SS-AMVM96

www.amana-hac.com

11

10 www.amana-hac.com

SS-AMVM96

P

roduCt

s

PeCiFiCAtions

P

roduCt

s

PeCiFiCAtions

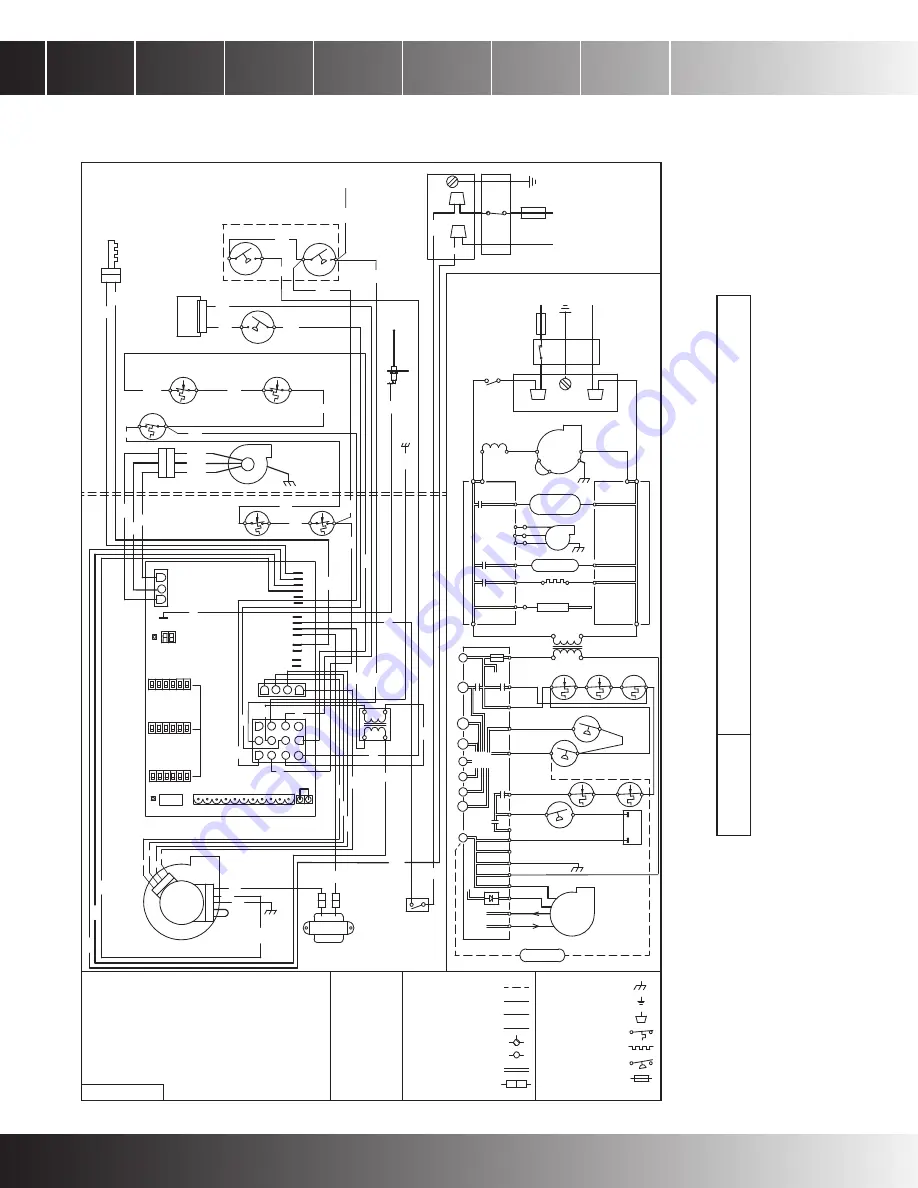

w

iring

d

iAgrAM

Wiring

is subject

to change. Al

wa

ys

refer to the wiring

diag

ram

or the

unit

for

the most up-to-da

te

wiring

.

⚠

W

arning

High

Voltage:

Disconnect

all power

bef

or

e

ser

vicing

or

installing

this

unit.

Multiple

power

sour

ces ma

y be pr

esent.

Failur

e to do so ma

y cause pr

operty damage, per

sonal injur

y, or dea

th.

⚡

OPTIONAL

OPTIONAL

OPTIONAL

TR (9)

PRESS. SWITCH

FRONT COVER

LIMIT CONTROLS

MANUAL RESET ROLLOUT

PRESS. SWITCH

LOW FIRE PRESS.

LIMIT CONTROL

AUTO RESET PRIMARY

AUTO RESET AUXILIARY LIMIT

24 VAC

TO +VDC

TR (5)

FUSE 3A

40 VA

HOT SURFACE

3Ø ID

INTEGR

ATED

C

O

NTR

OL M

O

D

U

LE

AIR CLEANER

115kBTU MODELS

POLARIZED AND

MUST BE PROPERLY

WIRING TO UNIT

BEFORE SERVICING

DISCONNECT POWER

OVERCURRENT PROTECTION DEVICE

Ø /60 HZ POWER SUPPLY WITH

TO 115VAC/1

SWITCH ASSEMBLY

ID BLOWER TWO-STAGE PRESSURE

SWITCH

LOW FIRE

(HONEY WELL)

GAS VALVE

2 CIRCUIT

PRESSURE SWITCH

FRONT COVER

(SINGLE CONTROL ON 45 kBTU)

MANUAL RESET ROLLOUT LIMIT CONTROLS

LIMIT CONTROL

AUTO RESET PRIMARY

BURNER COMPARTMENT

BLOWER COMPARTMENT

AUTO RESET

LIMIT CONTROL

FU

R

NACE CONTROL

M

OD

ULE

M

O

D

UL

AT

ING I

N

TERGRA

TED

CO

OL TAP

S

HE

AT TAPS

FA

N TAPS

DIP SWITCH

ES

HE

AT O

FF

HE

AT SET

UP

CO

OL S

ETUP

PUL

L UP

PUL

L D

OWN

24 V THERMOSTAT CONNECTIONS

24V HU

M.

