15

RS1500000 Rev. 2

Component Testing

To avoid risk electrical shock, personal injury, or death,

always disconnect electrical power source to the freezer

before attempting to service, unless test procedures require

power to be connected. When removing any wiring from terminals they must be replaced on the same terminals.

Ensure all ground wires are connected before certifying unit as repaired and/or operational.

WARNING

!

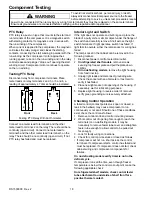

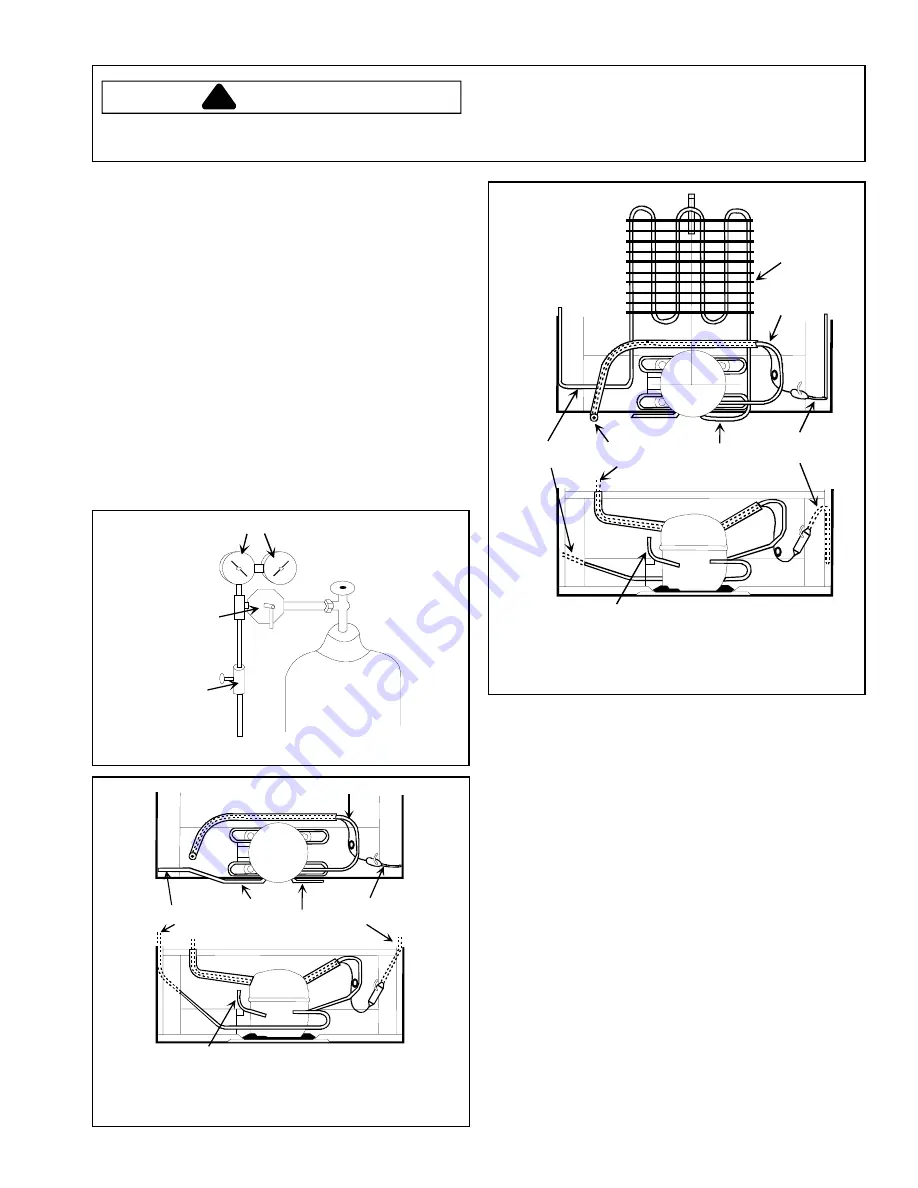

Testing Main Condenser

Before testing condenser, verify no leaks exist

elsewhere.

Condenser loop must be disconnected from the system

and tested separately. The following illustration shows

the tubing as it is routed and fastened in the freezer

cabinet flange.

NOTE:

Verify a leak is not present in any external

tubing or joints before performing the following

test.

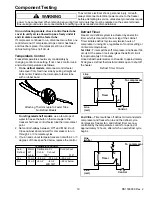

Following equipment is required to test.

An access fitting

A drum of oil pumped nitrogen.

Pressure regulator.

Two gauges.

Line valve and tubing.

Access fitting should be prepared as follows:

Line

valve

Pressure

regulator

Gauges

Nitrogen Tank and Fittings

Suction

Process

From

condensor

To

condensor

Discharge

Tube

process

Compressor Cutting or Unsoldering

Points Refrigerated Shelf Models

Discharge

From

condensor

Tube

process

To

condensor

To

evaporater

Suction

Condensor

bottom

external

Compressor Cutting or Unsoldering

Points No Defrost Models

Prepare equipment as required and test condenser as

follows:

1. Cut tubing at arrow to condenser and from

condenser as shown in the previous illustration.

2. Crimp and solder the end to condenser that enters

into the cabinet.

3. Silver solder access fitting of test equipment to the

end from condenser tube that emerges from the

cabinet.

4. Pressurize the system to 250 pounds with dry

nitrogen. Test all connections for leaks with a soap

solution.

5. Check the pressure gauge. If pressure drops, there is

a leak. However, it may be necessary to allow as

much as 24 hours for test results to verify no leaks

exist. If there are no leaks, reconnect the tubing.

Evacuate and recharge the system.