Installation Instructions

4 / 11 / 2022 / Rev 1

1170 N Red Gum St, Anaheim, CA 92806

© ALUZ All Rights Reserved. ALUZ reserves the right to make changes or withdraw specifi cations without prior notice.

info@aluz.lighting

aluz.lighting

866.ALUZ.LTG | 714.535.7900

A8 Series

|

LED Tape

ZIZA

Standard

(A8-ZIZA-STN)

Page 5 of 12

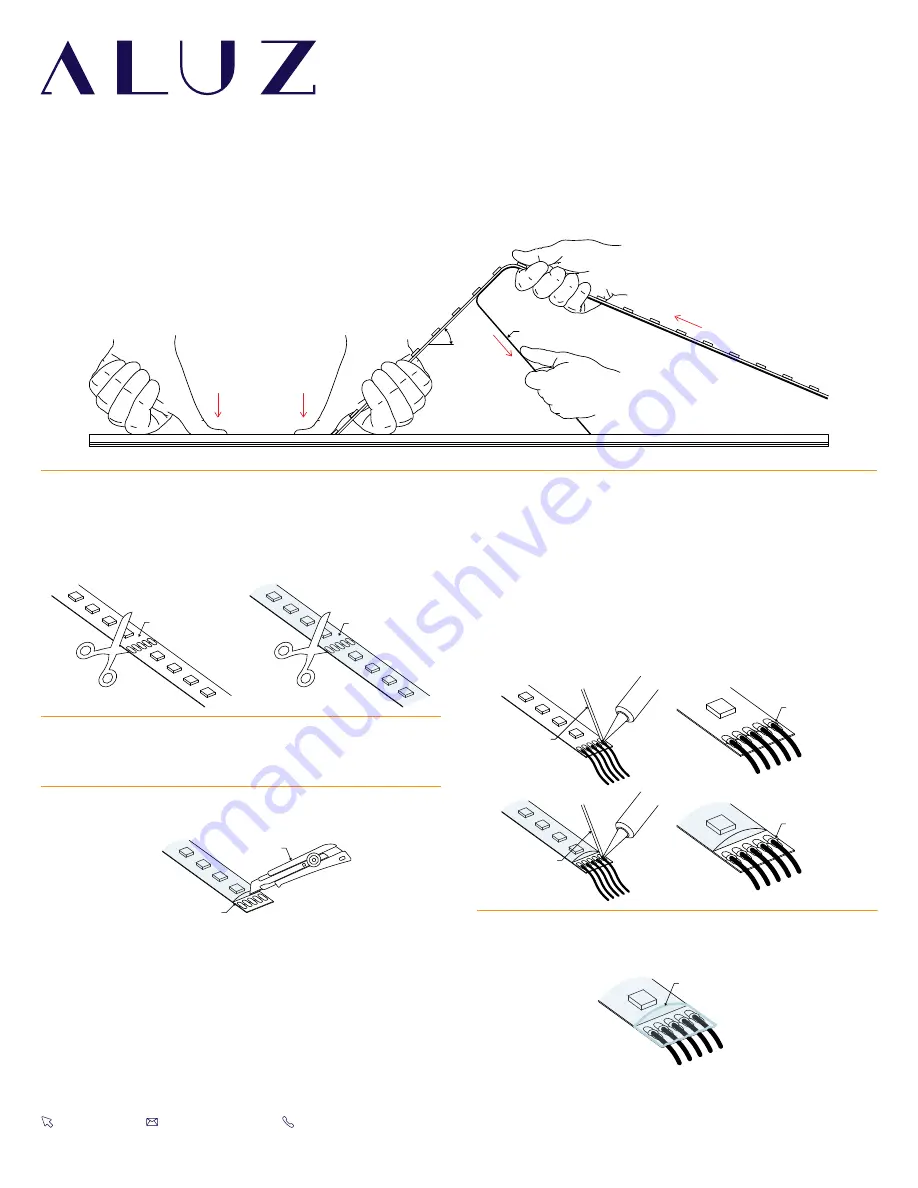

Application Guidelines

45°

ANOTHER PERSON UNREELS LIGHTSTRIP FROM SPOOL, HOLDING AT A 45° ANGLE.

FEED FROM WIRE PULLER STAND

INSTALLERS MUST WEAR GLOVES TO PROTECT LEDS

ONE PERSON APPLIES PRESSURE TO LIGHTSTRIP, SECURING IT TO EXTRUSION

APPLY PRESSURE

TO LIGHTSTRIP,

ENSURING ADHERENCE

TO EXTRUSION

REMOVE ADHESIVE BACKING

LED LIGHTSTRIP

• Extrusions are shipped to exact length of specifi ed measurements.

• Due to cut increment restrictions (4”,+/- 0.125” Tolerance), the lightstrip

is shipped to the closest measurement ordered. The lightstrip must be

centered in the extrusion.

• Remove adhesive backing completely to allow heat transfer tape to

make contact with the aluminum extrusion.

NOTE

• Follow the below diagrams and steps if applicable to your installation.

• LED lightstrip and modules require a team effort to ensure a secure

and correct installation.

• Use a wire puller stand to prevent tangles, twists, and snags.

• For Mud-In applications, start lightstrip from power source side and

allow up to 2” of excess lightstrip to exit through end cap.

APPLICATION GUIDELINES

REMOVE ENCAPSULATION

FROM SOLDER PADS

MAT KNIFE

CUT TO SIZE

CUT TO SIZE

WELLER

0.50”

SOLDER WIRE

SOLDER COVERING

WIRE AND PADS

WELLER

0.50”

SOLDER WIRE

SOLDER COVERING

WIRE AND PADS

COVER CONNECTIONS

WITH SILICONE

SOLDERING GUIDE

1

Cut lightstrip to desired length. Include both sets of solder pads by

cutting to the left or right of designated markings, allowing more

space for soldering.

2

Prepare wires by stripping 1/8” from the end of each wire, then tin

the tips of the wire with solder. Apply heat to stripped portion of

wire, then add a small amount of solder until stripped portion of

wire is fully covered in solder.

3

If applicable, use a mat knife to remove encapsulation from

the section of lightstrip with solder pads. If lightstrip is not

encapsulated, skip this step.

5

If applicable, apply silicone over soldered connections. All

connections must be completely covered with silicone to create

weatherproof seal. Only use outdoor rated silicone. If lightstrip is

not encapsulated, skip this step.

Note:

Appearance of lightstrip may differ from example shown.

Refer to wiring diagrams before soldering any wires.

4

Solder lead wires to solder pads on the end of lightstrip.

• Solder the Black wire to the pad marked “+24V”.

• Solder the Green wire to the pad marked “G”.

• Solder the Red wire to the pad marked “R”.

• Solder the Blue wire to the pad marked “B”.

• Solder the White wire to the pad marked “W”.

Note:

Solder iron not to exceed 720°F. Heat joint with tip of iron.

Heat both the solder pad and the wire. Add a small drop of solder

on the tip of solder iron to transfer the heat to joint quickly; it

should melt and flow smoothly, covering the wire and pad.

Remove iron once enough solder has been added to the

components. Allow 5 seconds for the joint to cool.