CHAPTER 1: SYSTEM DESCRIPTION

THIN-LINE

®

SERIES 180M WELD HEADS

1-2

990-133

Weld Force

The weld force is continuously adjustable from a minimum of 22.2 N (5 pounds) to a maximum of 445

N (100 pounds) Settings are quickly reproduced by using the force adjustment knob and easy-to-read

visual scale. An adjustable tare spring allows you to compensate for the weight of non-standard

electrode holders. An adjustment screw allows you to adjust the sensitivity of the force-firing switch.

Weld force is applied via a foot pedal in the case of the manual weld head model. It is applied via an air

cylinder in the case of an air-actuated model.

Adjustable Stops

All of the Series 180M Weld Heads have adjustable upstops and downstops. You can use the downstop

to limit excessive over-travel. You can use the upstop to reduce the stroke and, therefore, the travel time

of the head. This is a particularly useful feature when using the head in an automated system.

Electrode Holders

Electrode holders for the Models 180MF, and 180MA use 6 mm diameter, ES0800M Series Electrodes.

Welding Cables

Depending upon model, either #2 or #2/0 Welding Cables are provided to connect Series 180M Heads to

the power source. Miyachi Unitek Heads deliver maximum performance when used with the

appropriate Miyachi Unitek power sources.

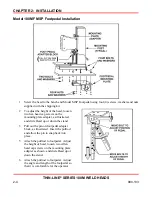

Footpedal Actuation

The Series 180MF Weld Head is manually actuated using the Model MSP, Swing Action Footpedal,

which provides an approximate 5 to 1 mechanical advantage.

EZ-AIR

Actuation

The Model 180A-EZ weld head is equipped with factory-installed EZ-AIR

,

a Miyachi Unitek pneumatic

control that actuates the electrodes and maintains a preset firing force. At a predetermined firing force,

EZ-AIR

closes the inlet and outlet valves to the weld head actuation cylinder and eliminates over-force.

Series 180 air-actuated heads are easy to incorporate into automated welding systems. EZ-AIR can be

energized by most of the Miyachi Unitek power sources, or by a Model FSAC Footswitch. The

Footswitch can be a single or two-level type, dependent upon the power supply and the user's

preference.

For EZ-AIR instructions, see the separate EZ-AIR

Operator Manual supplied with the weld head.

Summary of Contents for THIN-LINE 180 M Series

Page 1: ...990 133 REV F WELD HEAD THINLINE 180 M SERIES OPERATION MANUAL ...

Page 34: ......

Page 38: ......

Page 42: ......