15

With Power And Gas On:

3. Put unit into heating cycle and turn on all other gas

consuming appliances.

Natural

Min. 5.0" W.C., Max. 10.0" W.C.

Propane

Min. 11.0" W.C., Max. 13.0" W.C.

INLET GAS PRESSURE

NOTE:

Inlet gas pressure be within the minimum and maxi-

mum value shown. If operating pressures differ from above,

make necessary pressure regulator adjustments, check pip-

ing size, etc., and/or consult with local utility.

4. Turn off all electrical power and gas supply to the

system.

5. Remove manometer hose from the outlet pressure

boss (or remove hose from hose barb).

6. Turn inlet pressure test screw in to seal pressure port

(clockwise, 7 in-lb minimum).

Alternately, remove predrilled cap from dripleg.

Reinstall original cap, sealing with pipe thread

compound.

7. Turn on electrical power and gas supply to the system.

8. Turn on system power and energize valve.

9. Using a leak detection solution or soap suds, check

for leaks at the pressure boss screw (or dripleg cap).

Bubbles forming indicate a leak. SHUT OFF GAS AND

FIX ALL LEAKS IMMEDIATELY.

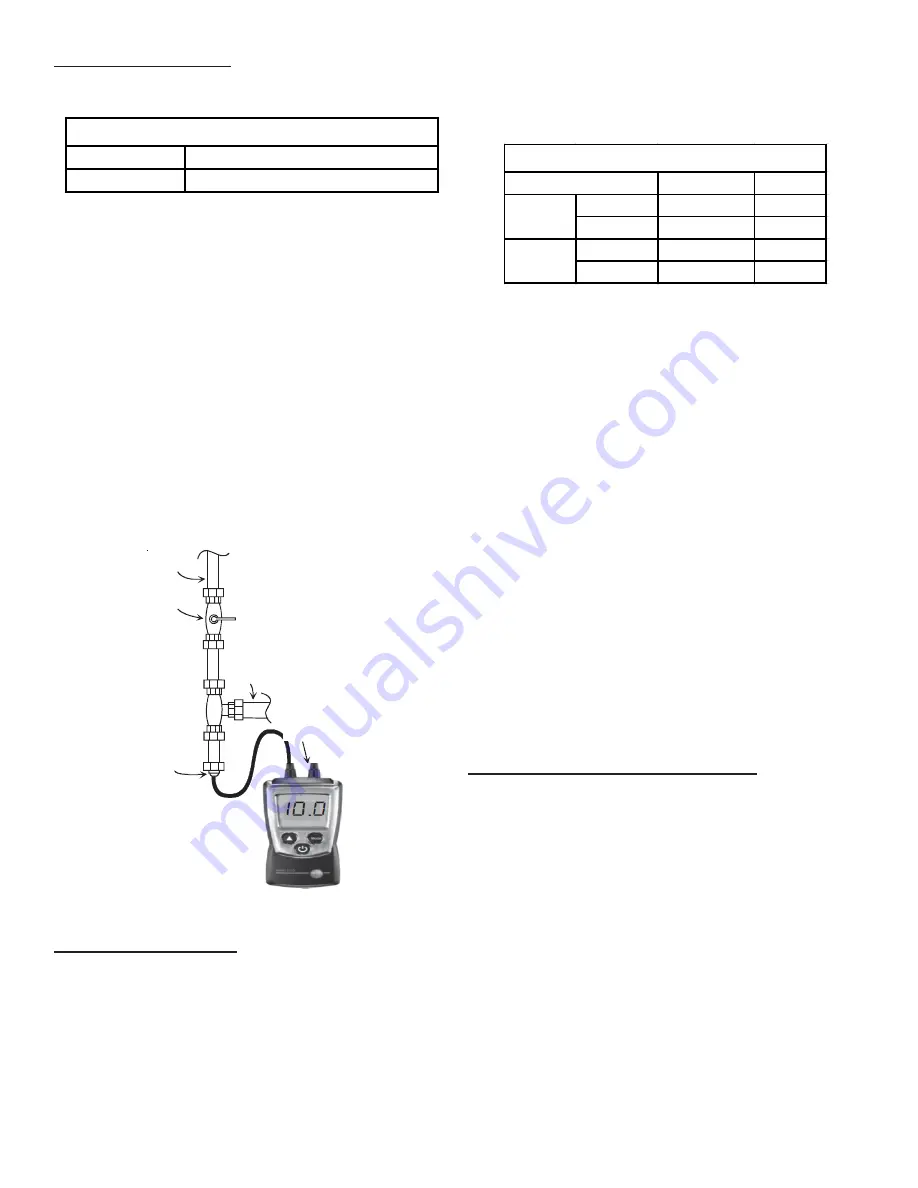

Gas Line

Gas

Shutoff

Valve

Gas Line

To Furnace

Drip Leg Cap

With Fitting

Open To

Atmosphere

Manometer Hose

Manometer

Measuring Inlet Gas Pressure - Alternate Method

Manifold Pressure Check

1 Turn OFF gas to furnace at the manual gas shutoff

valve external to the furnace.

2. Turn off all electrical power to the system.

3. Back outlet pressure test screw (outlet pressure boss)

out one turn (counterclockwise, not more than one

turn).

4. Attach a hose and manometer to the outlet pressure

boss of the valve.

5. Turn ON the gas supply.

6. Turn on power and energize main (M) solenoid. Do

not energize the HI solenoid.

7. Measure gas manifold pressure with burners firing.

Adjust manifold pressure using the Manifold Gas

Pressure table.

Range

Nominal

Low Stage

1.7 - 2.3" w.c.

2.0" w.c.

High Stage

3.2 - 3.8" w.c.

3.5" w.c.

Low Stage

5.7 - 6.3" w.c.

