THIN-LINE

®

SERIES 180M WELD HEADS

990-133

2-1

CHAPTER 2

INSTALLATION

Section I. Introduction

Overview

Before

you start installation, become familiar with the specific model you are using. Series 180M Weld

heads come in different sizes and configurations, which require different stands and installation hardware.

Despite differences from model-to-model, the installation principle is the

same

for each head:

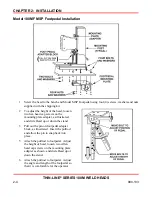

If not already attached, the weld head mounting post is attached to the stand.

The weld head stand is bolted securely to a workbench.

If not already attached, the weld head is attached to the mounting post.

If necessary, the air head (if used), foot pedal (if used), and optics (if used) are installed.

Electrodes and weld cables are installed on the weld head.

Requirements

Work Area

We recommend that you install your weld head in a well-ventilated area that is free from excessive dirt

and moisture. The workstation must be stable, free from vibration, and capable of supporting the

combined weight of the head, its accessories, and the weld energy power supply and welding

transformer. The combined system weight can reach approximately 54.4 kg (120 lbs).

Utilities

AC Power

For Model 180MF – None required.

For Models 180MA-- Included in Miyachi Unitek weld energy power supplies.

Compressed Air

For Models 180MA only. 4.5 bar (65 psi) minimum.

Summary of Contents for THIN-LINE 180 M Series

Page 1: ...990 133 REV F WELD HEAD THINLINE 180 M SERIES OPERATION MANUAL ...

Page 34: ......

Page 38: ......

Page 42: ......