18

F

AULT

R

ECALL

The integrated control module is equipped with a momentary

push-button switch that can be used to display the last six

faults on the 7 segment LED display. The control must be in

Standby Mode (no thermostat inputs) to use the feature. De-

press the push-button for approximately two seconds and

less than five seconds. The LED display will then display the

six most recent faults beginning with the most recent fault

and decrementing to the least recent fault. The faults may

be cleared by depressing the button for greater than five sec-

onds.

NOTE:

Consecutively repeated faults are displayed a

maximum of three times. Example: A clogged return air filter

causes the air handler’s motor to repeatedly enter a limiting

condition. The control will only store this fault the first three

consecutive

times the fault occurs.

C

OMFORT

N

ET

™ S

YSTEM

O

VERVIEW

The ComfortNet system is a system that includes a

ComfortNet compatible air handler and air conditioner or heat

pump with a CTK0* thermostat. Any other system configura-

tions are considered invalid ComfortNet systems and must

be connected as a traditional (or non-communicating) sys-

tem (see the 24 V

OLT

T

HERMOSTAT

W

IRING

- N

ON

-C

OMMUNICATING

T

HERMOSTAT

C

ONNECTIONS

section for details).

A ComfortNet heating/air conditioning system differs from a

non-communicating/traditional system in the manner in which

the indoor unit, outdoor unit and thermostat interact with one

another. In a traditional system, the thermostat sends com-

mands to the indoor and outdoor units via analog 24 VAC

signals. It is a one-way communication path in that the in-

door and outdoor units typically do not return information to

the thermostat.

On the other hand, the indoor unit, outdoor unit, and thermo-

stat comprising a ComfortNet system “communicate” digitally

with one another. It is now a two-way communications path.

The thermostat still sends commands to the indoor and out-

door units. However, the thermostat may also request and

receive information from both the indoor and outdoor units.

This information may be displayed on the ComfortNet ther-

mostat. The indoor and outdoor units also interact with one

another. The outdoor unit may send commands to or re-

quest information from the indoor unit. This two-way digital

communications between the thermostat and subsystems (in-

door/outdoor unit) and between subsystems is the key to

unlocking the benefits and features of the ComfortNet sys-

tem.

Two-way digital communications is accomplished using only

two wires. The thermostat and subsystem controls are pow-

ered with 24 VAC Thus, a maximum of 4 wires between the

equipment and thermostat is all that is required to operate

the system.