6.0" w.c.

High Stage

9.7 - 10.3" w.c. 10.0" w.c.

Gas

Manifold Gas Pressure

Natural

Propane

Manifold Gas Pressure

8. Remove regulator cover screw from the low (LO)

outlet pressure regulator adjust tower and turn screw

clockwise to increase pressure, or counterclockwise

to decrease pressure.

9. Energize main (M) solenoid as well as the HI terminal.

10. Remove regulator cover screw from the HI outlet

pressure regulator adjust tower and turn screw

clockwise to increase pressure, or counterclockwise

to decrease pressure.

11. Turn off all electrical power and gas supply to the

system.

12. Remove manometer hose from outlet pressure boss.

13. Turn outlet pressure test screw in to seal pressure

port (clockwise, 7 in-lb minimum).

14. Turn on electrical power and gas supply to the system.

15. Turn on system power and energize valve.

16. Using a leak detection solution or soap suds, check

for leaks at pressure boss screw. Bubbles forming

indicate a leak. SHUT OFF GAS AND FIX ALL LEAKS

IMMEDIATELY.

NOTE:

For Natural gas to LP gas conversion, Conversion

Kit “LPM-08” must be used. Consult your dealer for appro-

priate conversion kit(s)

Gas BTU Input Check (Natural Gas Only)

To measure the gas input use a gas meter and proceed as

follows:

1. Turn off gas supply to all other appliances except the

unit.

2. With the unit operating, time the smallest dial on the

meter for one complete revolution. If this is a 2 cubic

foot dial, divide the seconds by 2; if it is a 1 cubic foot

dial, use the seconds as is. This gives the seconds

per cubic foot of gas being delivered to the unit.

3. INPUT=GAS HTG VALUE x 3600 / SEC. PER CUBIC

FOOT

Example:

Natural gas with a heating value of 1000 BTU per

cubic foot and 36 seconds per cubic foot as determined by

Step 2, then:

Input = 1000 x 3600 / 36 = 100,000 BTU per Hour.

NOTE:

BTU content of the gas should be obtained

from the gas supplier. This measured input must not

be greater than shown on the unit rating plate.