10

it will be affected by drafts, hot or cold water pipes or air

ducts in walls, radiant heat from fireplace, lamps, the sun,

television, etc. Consult the Instruction Sheet packaged with

thermostat for mounting instructions.

All units have two stages of heating and two stages of me-

chanical cooling. Units which will have economizers may

use thermostats with two or three stages of cooling. All units

can use single stage or multi-stage thermostats. Refer to

figures later in this section for wiring.

WARNING

To avoid personal injury, electrical shock or death,

disconnect electrical power before servicing or changing

any electrical wiring.

The units are designed for operation on 60 hertz current and

at voltages as shown on the rating plate. All internal wiring

in the unit is complete. It is necessary to bring in the power

supply to the contactor as shown on the unit wiring diagram

which is supplied with each unit. The low voltage wiring must

be connected between the unit control panel and the room

thermostat.

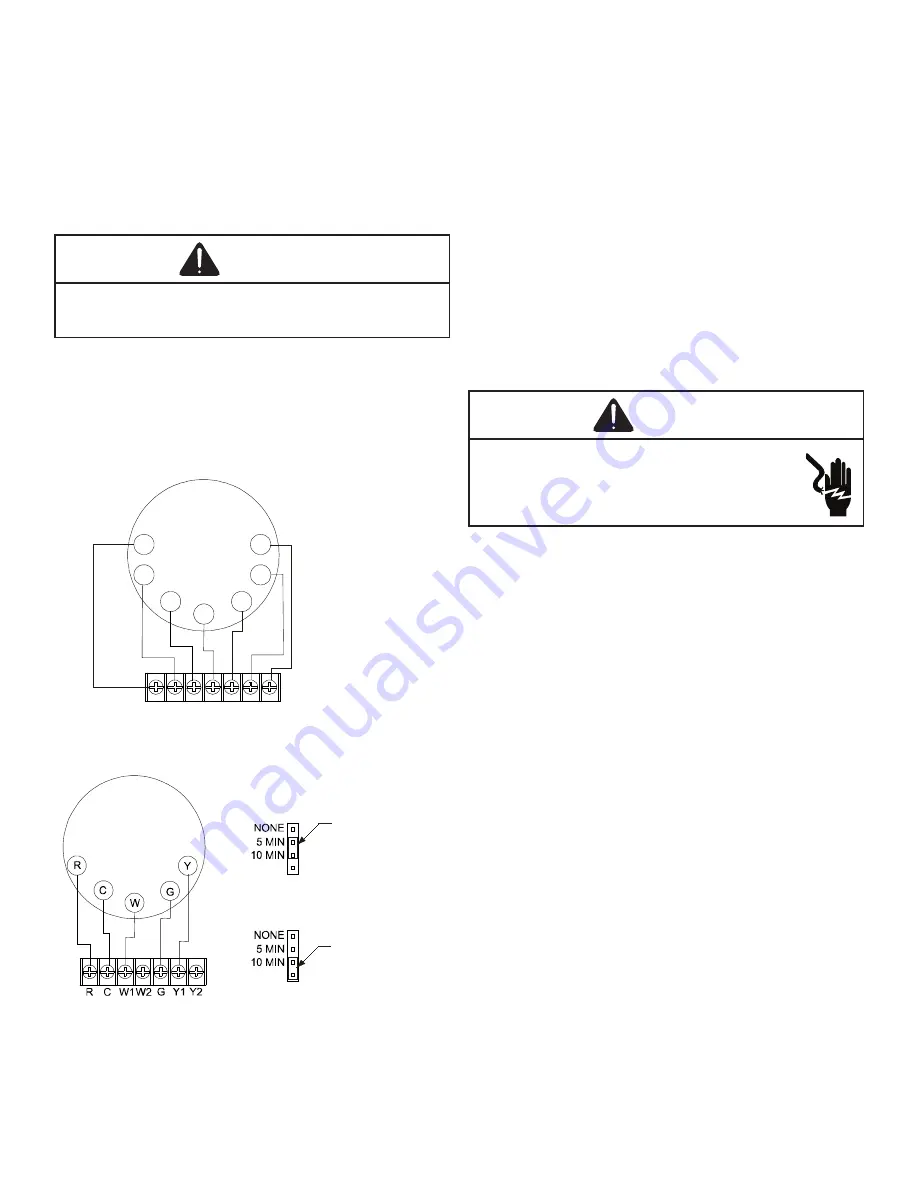

R C W1W2 G Y1 Y2

R

Y2

C

Y1

W1

G

W2

I

ntegrated

Control Module

Thermostat

Two-Stage Heating

with

Two-Stage Cooling

Two-Stage Heating with Two-Stage Cooling

Thermostat Diagram

5 MINUTE DELAY

PERIOD WITH

JUMPER IN THIS

POSITION

10 MINUTE DELAY

PERIOD WITH

JUMPER IN THIS

POSITION

Two-Stage Heating (timed) and Two-Stage Cooling (timed) with Single

Stage Thermostat Diagram

Single Stage Thermostat

To use a single stage thermostat, move jumper located to the

left of the terminal strip labeled “Stage Delay” from NONE to

“5” or “10” minutes. This selection will cause the control to

run on low stage for the selected time (5 or 10 minutes) then

shift to HIGH STAGE. This option controls both cooling and

heating modes. If the jumper is not moved, only low-stage

cool and low-stage heat will operate.

Alternate Fan Only Speed

The APG16 models are equipped with ECM variable speed

motors. Two FAN ONLY speeds are possible with these mo-

tors. To utilize the LOW HEAT blower speed for FAN ONLY

operation, connect the wire from the thermostat’s G terminal

to the ignition control board’s G terminal.

To utilize the alternate FAN ONLY speed, connect the wire

from the thermostat’s G terminal to the unstripped green

wire in the control box. (DO NOT connect the thermostat’s

G terminal to the ignition control’s G terminal.) This alternate

FAN ONLY blower speed is approximately 75% of the HIGH

COOL speed.

24 Volt Dehumidistat Wiring

WARNING

High Voltage!

Disconnect ALL power before servicing or

installing thus unit. Multiple power sources may

be present. Failure to do so may cause property

damage, personal injury, or death.

The optional usage of a dehumidistat allows the unit’s cir

-

culator blower to operate at a slightly lower speed (approx-

imately 80% of desired cooling speed) during a combined

thermostat call for cooling and dehumidistat call for dehu-

midification. This can be done through an independent de

-

humidistat. This lower blower speed enhances dehumidi-

fication of the conditioned air as it passes through the air

conditioning coil. For proper function, a dehumidistat applied

to this package unit must operate on 24 VAC and utilize a

switch which opens on humidity rise. Refer to the unit wiring

diagram for additional wiring details.

To install/connect a dehumidistat:

1. Turn OFF power to unit.

2. To enable the dehumidify function, locate the ECM

blower motor interface module in the unit’s blower

section. Locate the jumper label “HUM” on the interface

module. Cut the jumper to enable dehumidification

(see ECM Blower Motor Interface Module).

3. Secure the dehumidistat neutral wire (typically the

white lead) to the gray, unstripped wire in the unit’s

control box.

4. Secure the dehumidistat low voltage wire (typically

the black lead) to the ignition control’s “R” terminal.

5. Secure the dehumidistat ground wire (typically the

green lead) to the ground screw to the unit’s sheet

metal control box.

NOTE

: Ground wire may not be present on all

dehumidistats.

6. Turn ON power to unit.