A

IRFLOW

C

ONSIDERATION

Airflow demands are managed differently in a fully commu-

nicating system than they are in a non-communicating wired

system. The system operating mode (as determined by the

thermostat) determines which unit calculates the system air-

flow demand. If the indoor unit is responsible for determin-

ing the airflow demand, it calculates the demand and sends

it to the ECM motor. If the outdoor unit or thermostat is re-

sponsible for determining the demand, it calculates the de-

mand and transmits the demand along with a fan request to

the indoor unit. The indoor unit then sends the demand to

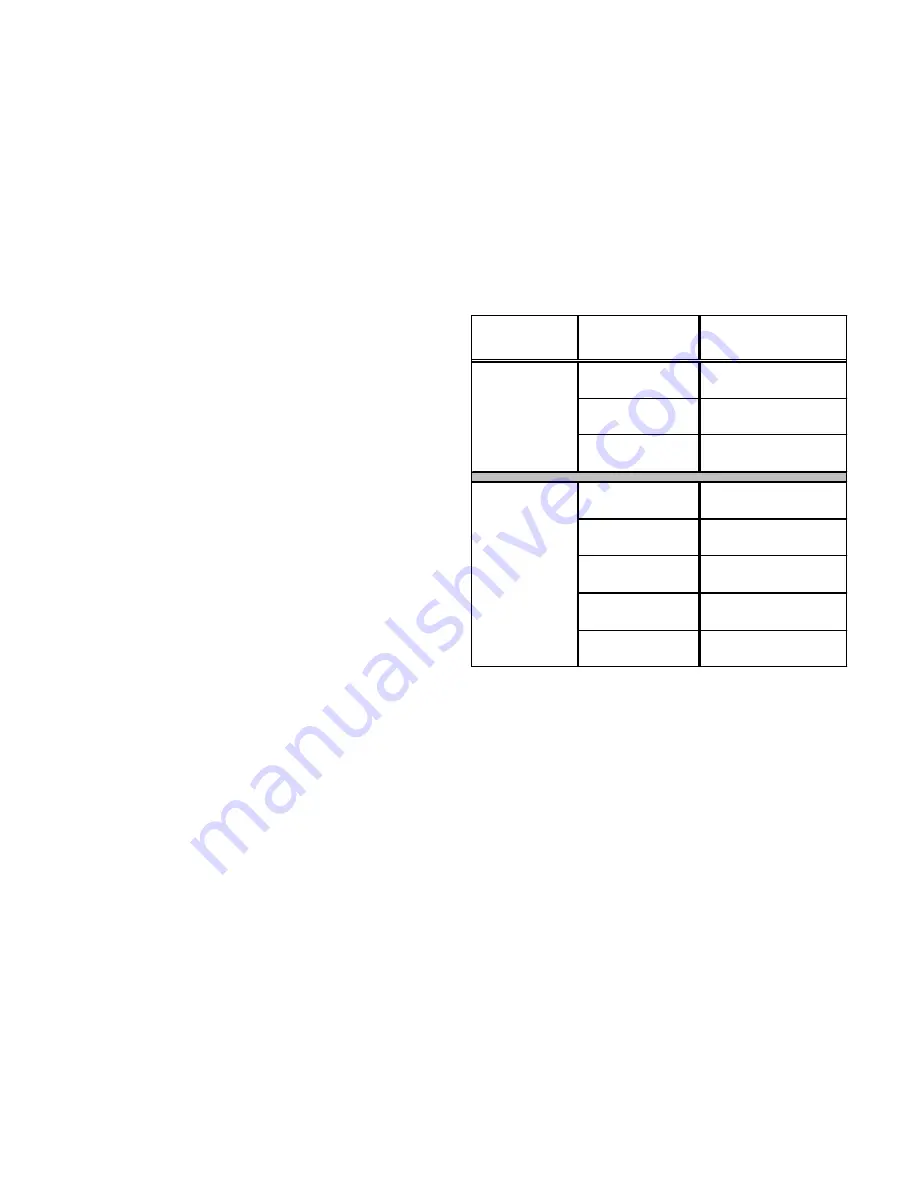

the ECM motor. The table below lists the various ComfortNet

systems, the operating mode, and airflow demand source.

System

System Operating

Mode

Airflow Demand Source

Cooling

Air Conditioner

Heating

Air Handler

Continuous Fan

Thermostat

Cooling

Heat Pump

Heat Pump Heating

Only

Heat Pump

HP + Electric Heat

Strips

> of Heat Pump or Air

Handler Demand

Electric Heat Strips

Only

Air Handler

Continuous Fan

Thermostat

Air Condi

Air Handler

Heat Pump + Air

Handler

For example, assume the system is a heat pump matched

with an air handler. With a call for low stage cooling, the

heat pump will calculate the system’s low stage cooling

airflow demand. The heat pump will then send a fan

request along with the low stage cooling airflow demand to

the air handler. Once received, the air handler will send the

low stage cooling airflow demand to the ECM motor. The

ECM motor then delivers the low stage cooling airflow.

See the applicable ComfortNet air conditioner or heat

pump installation manual for the airflow delivered during

cooling or heat pump heating.

In continuous fan mode, the CTK0* thermostat provides the

airflow demand. Depending on which CTK0* thermostat has

been installed three or four continuous fan speeds may be

available. If the thermostat provides three speeds (low,

medium, high) they correspond to 25%, 50% and 75%,

respectively, of the air handlers’ maximum airflow capability.

If the thermostat provides four continuous fan speeds then a

100% airflow option is added. During continuous fan operation,

the thermostat sends a fan request along with the continuous

fan demand to the air handler. The air handler, in turn, sends

the demand to the ECM motor. The ECM motor delivers the

requested continuous fan airflow.