Installation Instructions

4 / 11 / 2022 / Rev 1

1170 N Red Gum St, Anaheim, CA 92806

© ALUZ All Rights Reserved. ALUZ reserves the right to make changes or withdraw specifi cations without prior notice.

info@aluz.lighting

aluz.lighting

866.ALUZ.LTG | 714.535.7900

A8 Series

|

LED Tape

ZIZA

Standard

(A8-ZIZA-STN)

Page 11 of 12

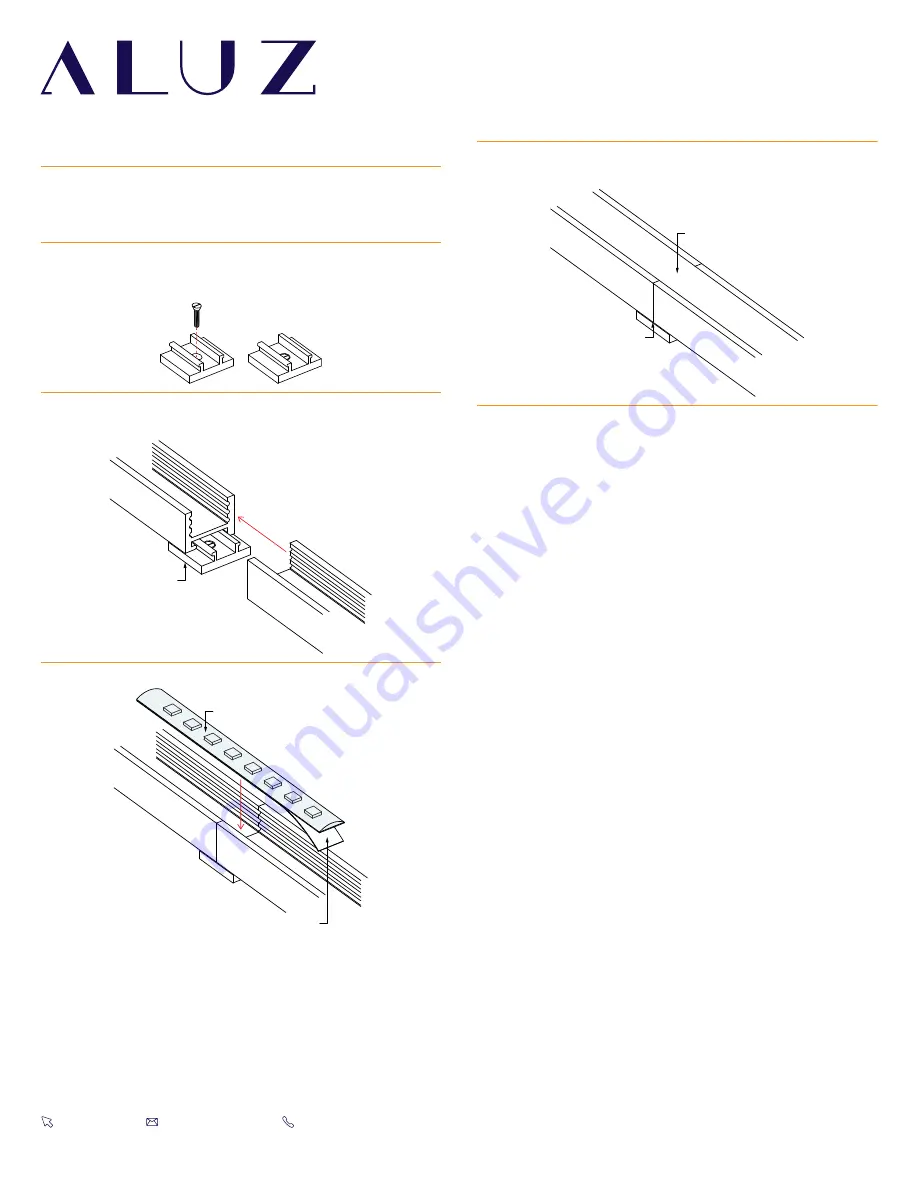

Mounting Fixture (Wet Location

Unassembled Mounting Clips)

MC

Remove adhesive backing

Install lightstrip into extrusions

Lens overlapping

Two extrusions meet

1

Measure area where luminaire will be installed. Use a laser line to create

a reference line along installation area, ensuring consistent alignment of

mounting clips. Mark location where each mounting clip will be installed

along reference line.

3

Lay mounting clips along reference line and pre-drill using an appropriate

drill bit for surface and screw size. Recommendation: 8/32 x 1” screw.

Note:

Allow 0.25” clearance for lateral expansion of assembled mounting

clips.Only install mounting clips on flat, even surfaces.

2

Mark location where mounting clips will be installed.

Note:

The number of required mounting clips differs for dry and wet location

products. Verify number of mounting clips is appropriate for installation

environment before installing. Do not install luminaires with inadequate

number of mounting clips.

4

Screw mounting clips to surface, then snap extrusions into mounting clips.

Note:

Ensure extrusions are aligned. Misalignment will prevent lens from

snapping in.

5

Screw mounting clips to surface, then snap luminaires into mounting clips.

7

Install lens int o extrusion, overlapping where two extrusions meet. Plan

your cuts so that the lens will always overlap where two extrusions meet.

Overlapping lenses helps keep extrusions aligned and prevents light leaks.

8

Perform a continuity test before connecting luminaire to power source.

6

If applicable, connect disconnects between luminaires or solder connectors

using the steps from Application Guidelines.