23

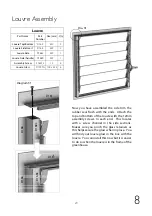

Louvre Assembly

8

Louvre

Part Name

Part

Number

Size (mm) Qty

Louvre Top/Bottom

D165 612 2

Louvre Side Insert

D166 552 2

Louvre Side

D168L 552 1

Louvre Side (handle)

D168R 552 1

Assembly Screw

FS6013 12 4

Louvre Glass

D729TG 100 x 525

6

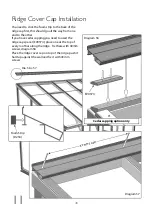

Now you have assembled the side trim the

rubber seal flush with the ends. Attach the

top and bottom of the louvre with the 12mm

assembly screws. In each end. This locates

with a screw channel in the side sections.

Makes sure you pinch the glass retainers as

this helps secure the glass when in place. You

will find your louvre glass in the box with the

louvre. You can install this now but it is easier

to do so when the louvre is in the frame of the

greenhouse.

D165

D166

D168L

D166

D168L

D165

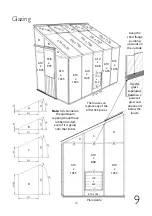

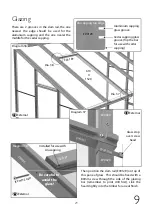

Diagram 31

Dia. 31