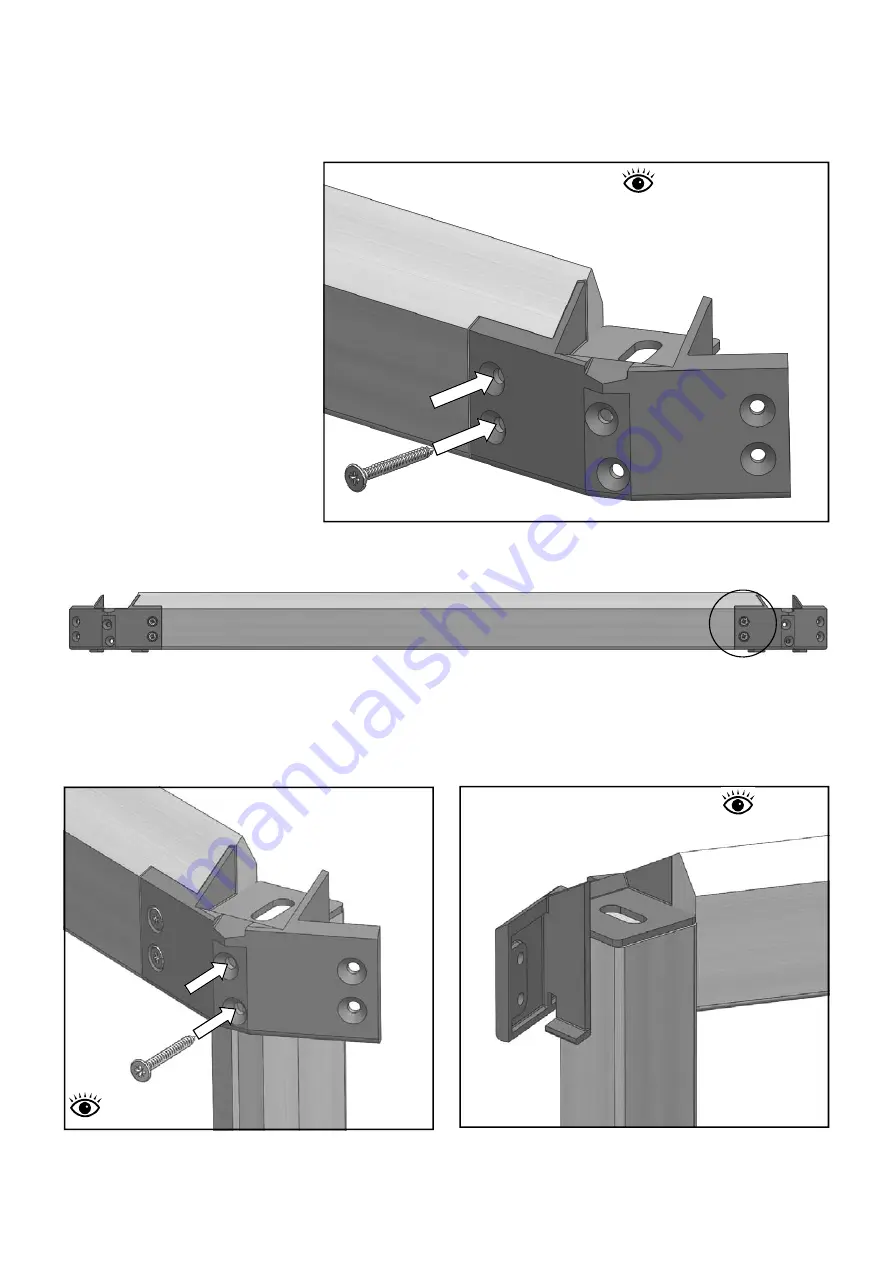

Start by attaching the cast

eaves brackets (EV1000M) to

four eaves rails (EV0953).

First of all drill pilot holes

through the eaves bracket

into the end of the eaves

bar. Be careful not to drill all

the way through the rail!

Once the bracket is firmly in

position fix with the 40mm

countersunk (CSK) screws

(diagrams 5 and 6).

Diagram 6

Diagram 7

Diagram 8

X 4

Diagram 5

Dia. 6

40mm Screw

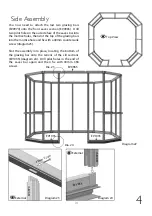

Once you have attached all the cast eaves brackets you can fix two standard side glazing bars

(EV0969) to each of the prepared eaves rails. Make sure the glazing bar is tight into the bracket

(diagrams 7 and 8), drill pilot holes and fix using 50mm CSK screws. Don’t over tighten these screws

as it may make it difficult to glaze later in the build.

50

mm

Sc

rew

EV1000M

EV095

3

EV0953

EV0

953

EV1000M

EV0969

EV0969

EV0953

EV1000M

External

Internal

External

Summary of Contents for Evolution octagonal

Page 1: ...1 04 19...