THIN-LINE

®

SERIES 180M WELD HEADS

990-133

4-1

CHAPTER 4

USER MAINTENANCE

Section I. General Maintenance

Inspection

Clean all electrical connections every six months to minimize welding circuit resistance. Inspect all

bearings and braces for excessive wear every three years and replace as necessary.

Lubrication

All bearing surfaces are designed for non-lubricated operation. Do

not

oil any bearings or sleeves

except

for the use of a dry lubricant on weld heads used in automated, air actuated systems.

Section II. Electrode Cleaning

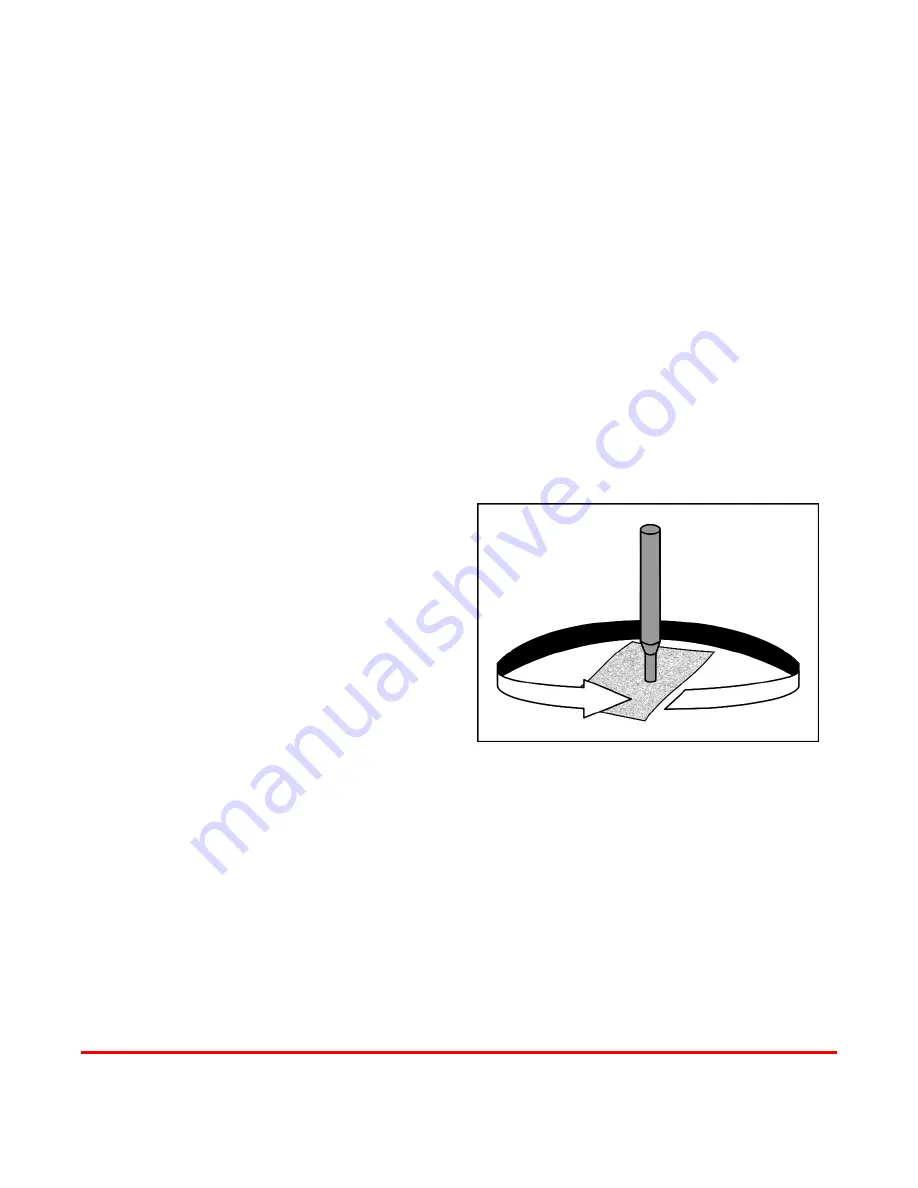

1

Re-surface tips periodically to remove

oxides and welding debris from the

electrodes.

2

Set the

WELD/NO WELD

Switch on

the welding power supply, or control, to

the

NO WELD

position.

3

Clean the electrodes using 400 to 600

grit emery paper. Fold the emery paper

over a

flat, rigid backing

with the grit

surface facing out. The rigid backing

will maintain the "flatness" of the

electrode face during cleaning.

4

Place emery paper and backing between electrodes. If the head is air actuated, reduce the

pressure on the top of the cylinder. Actuate the head. The electrodes should contact with the

paper with a force which is low enough to allow the paper to be moved without damaging its

surface. Move the paper in a circular motion while maintaining the contact force.

5

Wipe the electrodes so that they are clean.

Summary of Contents for THIN-LINE 180 M Series

Page 1: ...990 133 REV F WELD HEAD THINLINE 180 M SERIES OPERATION MANUAL ...

Page 34: ......

Page 38: ......

Page 42: ......