INTEGR

ATED

C

O

NTR

OL M

O

D

U

LE

24V TH

ER

M

OSTAT

CO

N

NE

CTIO

NS

115kBTU MODELS

(OPEN WHEN

DOOR SWITCH

24 V 3A

ECM MTR

IN STANDBY (NO THERMOSTAT INPUTS)

RECENT, DEPRESS SWITCH FOR MORE THAN 2 SECONDS WHILE

5. TO RECALL THE LAST 10 FAULTS, MOST RECENT TO LEAST

N.E.C. AND LOCAL CODES.

4. UNIT MUST BE PERMANENTLY GROUNDED AND CONFORM TO

LEAST 105°C. USE COPPER CONDUCTORS ONLY.

WIRING MATERIAL HAVING A TEMPERATURE RATING OF AT

FURNACE MUST BE REPLACED, IT MUST BE REPLACED WITH

3. IF ANY OF THE ORIGINAL WIRE AS SUPPLIED WITH THE

USED WHEN SERVICING.

2. MANUFACTURER'S SPECIFIED REPLACEMENT PARTS MUST BE

1. SET HEAT ANTICIPATOR ON ROOM THERMOSTAT AT 0.7 AMPS.

BK BLACK

PU PURPLE

YL YELLOW

BL BLUE

WH WHITE

BR BROWN

PK PINK

COLOR CODES:

PLUG CONNECTION

INTEGRATED CONTROL

INTERNAL TO

HI VOLTAGE FIELD

HI VOLTAGE (115V)

LOW VOLTAGE (24V)

LOW VOLTAGE FIELD

PROT. DEVICE

SWITCH PRESSURE

SWITCH (TEMP)

FIELD SPLICE

EQUIPMENT GND

PROPERLY POLARIZED

TO UNIT MUST BE

SERVICING WIRING.

POWER BEFORE

POWER SUPPLY WITH

115 VAC/1

HZ

Ø /60

TO

MICRO

TO

R

GND (4)

+ VDC (1)

RX (2)

TX (3)

CIRCULATOR

INDOOR

AIR

BLWR

RD GY

BL

BK

HUMIDIFIER

GND

PROTECTION

DEVICE

LINE

RD

TO

C

BK

RD

IGNITER

FLAME

SENSOR

INTEGRATED CONTROL

MODULE

OR

TERMINAL

OR ORANGE

PM

HARNESS

NO

(12)

3

C

CIRCULATOR

BK

BK

OVERCURRENT

24V

HUM.

0140F00863-B

IGNITER

24

PM

INDUCED

DRAFT

BLOWER

EAC

C

115

VAC

INDUCTOR COIL

C

PU

YL

DEHUM

GND

2

HOT

SURFACE

IGNITER

(7)

NEUTRAL

DOOR

SWITCH

4

3

2

C

HASSIS

GRO

UN

D

WH

VAC

GND

YL

CONNECTOR

HUM

OVERCURRENT

(6)

ONLY

C

MODULATING

DISCONNECT

HIGH FIRE

INDOOR

HUMIDIFIER

N

1

CONTROLS

OR

JUNCTION

BLWR

CIRCULATOR BLOWER

R

1

GND

JUNCTION BOX

NEUTRAL

BLOWER

COMPARTMENT

DOOR OPEN)

C

LINE

BK

4

NEUTRAL

C

FS

2

DISCONNECT

PU

HIGH FIRE

PRESSURE

SWITCH

ONLY

W1

70kBTU,90kBTU,

NO

(8)

O

WH

5

GND (4)

BK

3

IGN

PK

GY

(3)

70kBTU,90kBTU,

NOTES:

PU

L

AIR

WH

Y1

GY GRAY

ELECTRONIC

RD RED

Y2

OR

NEUTRAL

1

(11)

WH

SWITCH

NO

WH

TRANSFORMER

BR

BL

GR

2

GROUNDED.

W2

WARNING:

FIELD GND

WH

115

NEUTRAL

BLWR

JU

N

CTION BOX

GND

1

AND GROUNDED.

RD

GAS

VALVE

PU

INDUCTOR COIL

C

1

VAC

G

C

GR

GR GREEN

FLAME

SENSOR

(2)

PRESSURE

1

L

BR

NO

3

NO

N

GY

OR

TO

MICRO

WARNING:DISCONNECT

PK

AUXILIARY

2

NO

BL

GY

BK

RD

OR

BR

BK

WH

RD

OR

WH

WH

WH

WH

BK

YL

OR

BIAS

2

FUSE

AD

JU

ST

LINE

D

EHU

M

2

3

1

NE

UT

RAL

3

D

E

LAY

1

FLA

ME

SE

NS

OR

4

DIAGNOSTIC

LED'S

O

G

ID B

LOWER

CO

NNE

CTOR

Y2

H

UM

EAC

W1

R

2

Y1

1

C

W2

DEHUM

10

6

3

4

5

2

7

11

1

12

8

9

HSI

AUX

OR

2

GND

(10)

BR

OR

BK

BR

40 VA

TR

ANSFOR

ME

R

GY

RA

MP

ING

BL

GY