RS1500000 Rev. 0

44

Service Information

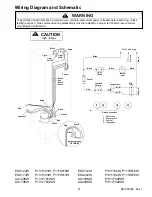

To avoid risk of electrical shock, personal injury, or death,

always disconnect electrical power source to the freezer

before attempting to service unless test procedures require power to be connected. When removing any wiring from

terminals, replace on the same terminals. Ensure all ground wires are connected before certifying unit as repaired

and/or operational.

WARNING

!

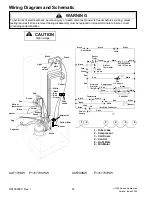

Service Equipment

CAUTION

!

Service equipment for HFC134a systems must be

used exclusively with HFC134a refrigerant. Do not use

this equipment to service devices using other types of

refrigerant (for example, CFC12 or CFC22

refrigerants).

Listed below are the tools and equipment needed for

proper servicing of HFC134a systems.

NOTE:

Once equipment is designated for HFC134a

use, it must be exclusively use for HFC134a

only. An

*

will identify the following equipment.

* Evacuation pump

Check with vacuum pump

supplier to verify equipment is compatible for

HFC134a. Robinair, Model 15600, 2 stage, 170 liters

(6 cubic feet) per minute pump is recommended.

* Four-way manifold gauge set with low loss quick

couplers

Leak detector

* Charging cylinder

* Line piercing saddle valve

Seals must be

HFC134a and ester oil compatible. Line piercing

valves may be used for diagnosis but are not suitable

for evacuation or charging, due to minute holes

pierced in tubing. Do not leave mechanical access

valves on system. Valves eventually will leak.

Molecules of HFC134a are smaller than other

refrigerants and will leak where other refrigerants

would not.

* Swaging tools

* Flaring tools

* Tubing cutter

Flux

Sil-Fos

Silver solder

* Oil for swaging and flaring

* Copper tubing

Dry nitrogen

99.5% minimum purity, with -40°C (-40°F) or lower

dew point

Crimp tool

Tube bender

Micron vacuum gauge

* Process tube adaptor kit

Heat trap paste

* Appliance grade HFC134a

Drier Replacement

Before opening sealed system, recover HFC134a

refrigerant for safe disposal.

Every time sealed HFC134a system is repaired, drier

filter must be replaced. Cut drier out of system by

completing the following steps. Do not unbraze drier

filter. Applying heat to remove drier will allow moisture

into system.

1. Score capillary tube close to drier and break.

2. Reform inlet tube to drier allowing enough space for

large tube cutter.

3. Cut circumference of drier 1-1/4" (3.175 cm), below

condenser inlet tube joint to drier.

4. Remove drier.

5. Unbraze remaining part of drier. Remove drier from

system.

6. Discard drier in safe place. Do not leave drier with

customer.