©2015

Alvin & CompAny, inC.

2

1101 and 2201 Assembly and Maintenance Instructions

6

7

8

9

10

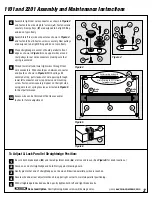

Assemble right rear wire connector as shown in

Figure 3

and fasten to board using 3/4" screws (

J

). Fasten screws

securely. Rear pulleys (

F

) are designed to be tight fitting

and do not spin freely.

Assemble left rear wire connector as shown in

Figure 4

and fasten to board. Fasten screws securely. Rear pulleys

are designed to be tight fitting and do not spin freely.

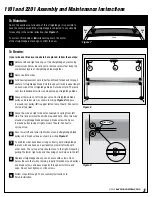

Place straightedge in center of board parallel to front

edge as shown in

Figure 5.

Loop upper wires around

rear pulleys in rear wire connectors making sure that

spring is centered.

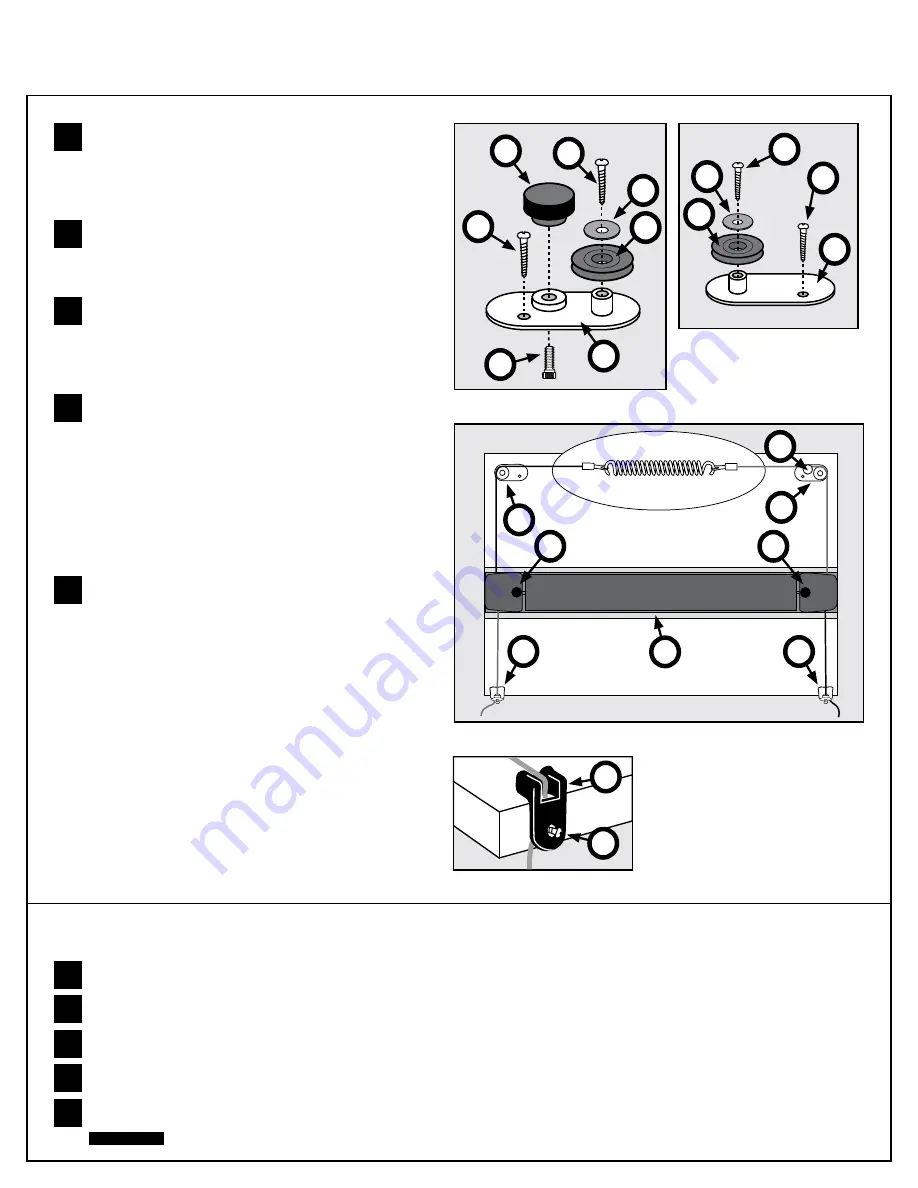

Thread lower left and lower right wires through front

wire connectors. Wire should pass between connector

and board as shown in

Figure 6.

With spring still

centered at top, pull slack out of wire passing through

lower left connector and wrap wire around mounting

screw. Fasten screw securely. Repeat on the right side,

using care to set spring tension as directed in

Figure 5

for best performance.

Excess wire can be trimmed off but leave several

inches for future adjustment.

1

2

3

4

5

To Adjust & Lock Parallel Straightedge Position:

Be sure both brake knobs (

B

) and rear adjustment knob (

G

) are free and loose. (See

Figure 5

for knob locations.)

Grasp one end of straightedge and hold firmly against drawing board.

Gently pivot other end of straightedge up or down until desired parallel position is reached.

Secure wire under rear adjustment knob in upper right corner to maintain parallel positioning.

With straightedge in desired position, gently tighten both left and right brake knobs.

CAUTION

Do not overtighten.

Overtightening brake screws will damage wires.

Figure 4

K

F

J

D

Figure 5

Stretch spring to 2½" in length

for proper tension

Center spring on board

Brake

Knob

B

Brake

Knob

B

D

E

C

C

G

B

Figure 6

Figure 3

G

J

E

H

J

J

K

F

C

J