Supervisor 3500 Installation Instructions

PUD3673R1-1

For assistance: support@alvaradomfg.com +1 (909) 591-8431

Page 19

The included crossover cable interconnects communication signals

and low-voltage 24VDC between the master and slave cabinets.

The default length of the crossover cable included with the SU3500

is 8'. Optional crossover cable lengths of 20' and 40' are available.

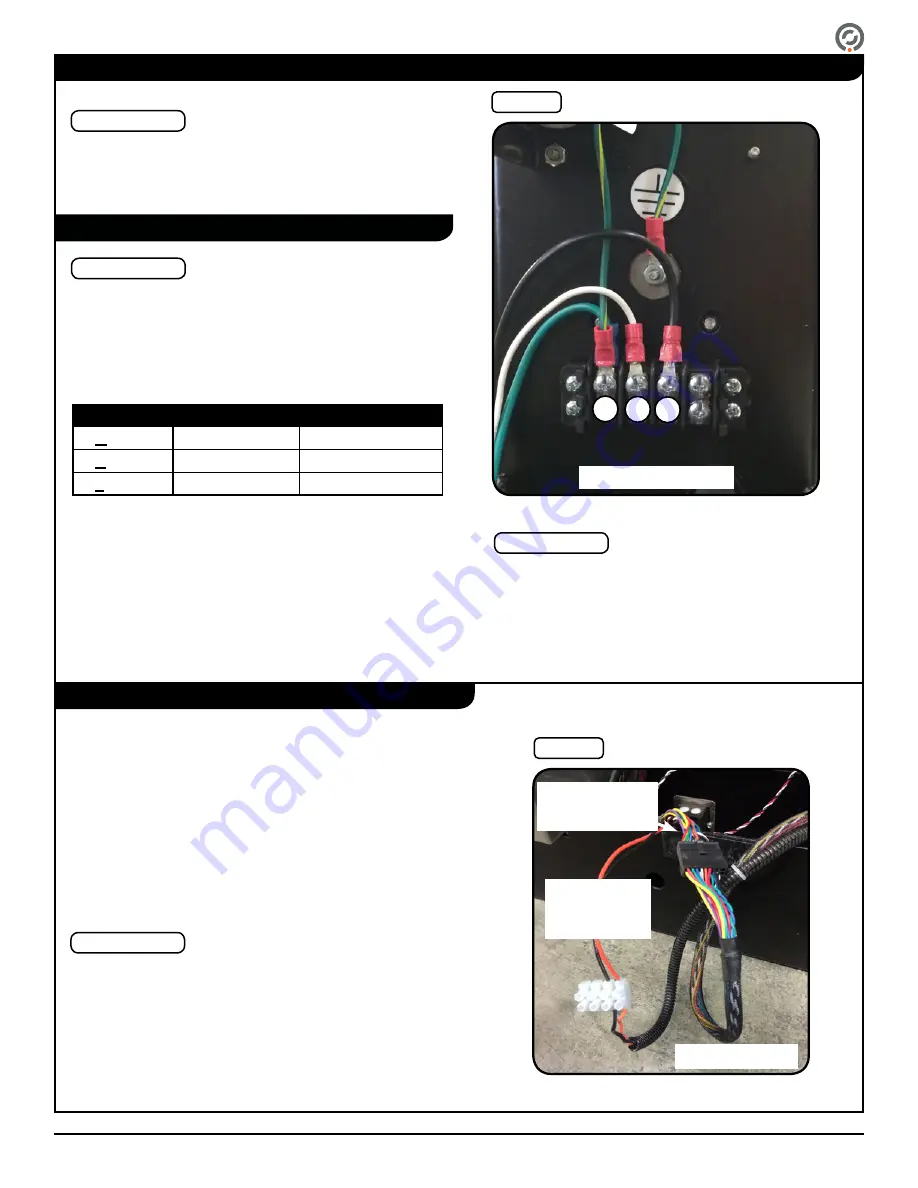

1. Locate the low-voltage terminal block tucked in bottom of the

center base in the master cabinet [Figure 18].

2. Insert the 24VDC positive wire (orange) and the negative wire

(black) into the terminal block, matching the colors with the

other side and tighten [Figure 18].

3. Connect the data connector from the crossover cable to the

data connector in the master cabinet [Figure 18].

4.

Repeat Steps 1 – 3 for the slave cabinet.

Wiring Instructions

IMPORTANT

110VAC and 220VAC primary power (unless ordered otherwise)

must be hard wired in place. It is strongly recommended that a

licensed electrician perform this procedure in accordance with

all applicable local codes.

The primary wiring lines for 110VAC and 220VAC consist of the

following:

Terminal

110V

220V

G

round

Green

Green/Yellow

N

eutral

White

Blue

L

ine

Black

Brown

1. Locate the pre-installed power terminal block and attached

wiring (located inside the leg on master / center cabinets)

[Figure 17].

2. Attach each power wire to the power terminal block with

the corresponding color exiting on the other side.

3. Using a Phillips-head screwdriver, tighten each terminal

block connection.

Primary Power

NOTE

Crossover Cable

Fig. 17

Power Terminal Block

Fig. 18

Crossover Cable & Low Voltage

The orientation of the pre-installed terminal block may

differ from what is shown in [Figure 17]. On some

installations, the terminal block is rotated 90 degrees.

Some installations may also included a three-pole power

terminal block.

NOTES

Crossover Cable

(packaged separately)

Data/Communication

Cable (tucked in the

bottom of the cabinet)

24VDC Power

and Ground Wire

(tucked in the

bottom of the

cabinet)

G N L

110VAC version shown

Center cabinets have two crossover cable connectors tucked

in the base: one labeled MASTER and one labeled SLAVE.

Crossover cables are used to interconnect master and slave

connectors. Refer to Appendix D for crossover cable connection

diagrams.

FOR EXTERNAL DC POWER SUPPLY INSTALLATION

INSTRUCTIONS, REFER TO APPENDIX C ON PAGE 34.

NOTE