6

5. Notice

5.1 On the front left side of the oven, there is an adjusting exhaust port puller. Through the red puller of

push and pull to control the exhaust port . Usually the exhaust port in full closed position, It would be

open for a short time only when the oven need to reduce temperature or reduce wetness. Adjustable

distance is 50mm.

5.2 To ensure the baked goods are heated evenly, the up and down of the oven chamber are have fire

regulation plate. If the baked goods color uniform, according to the degree of physical white to brown,

use tools to adjust fire plate position front and back to the appropriate position, if the front side color

more brown,The fire plate should be moved inside; Oppositely, the fire plate should be moved to

another side.

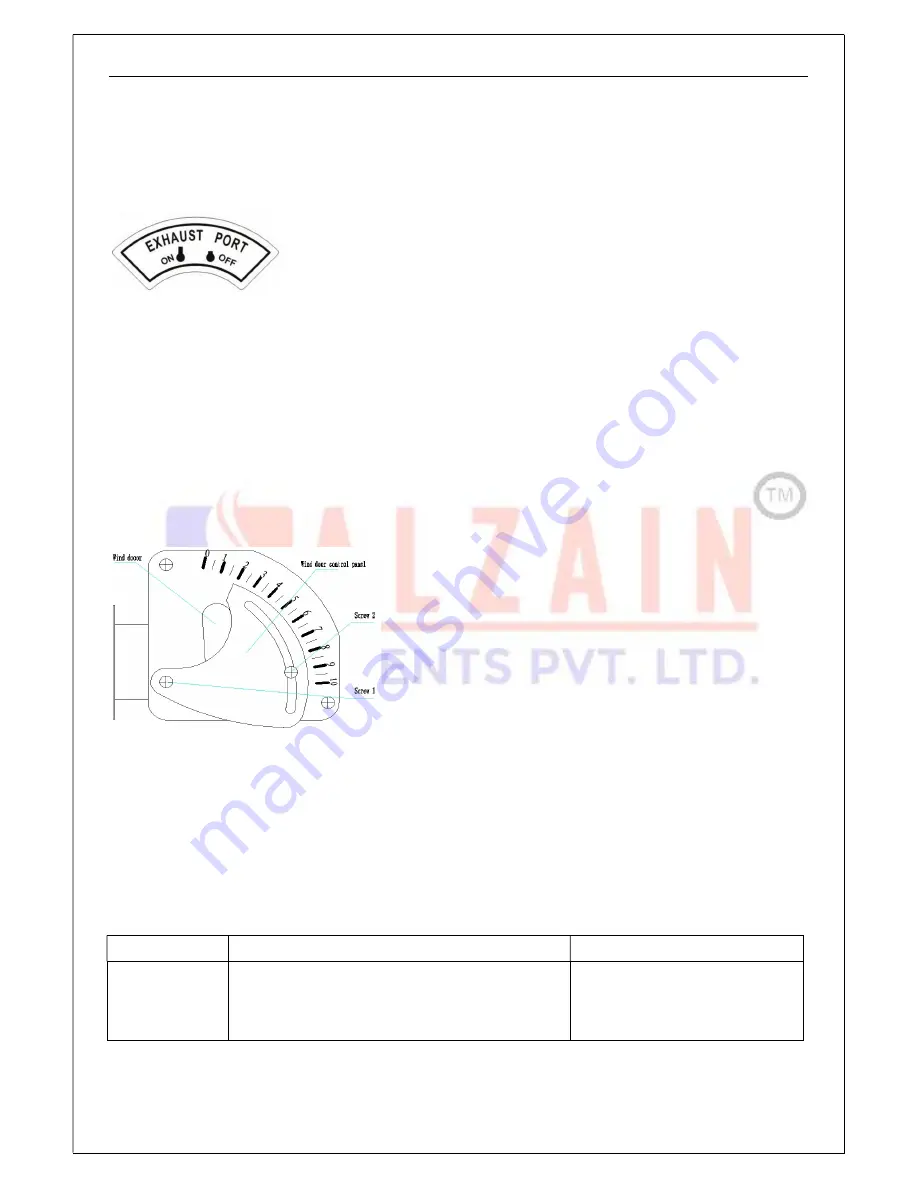

5.3 The electrical control room on the right side panel of the oven, there are blower fans control of

gas-air proportional regulation. If the flame is cyan color, it means lack of air, at this point please loosen

the fan blower screw and rotate the adjusting plate to enlarge the gap, If the flame turns to blue, tighten

the screw. If the flame is away suggests that air volume is too large, reduce the gap to appropriate

position. The factory has already regulated the mixture of air and gas proportion for each oven and

marked.

5.4 If in cold weather, the oven is difficult to ignite, open the right side panel of the electrical control

room, reduce the gap on the blower fan to reduce the air flow, after success igniting, adjust the gap to

normal position.

Warning: the oven chamber is very hot when it is working, it is forbidden to touch, children should

stay away from it! Do not put any flammable and explosive material (such as on the oven , in case of

fire accident.

6. Common failure and solutions

Failure

Cause

Solution

Igniting failure,

no spark at all

1. The electric parts failure.

2.The setting temperature is lower than chamber

temperature

3. Run out of gas.

1.Check the electric parts.

2. Reset the temperature.

3. Check the gas cylinder.