SERVICING

63

Rev. 0

2. Next, remove wire connections from gas valve termi-

nals.

3. Using an ohmmeter, test across the gas valve coil ter-

minals M1 and C2.

Note: Make sure gas valve switch is in the "ON" position

when taking reading.

4. Should read approximately 100 Ohms for the White-

Rodgers 36E22 gas valve.

If not as above, replace the entire gas valve.

5. After check and/or replacement of gas valve, turn on

gas to furnace and check for leaks. If leaks are found,

repair and then reinstall burner compartment door.

6. Turn on electrical power and verify proper unit opera-

tion.

S-10 CHECKING MAIN BURNERS

The main burners are used to provide complete combus-

tion of various fuels in a limited space, and transfer this

heat of the burning process to the heat exchanger.

Proper ignition, combustion, and extinction are primarily due

to burner design, orifice sizing, gas pressure, primary and

secondary air, vent and proper seating of burners.

WARNING

Disconnect Electrical Power and Shut Off Gas Supply:

1. Remove burner compartment door to gain access to

manifold assembly.

2. Remove the entire manifold assembly from the front of

the heat exchanger assembly.

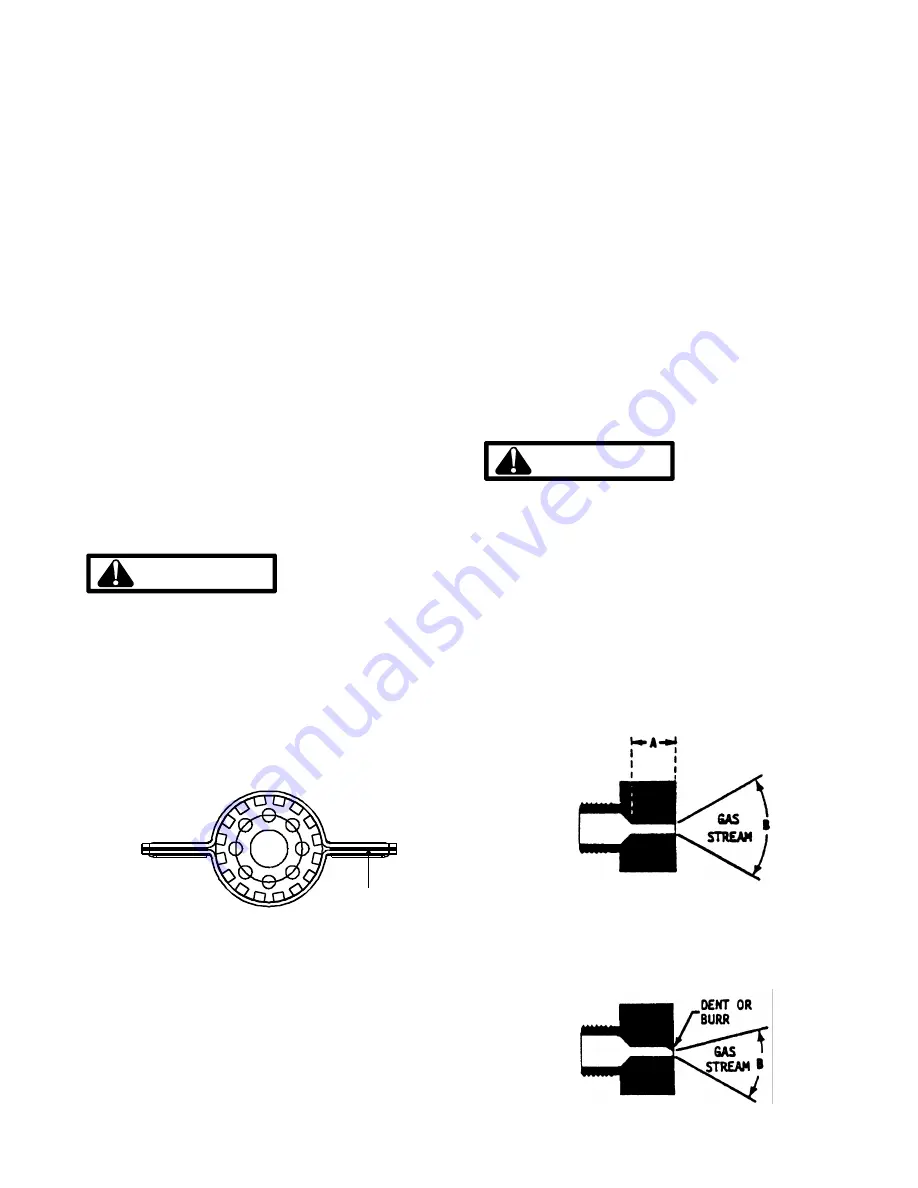

3. Check main burners for signs of rust, oversized and

undersized carryover ports or restrictions of foreign ma-

terial, etc. Refer to the following figure for the proper

dimension of the carryover ports.

SLOT TO BE

.023" - .027"

GUCA / GCCA Beckett Burner

4. After completing check, repair and/or replacement of

main burners, reinstall manifold assembly to front of

heat exchanger.

5. Turn on gas to furnace and check for leaks. If leaks are

found, repair and then reinstall burner compartment

door.

6. Turn on electrical power and verify poper unit opera-

tion.

S-11 CHECKING ORIFICES

A predetermined fixed gas orifice is used in all of these

furnaces. That is an orifice which has a fixed bore and po-

sition.

No resizing should be attempted until all factors are taken

into consideration such as inlet manifold gas pressure, align-

ment, positioning, specific gravity and BTU content of the

gas being consumed.

The only time resizing is required is when a reduction in

firing rate is required for an increase in altitude.

Orifices should be treated with care in order to prevent dam-

age. They should be removed and installed with a box-end

wrench in order to prevent distortion. In no instance should

an orifice be peened over and redrilled. This will change

the angle or deflection of the vacuum effect or entraining of

primary air, which will make it difficult to adjust the flame

properly. This same problem can occur if an orifice spud of

a different length is substituted.

WARNING

Disconnect Electrical Power and Shut Off Gas Supply:

1. Remove top access door to gain access to the mani-

fold assembly.

2. Remove manifold from burner bracket.

3. Check orifice visually for distortion and/or burrs.

4. Check orifice size with orifice sizing drills.

Note: It may be necessary to remove orifices from mani-

fold to view more clearly.

5. If resizing is required, a new orifice of the same physi-

cal size and angle with proper drill size opening should

be installed.

The length of Dimension "A" determines included angle of

Spray "B".

A dent of burr will cause severe deflection of gas stream.