17

RS1500000 Rev. 2

Component Testing

To avoid risk electrical shock, personal injury, or death,

always disconnect electrical power source to the freezer

before attempting to service, unless test procedures require

power to be connected. When removing any wiring from terminals they must be replaced on the same terminals.

Ensure all ground wires are connected before certifying unit as repaired and/or operational.

WARNING

!

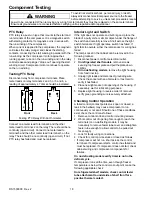

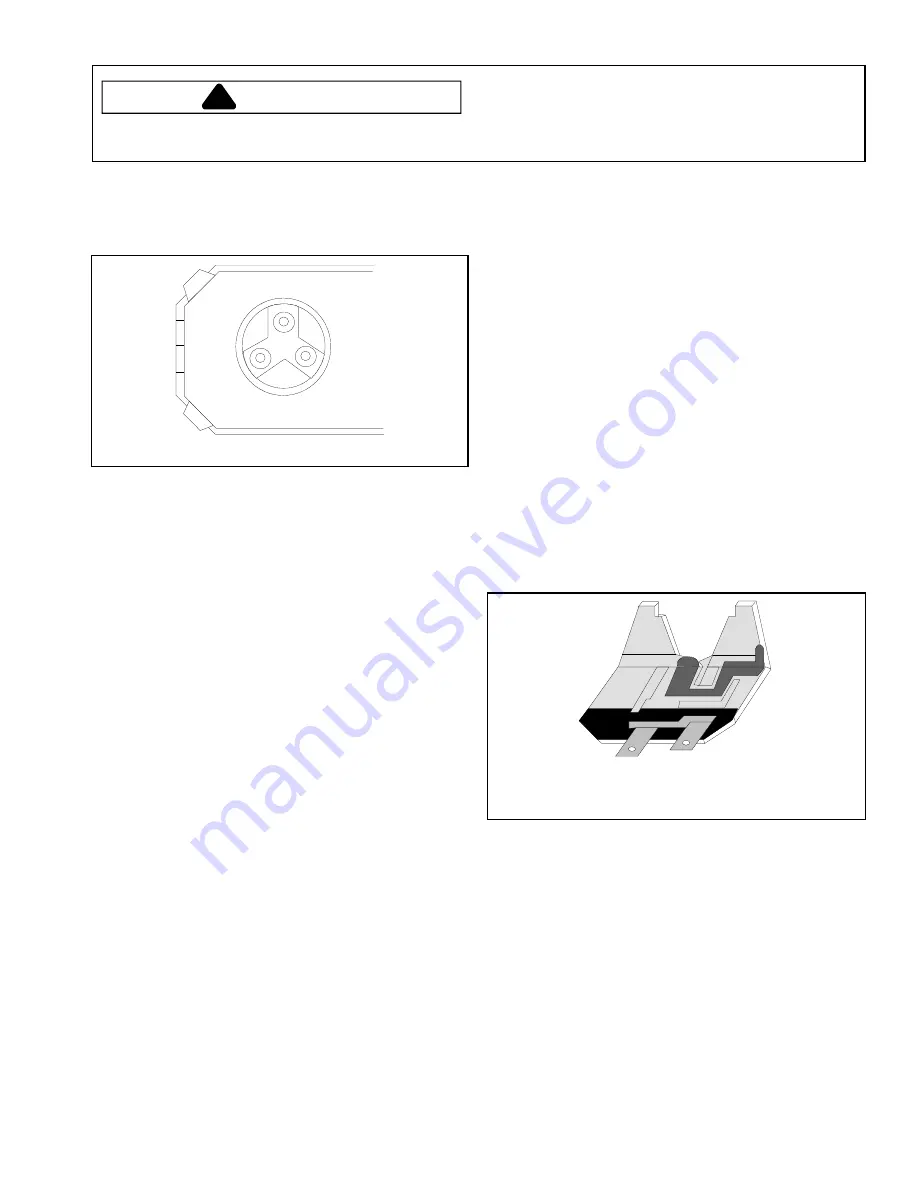

Tester leads are marked RUN, START and

COMMON. Connect common lead to common

terminal, start lead to start terminal and run lead to run

terminal of the compressor.

Run

Common

Start

Compressor Terminals

The other two leads are for the start capacitor. When not

in use, connect the two leads together in the OFF

position. Verify there are no bare leads touching the

cabinet. Plug in the tester cord and flip the switch to

START position. As soon as the compressor starts,

release the switch to RUN position.

If compressor starts, trouble is in another electrical

component (overload protector, starting relay,

temperature control or wiring harness).

If compressor fails to start (or run) compressor has failed

and must be replaced.

Perform continuity check on compressor.

1. Check resistance of compressor windings:

a. Attach ohmmeter between winding C and S,

Ohmmeter indicates <10

W

but > 0

W.

b. Attach ohmmeter between winding C and M,

Ohmmeter indicates <10

W

but > 0

W.

2. Check compressor for grounds:

Attach one ohmmeter lead to compressor case.

Attach second ohmmeter lead to C, then S, then M

terminals on compressor. Ohmmeter indicates

open on each terminal.

Capacitor

Capacitor can be tested by an analog meter. Attach one

meter lead to one terminal and once the other meter lead

touches the second terminal meter will indicate a reading

but will discharge through the meter and indicate no

reading. Reverse the meter leads and indication will be

the same. If testing with a digital meter, the only

indication will be, capacitor has a direct short.

Overload Protector

Overload protector is located under the terminal cover on

the compressor. If compressor becomes overheated

and/or draws too much current, overload trips open and

shuts compressor off. If overload does this repeatedly,

the compressor is cycling on the overload.

Cycling on the overload may be caused by:

Insufficient air circulation around the compressor and

condenser

Pull down overload (caused by a large quantity of

warm food placed in the freezer)

Compressor stalling due to lack of pressure unloading

Low line voltage

Failed starting relay.

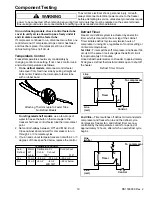

Testing Overload Protector

To test the overload protector, remove compressor

terminal cover. Examine bottom of the overload for

possible signs of arcing. If there are no signs of arcing,

check for continuity across the terminals, there should be

a reading of approximately 0.7 ohms. If continuity is not

indicated replace overload protector.

Overload protector

Overload Protector Terminals

When examining the overload protector, evidence of

arcing is present, replace overload protector.