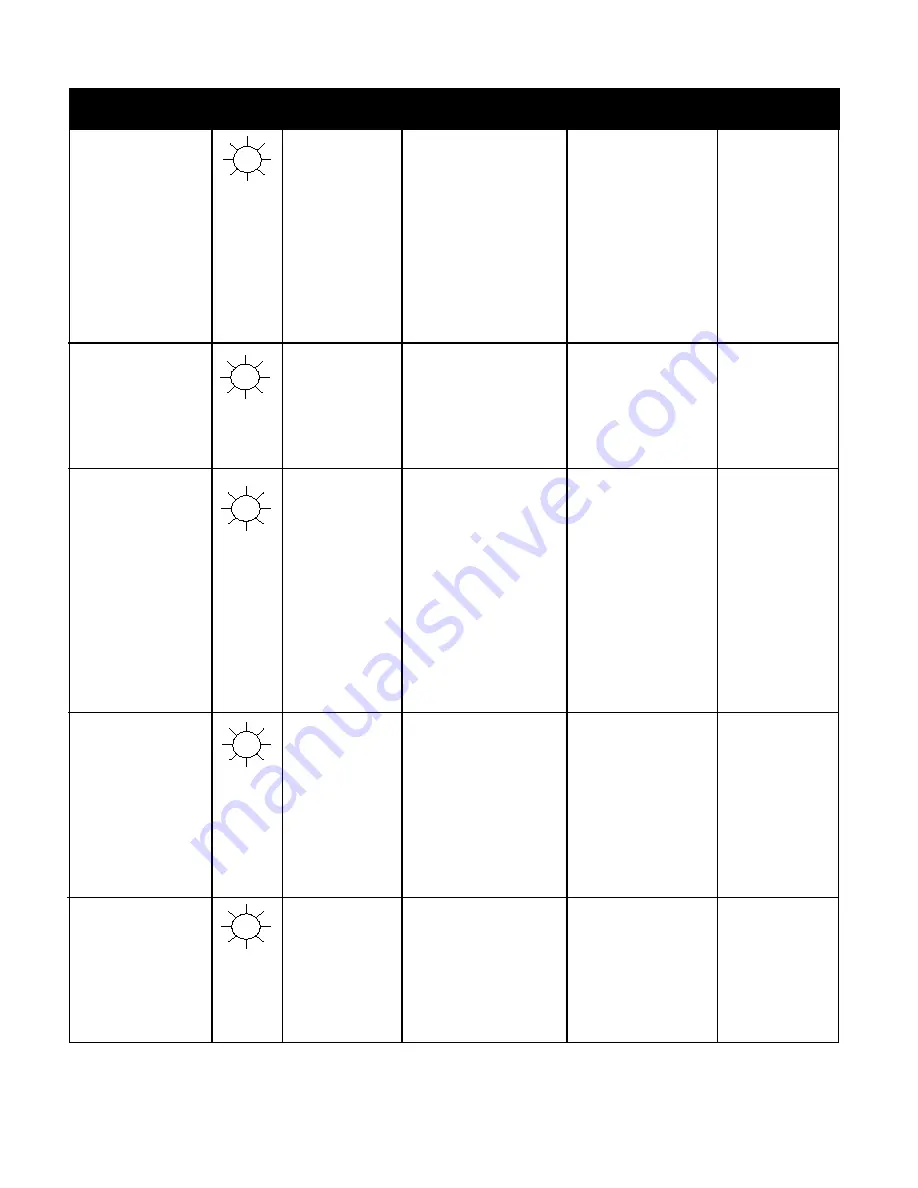

TROUBLESHOOTING

37

1

Integrated control module will automatically attempt to reset from lockout after one hour.

2

LED Flash code will cease if power to the control module is interrupted through the disconnect or door switch.

• Circulator blower runs

continuously. No furnace

operation.

• Integrated control

module diagnostic

LED

is flashing

FOUR

(4)

flashes.

• Primary limit circuit

is open.

• Check primary limit.

Replace if necessary.

• Check filters and

ductwork for blockage.

Clean filters or remove

obstruction.

• Check circulator blower

speed and performance.

Correct speed or replace

blower if necessary.

• Tighten or correct wiring

connection.

• Turn power OFF

prior to repair.

• Replace primary

limit with proper

replacement part.

• Replace blow-

er with correct

replacement part.

4

4 FLASHES

• Faulty primary limit switch.

• Insufficient conditioned air

over the heat exchanger.

Blocked filters, restrictive

ductwork, improper circula-

tor blower speed, or failed

circulator blower.

• Loose or improperly con-

nected wiring.

Fault Description(s)

Possible Causes

Corrective Action

Cautions and

Notes

Symptoms of Abnormal

Operation

Associated

LED Code

2

• Normal furnace opera-

tion.

• Integrated control

module diagnostic

LED

is flashing

SEVEN

(7)

flashes.

• Flame sense micro-

amp signal is low.

• Clean flame sensor if

coated/oxidized.

• Inspect for proper sensor

alignment.

• Check inlet air piping for

blockage, proper length,

elbows, and termination.

• Compare current gas

pressure to rating plate

info. Adjust as needed.

• Turn power OFF

prior to repair.

• Clean flame sen

-

sor

• See “Vent/Flue

Pipe” section for

piping details.

• See rating plate

for proper gas

pressure.

7

7 FLASHES

• Flame sensor is coated/

oxidized.

• Flame sensor incorrectly

positioned in burner flame.

• Lazy burner flame due to

improper gas pressure or

combustion air.

• Induced draft blower and

circulation blower runs

continuously. No furnace

operation.

• Integrated control

module diagnostic

LED

is flashing

FIVE

(5)

flashes

.

• Flame sensed with

no call for heat.

• Correct short at flame

sensor or in flame

sensor wiring.

• Turn power OFF

prior to repair.

5

5 FLASHES

• Short to ground in flame

sense circuit.

• Circulator blower runs

continuously. No furnace

operation.

• Integrated control mod-

ule diagnostic

LED

is

flashing

SIX

(6) flashes.

• Rollout limit circuit is

open.

• Check burners for proper

alignment.

• Check flue and air inlet

piping for blockage, prop-

er length, elbows, and

termination. Correct as

necessary.

• Check rollout limit. Re-

place if necessary.

• Check induced draft blow-

er for proper performance.

Replace, if necessary.

• Tighten or correct wiring

connection.

• Turn power OFF

prior to repair.

• See “Vent/Flue

Pipe” section for

piping details.

• Replace rollout

limit with correct

replacement part.

• Replace induced

draft blower with

correct replace-

ment part.

6

6 FLASHES

• Flame rollout.

• Misaligned burners, blocked

flue and/or air inlet pipe, or

failed induced draft blower.

• Loose or improperly con-

nected wiring.

• Faulty rollout limit.

• Furnace fails to operate.

• Integrated control mod-

ule diagnostic

LED

is

flashing

continuously

.

• Polarity of 115 or

24 volt power is

reversed.

• Review wiring diagram

to correct polarity.

• Reverse orange and

gray wires going to

transformer.

• Verify proper ground.

Correct if necessary.

• Turn power OFF

prior to repair.

C

CONTINUOUS/

RAPID FLASH

• Polarity of 115 volt AC pow-

er to furnace or integrated

control module is reversed.

• Orange and gray wires to

transformer are reversed.

• Poor unit ground.

PCBBF145(S) CONTROL BOARD