11

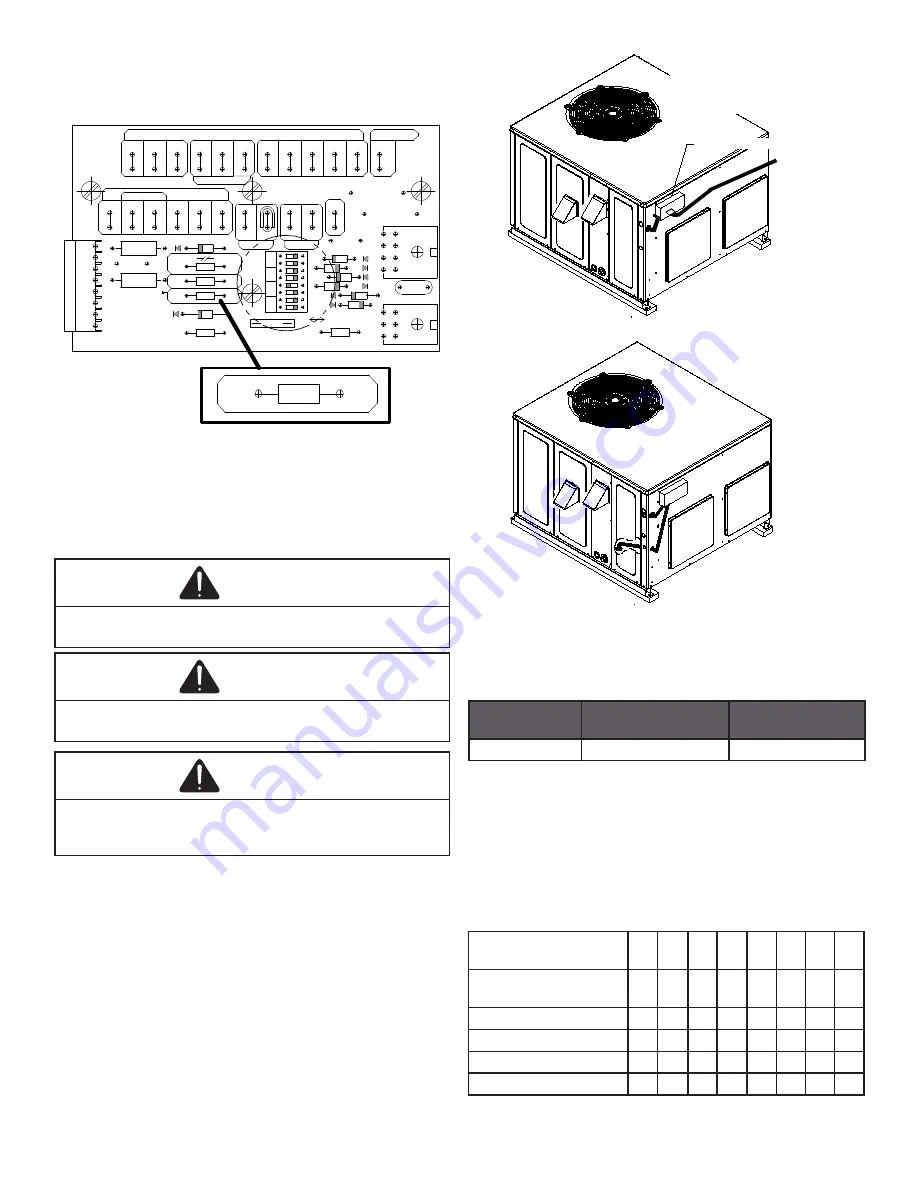

Once the HUM jumper is cut at the ECM motor interface

module, the dehumidify function is enabled during a com-

bination call for cooling (T-Stat) and dehumidification (DE

-

HUMStat).

5

Y1

1

SW

IT

CH

8

7

6

5

4

3

2

1

W1

OT1

OT2

HUM

PJ6

PJ2

PJ4

W2

CR9

HEATER

W1

W2

C

R

24 VAC

CR8

CR7

CR6

J3

CR5

C2

4

1

J2

CR2

DS

1

CR1

R5

O

FF

O

N

D

IP

E

F1

3A

M P

KESU

CR

1 0

R3

PN. PCB001 02

(CFM)

CONFIGURATION.

DIP SWITCH

FOR PROPER

TO MANUAL

PLEASE REFER

R1

R2

ED

W2

O

COM

YCON

R

HEATPUMP

CONDENSER

OUTDOOR

THERMOSTATS

HUMIDISTAT

HUM

Y/Y2

G

Y1

R

C

OT2

OT1

OTC

O

W/W2

E\W1

J1

HUM

PJ6

EMC Blower Motor Interface Module

Refer to the unit wiring diagram for electrical connections.

When installed, the unit must be electrically grounded in ac-

cordance with local codes or in the absence of local codes,

with the National Electrical Code, ANSI/NFPA No. 70, and/or

the CSA C22.1 Electrical Code. Ensure low voltage connec-

tions are waterproof.

WARNING

To avoid the risk of electrical ground shock, wiring to the

unit must be polarized and grounded.

CAUTION

To avoid property damage or personal injury due to fire, use

only copper conductors.

WARNING

To prevent improper and dangerous operation due to

wiring errors, label all wires prior to disconnection when

servicing controls. Verify proper operation after servicing.

For unit protection, use a fuse or

HACR

circuit breaker that

is in excess of the circuit ampacity, but less than or equal

to the maximum overcurrent protection device. DO NOT

EXCEED THE MAXIMUM OVERCURRENT DEVICE SIZE

SHOWN ON UNIT DATA PLATE.

All line voltage connections must be made through weath-

erproof fittings. All exterior power supply and ground wiring

must be in approved weatherproof conduit. Low voltage

wiring from the unit control panel to the thermostat requires

coded cable. See below for ground level and rooftop wiring.

Electrical Power Directly To Junction Box

Electrical Power Routed Through Bottom of Unit

Note:Junction box location

shown is optional and is

for illustration purposes only.

JUNCTION BOX

Electrical Power Routed Through Bottom of Unit

Typical Electrical Wiring Unit Voltage

High Voltage Wiring

Rated Voltage

Minimum Supply

Voltage

Minimum Supply

Voltage

208/230V

197

253

The unit transformer is factory connected for 230V opera-

tion. If the unit is to operate on 208V, reconnect the trans-

former primary lead as shown on the unit wiring diagram.

The induced draft blower on some models is equipped with

a low speed 230V lead (blue) and a low speed 208V lead

(black). If equipped, connect the induced draft blower low

speed 208V lead (black) in place of the low speed 230V lead

(blue). Place the unused 230V lead on the “PARK” terminal

located on ignition control.

Branch Circuit

Ampacity

15 20 25 30 35 40 45 50

SUPPLY WIRE

LENGTH - FEET

200

6

4

4

4

3

3

2

2

150

8

6

6

4

4

4

3

3

100

10

8

8

6

6

6

4

4

50

14 12 10 10

8

8

6

6