14

On new installations, or if a major component has been re-

placed, the operation of the unit must be checked.

Check unit operation as outlined in the following instructions.

If any sparking, odors, or unusual sounds are encountered,

shut off electrical power and check for wiring errors, or ob

-

structions in or near the blower motors.

Duct covers must

be removed before operating unit.

Rollout Protection Control

The rollout protection device opens, cutting power to the gas

valve, if the flames from the burners are not properly drawn

into the heat exchanger. The rollout protection device is lo-

cated on the burner bracket. The reason for elevated tem-

peratures at the control must be determined and repaired

prior to resetting this manual reset control.

WARNING

To avoid property damage, personal injury or death due to

fire or explosion, a qualified servicer must investigate the

reason for the rollout protection device to open BEFORE

manually resetting the rollout protection device.

Rollout Protection

Rollout Protection on Burner Bracket

Secondary Limit Control

The secondary limit control is located on the top of the blower

scroll assembly. This control opens when elevated tempera-

tures are sensed. Elevated temperatures at the control are

normally caused by blower failure. The reason for the opening

should be determined and repaired prior to resetting.

If the power to the unit is interrupted during the heating cy-

cle, it may cause the secondary limit to trip. Once the blower

compartment temperature drops below the limit reset tem-

perature, the limit will automatically reset.

Secondary

Control Limit

Back of Unit

Secondary Control Limit

Pre-Operation Checks

1. Close the manual gas valve external to the unit.

2. Turn off the electrical power supply to the unit.

3. Set the room thermostat to its lowest possible setting.

4. Remove the heat exchanger door on the side of the

unit by removing screws.

5. This unit is equipped with an ignition device which

automatically lights the main burner. DO NOT try to

light burner by any other method.

6. Move the gas control valve switch to the OFF position.

Do not force.

7. Wait five minutes to clear out any gas.

8. Smell for gas, including near the ground. This is

important because some types of gas are heavier than

air. If you have waited five minutes and you do smell

gas, immediately follow the warnings on page 3 of this

manual. If having waited for five minutes and no gas

smell is noted, move the gas control valve switch to

the ON position.

9. Replace the heat exchanger door on the side of the

unit.

10. Open the manual gas valve external to the unit.

11. Turn on the electrical power supply to the unit.

12. Set the thermostat to desired setting.

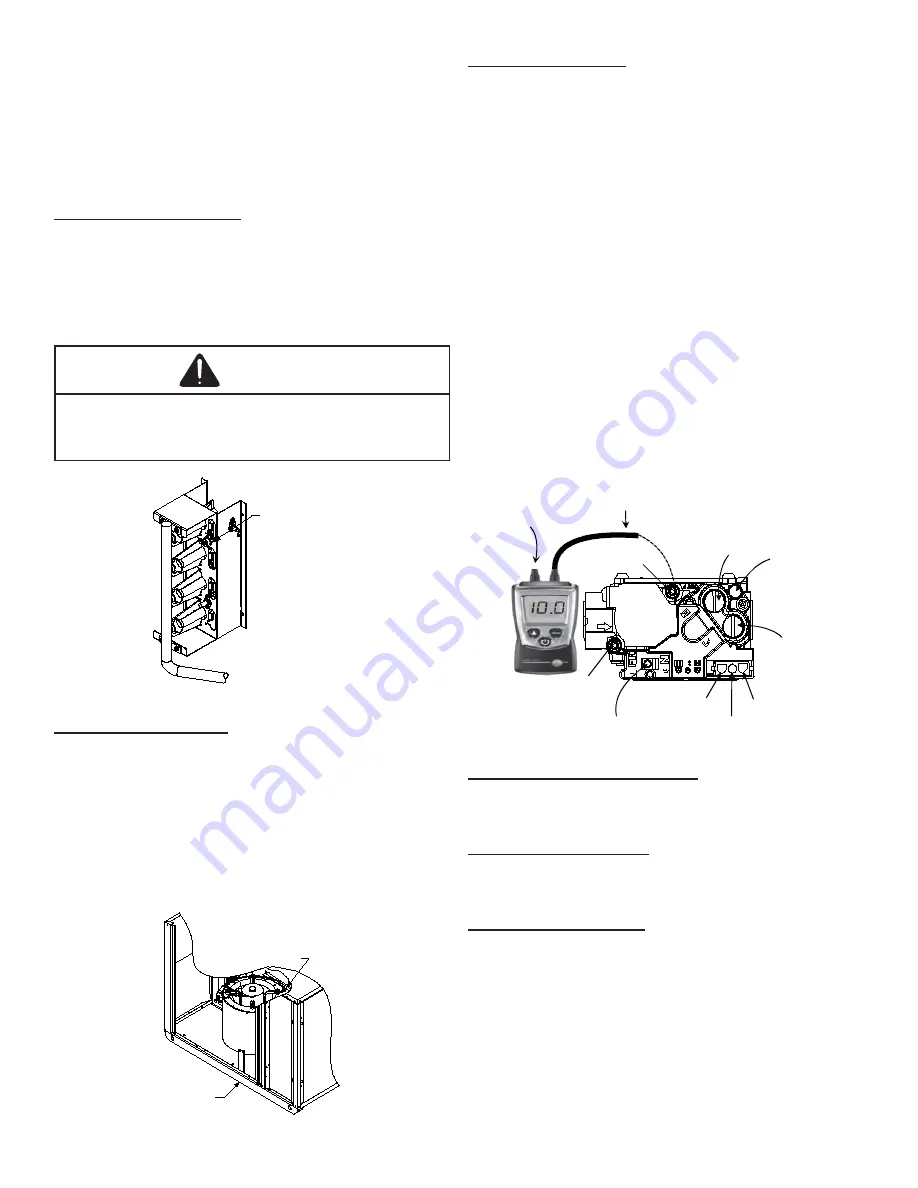

On/Off Switch

Inlet

Pressure Boss

High Fire

Coil Terminal (HI)

Low Fire

Regulator Adjust

Manometer

Manometer

Hose

A

High Fire Regulator

Adjust

Regulator

Vent

Common

Terminal (C)

Coaxial Coil

Terminal (M)

Outlet

Pressure Boss

Open to

Atmosphere

White-Rodgers Model 36G54 connected to Manometer

Gas Supply And Manifold Check

Gas supply pressure and manifold pressure with the burners

operating must be as specified on the rating plate.

Gas Inlet Pressure Check

Gas inlet pressure must be checked and adjusted in accor-

dance to the type of fuel being consumed.

With Power And Gas Off:

NOTE:

Use adapter kit #0151K00000S to measure gas

pressure on White-Rodgers 36G54 gas valves.

1. Back inlet pressure test screw (inlet pressure boss)

out one turn (counterclockwise, not more than one

turn).

Alternately, inlet gas pressure may be measured by

removing the cap from the dripleg and installing a

predrilled cap with a hose barb fitting.

2. Connect a water manometer or adequate gauge to

the inlet pressure tap of the gas valve (or hose barb

fitting on predrilled cap).