29

RS1500000 Rev. 0

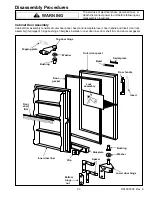

Disassembly Procedures

To avoid risk of electrical shock, personal injury, or

death, disconnect power to unit before following any

disassembly procedures.

WARNING

!

18.Transfer rubber insulating sleeve to replacement heat

exchanger assembly and tape the same points.

19.Clean tubing and silver solder new heat exchanger to

coil with proper flux. Excess flux must be wiped off

after soldering.

20.Clean tubing and silver solder new heat exchanger to

the coil.

21.Work new tubing through rear opening, careful not to

tear rubber sleeve.

22.Position freezer coil and install mounting screws.

Replace styrofoam air blocks at the upper ends of the

coil. This is necessary to channel the air flow properly

through the coil.

23.Carefully form tubing and route it in the same manner

as the original. Use extreme care when bending the

tubing at entrance hole to prevent kinking. Pack entry

with butyl sealer.

24.Clean the suction line and silver solder the joint with

proper flux. Excess flux must be wiped off after

soldering.

25.Install new drier.

26.Visually check all joints for leaks. Evacuate and

recharge the system.

27.Lace the defrost heater leads to both ends of the

freezer coil. Fasten wire leading to fan motor to the

two clips on the mounting panel.

28.Connect white defrost heater lead to white lead-in

wire with spade connector, attach other wire to spade

terminal on fan motor.

29.Secure defrost thermostat to coil and connect lead

wire.

30.Connect green grounding wire to fan motor and to

freezer coil cover.

31.Reinstall coil cover and secure with screws.

32.Test run the unit to verify proper operation.

33.Pinch process tube and cut off the service valve.

Solder the joint and test for leaks.

Replacing Freezer Shelving

Refrigerated

Shelf Models

Current freezer models are equipped with steel shelves

and can be individually repaired or replaced as follows:

1. Disconnect line cord from electrical outlet.

2. Install service valve as close as possible to the tip of

process tube, for easy pinch-off after recharging the

system.

3. Connect a hose to service valve and capture the

charge.

NOTE:

Effective July 1, 1992, before opening any

refrigeration system it is the responsibility of the

service technician to capture the refrigerant for

safe disposal.

4. Remove butyl sealer from tube entry hole in the

cabinet back.

5. Cut the end off of compressor process tube after the

refrigerant has been captured. Attach a service valve

to it, and leave the valve open.

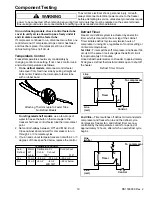

6. Cut drier from condenser tubing. Cut drier from

capillary tube. To cut capillary tube, score the walls

with a knife or file. Cut around entire tube uniformly,

then break it with your fingers.

Score here

then snap tube

1"

Cutting Capillary Tube

7. Straighten heat exchanger tubing to slide tube

through entry hole from inside the cabinet.

8. Remove clamp securing control feeler tube to

underside of second shelf (counting downward).

9. Carefully bend feeler tube down against liner side to

be out of the way.

10.Remove screws securing top freezer plate to liner

top. Front edge of the plate, drops clear of the liner,

disconnect lead wires from interior light, if equipped.

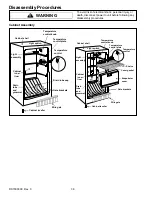

11. Carefully remove each shelf from the food liner

support rails. Push out on liner side just above front

retainer embossment. Lift the shelf front free of the

retainer. If necessary, repeat this operation on the

opposite side.

12.Carefully pull entire shelving assembly out of cabinet

and position to allow detachment of failed shelf.

13.Cut or unsolder failed shelf and remove.

14.Clean joints and solder new shelf to assembly and

paint new joints.

15.Carefully position assembly back in the cabinet,

verifying heat exchanger tubing passes through rear

opening without damaging the rubber sleeve.

16.Carefully work each shelf into its proper support rails.

Replace non-refrigerant shelf in the same manner.

17.Connect wiring to freezer light, if equipped, and

fasten top freezer plate, verifying all spacers are in

place.