17

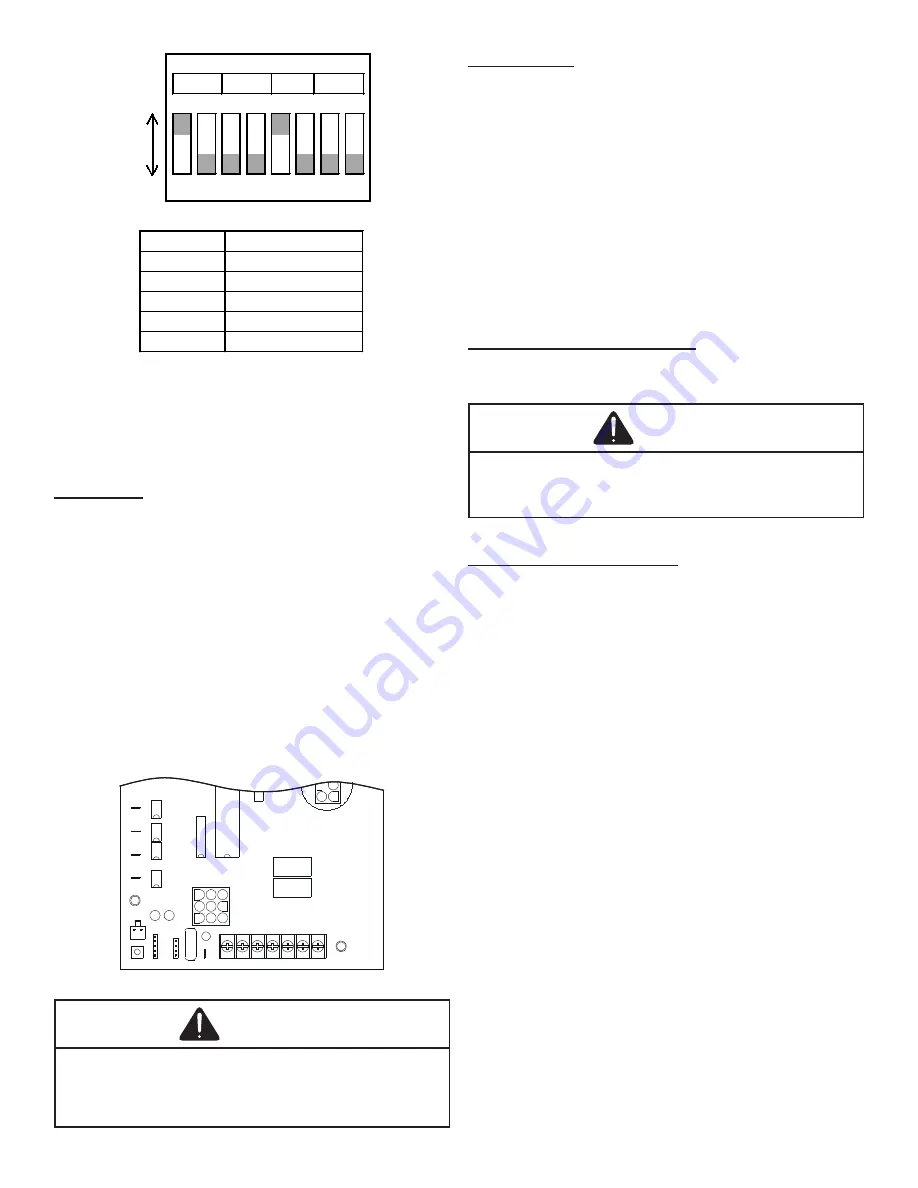

DIP

SWITCH

1 2 3 4 5 6 7 8

ON

• • • • • • • •

OFF

• • • • • • • •

Factory Dipswitch Settings

Switches

Function

1, 2

Heating Speeds

3

Unused

4

OFF for Two-Stage

5, 6

Cooling Speeds

7, 8

Airflow Adjust

DIP Switch Functions

NOTE:

Heating airflow must be adjusted to provide the tem

-

perature rise shown on rating plate. Blower speeds are pro-

grammed to deliver adequate airflow at rated external static

pressure (ESP). Refer to airflow table provided in the

Ap

-

pendix

for details.

Limit Check

Check limit control operation after 15 minutes of operation

by blocking the return air grille(s).

1. After several minutes the main burners must go

OFF. Blower will continue to run.

2. Remove air restrictions and main burners will relight

after a cool down period of a few minutes.

Adjust the thermostat setting below room temperature.

1. Main burners must go OFF.

2. Circulating Air Blower will continue to run for 90,

120, 150 or 180 seconds, depending on the setting.

NOTE:

If necessary, adjust fan OFF delay settings to obtain

satisfactory comfort level.

LO COOL

HI COOL

LO HEAT

HI HEAT

U6

U7

U4

U5

U3

K2

K1

P1

ECON

STAGE

DELAY

SPEEDUP

SW1

FAULT

RECALL

BLOWER

OFF DELAY

F1

R C W1 W2 G Y1 Y2

Control Board (Top)

WARNING

This unit must not be used as a “construction heater” during

the finishing phases of construction on a new structure. This

type of use may result in premature failure of the unit due

to extremely low return air temperatures and exposure to

corrosive or very dirty atmosphere.

Unit Shutdown

1. Set the thermostat to lowest setting.

2. Turn off the electrical power supply to the unit.

3. Remove the heat exchanger door on the side of the

unit by removing screws.

4. Move the gas control valve switch to the OFF position.

Do not force.

5. Close manual gas shutoff valve external to the unit.

6. Replace the heat exchanger door on the unit.

7. If cooling and/or air circulation will be desired, turn

ON the electrical power.

Cooling Startup

NOTE:

The outdoor temperature must be 60°F or higher

before making adjustments to charge.

Compressor Protection Devices

The compressor includes components which are designed to

protect the compressor against abnormal operating conditions.

WARNING

To prevent personal injury or death, always disconnect

electrical power before inspecting or servicing the

unit. NOTE: All compressor protection devices reset

automatically, energizing the contactor and outdoor fan.

Cooling Refrigerant Charging

Check unit charge before putting the cooling section into full

operation. The unit has a thermostatic expansion valve me-

tering device. To ensure the unit is properly charged for the

intended application, check the unit refrigerant sub-cooling at

the condenser. The refrigerant sub-cooling is a function of out-

door ambient temperature and return air temperature of the

conditioned space. It is the installing contractors responsibility

to ensure the proper refrigerant sub-cooling at the condenser

is adjusted for each application. As the outdoor ambient tem-

perature rises the sub-cooling decreases and as the outdoor

ambient temperature lowers, the sub-cooling increases.

NOTE:

Proper sub-cooling adjustment optimizes cooling

performance. Models equipped with thermostatic expansion

valve, charge the system to sub-cooling, range shown on

chart, when necessary, adjust expansion valve stem for su-

perheat setting.

SUPERHEAT

Checking Superheat

Refrigerant gas is considered superheated whenever its

temperature is higher than the saturation temperature cor-

responding to its pressure. The degree of superheat equals

the degrees of temperature increase above the saturation

temperature at existing pressure.

1. Run system at least 10 minutes to allow pressure to

stabilize.

2. Temporarily install thermometer on suction (large) line

near compressor with adequate contact and insulate

for best possible reading.