©2015

Alvin & CompAny, inC.

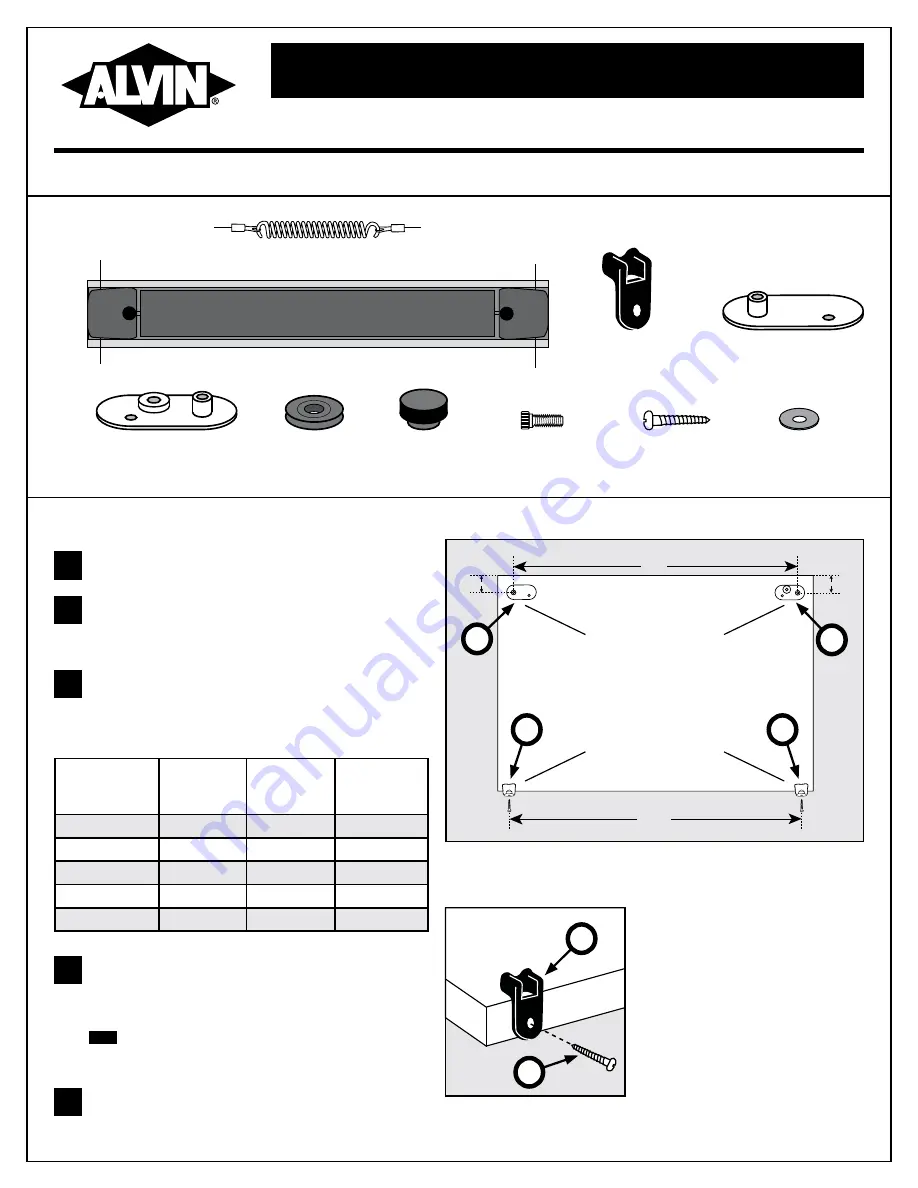

1

Parallel Straightedge

Assembly and Maintenance Instructions

For model series

1101 and 2201

C

2pcs Front

Wire Connectors

E

1pc Right Rear

Wire Connector

D

1pc Left Rear

Wire Connector

F

2pcs Rear

Pulleys

G

1pc Rear

Adjustment

Knob

H

1pc 1/2"

Clinch Stud

J

6pcs 3/4"

Screws

K

2pcs 3/8"

Washers

B

1pc Straightedge with Wire

A

1pc Spring

Tools Required:

Phillips screwdriver and a drill with 1⁄16" bit

Parts Included:

To Assemble:

Verify that all parts shown in parts list are included.

Check that drawing board has a solid outer frame to hold

screws and that it is not warped. Alvin straightedges will

not work properly on warped boards.

Position front and rear wire connectors (

C, D, E

) on top

of drawing board as shown in

Figure 1

. Use chart below

to determine proper spacing. Center the straightedge (

B

)

on the board.

Mark screw positions for front and rear wire connectors

and pre-drill pilot holes about 1/4" deep using a

1/16

"

drill bit. Use care not to drill through the board.

TIP

Wrap masking tape 1/4" from drill tip

to set drilling depth.

Fasten front wire connectors to front edge of board as

shown in

Figure 2

using 3/4" screws (

J

). Fasten screws

half way. Do not fully tighten.

1

2

3

Figure 1

For

Straightedge

Length

Dimension

1

Dimension

2

Dimension

3

30"

27¾"

28¾"

3/4"

36"

33¾"

34¾"

3/4"

42"

39¾"

40¾"

3/4"

48"

45¾"

46¾"

3/4"

60"

57¾"

58¾"

3/4"

Figure 2

4

5

3

3

2

1

Rear Wire Connectors

Front Wire Connectors

D

C

C

E

C

J