39

RS1500000 Rev. 0

Service Information

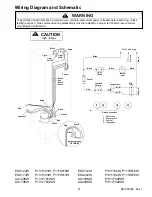

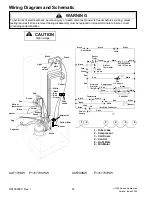

To avoid risk of electrical shock, personal injury, or death,

always disconnect electrical power source to the freezer

before attempting to service unless test procedures require power to be connected. When removing any wiring from

terminals, replace on the same terminals. Ensure all ground wires are connected before certifying unit as repaired

and/or operational.

WARNING

!

Operational Testing

Thorough operational checking of freezer will minimize

future service calls.

1. Set control to No. 4 position.

2. Place thermometer in the center of the freezer.

Operating temperatures should cycle b3°F

(cut in) to -2°F (cut out) in an empty cabinet.

3. Check thoroughly with reliable leak detector for leaks.

4. Attach a cycle recorder and plug into outlet. Verify

power source is not overloaded with other

appliances.

Compare test results with "Performance Data" table, see

"Component Testing" section, page 12.

Running time will vary according to design characteristics

of the system and will be influenced by conditions listed

below:

Temperature control setting

Room temperature

Length of time and number of lid openings

Quantity and temperature of food placed in freezer

Service Hints

Owner's Manual

If you find customer is not familiar with "Owner's

Manual", acquaint customer with manual.

Usage

Common types of abnormal usage that may lead to

service calls include the following:

1. Excessive unfrozen food load:

Amount of unfrozen food to be placed in freezer

should not exceed approximately 3 pounds per

cubic foot in 24 hours, unless otherwise noted.

Recommend to customer that larger quantities of

food be frozen commercially before placing in

freezer.

Larger unfrozen food loads may cause customer

complaints of "continuous running" or may raise

temperature of frozen food. Larger unfrozen food

loads may also result in longer freezing times.

2. Excessive Lid Opening:

Freezer is not designed to be operated as a

refrigerator. Length of time and number of lid

openings should be kept to minimum.

Compressor "On" And "Off" Periods

Variations in compressor cycles per hour are affected by

factors such as usage, ambient conditions, electric

power supply and others. Compressor off period is at

least 8 minutes. Tripping on overload may occur.

Noise

Some noise, especially during starting and stopping of

compressor, is normal. In some cases noise, described

by customer as "gurgling," is experienced. This "gurgling"

noise is caused by liquid entering evaporator.

Voids In Urethane Foam Insulation

Some condensation occurs on outer casing of freezer,

when humidity is 85% or higher, which is considered

normal.

If condensation occurs at lower humidity level or

persistently causes dripping water, there may be a

void in the foam insulation where condensation

occurs. Theoretically, voids can occur in any part of

the freezer insulation.

1. Diagnosing presence of a void:

a. Freezer should be operating and food-liner

temperature should be close to 0°F.

b. Disconnect power supply to freezer and wait 10

minutes. This will allow condenser and skin of

outer casing to cool down to room temperature.

c. Move your palm around skin of outer casing,

searching for cold spots.

If a void exists, area will feel colder than

neighboring area. To access that "cold spot" is

a void, try to flex sheet metal with your thumb.

Metal over a void will be more flexible than

metal backed with foam.

If no void is found, observed condensation or

dripping, which is caused by insulation void on

the food-liner side of the foam insulation.

2. Action to be taken:

If void is in an area which can be repaired in the

field (bottom or back) using the "foam kit",

proceed with the repair. If void is found in an area

which is exposed to view, then freezer should be

returned to source.