7

(c) Where practical, close all building doors, windows, and

all doors between the space where the appliances

remain connected to the common venting system are

located and other spaces of the building. Turn on all gas

appliances not connected to the common venting sys-

tem and operate on high speed all exhaust fans (range

hoods and bathroom), except summer exhaust fans.

Close fireplace dampers.

(d) Following the lighting instructions, place the furnace

being inspected in operation. Adjust thermostat so

appliance will operate continuously.

(e) Test for spillage at the draft hood relief opening after 5

minutes of main burner operation. Use the flame of a

match or candle, or smoke from a cigarette, cigar, or

pipe.

(f) After it has been determined that each appliance re-

maining connected to the common venting system

properly vents when tested as outlined above, return

doors, windows, exhaust fans, fireplace dampers and

any other gas-burning appliance to their previous con-

ditions of use.

(g) If improper venting is observed during any of the above

tests, the common venting system must be corrected in

accordance with the latest edition of the National Fuel

Gas Code NFPA 54/ANSI Z223.1.

When resizing any portion of the common venting system,

use the appropriate table in Appendix G in the latest edition

of the National Fuel Gas Code NFPA 54/ANSI Z223.1.

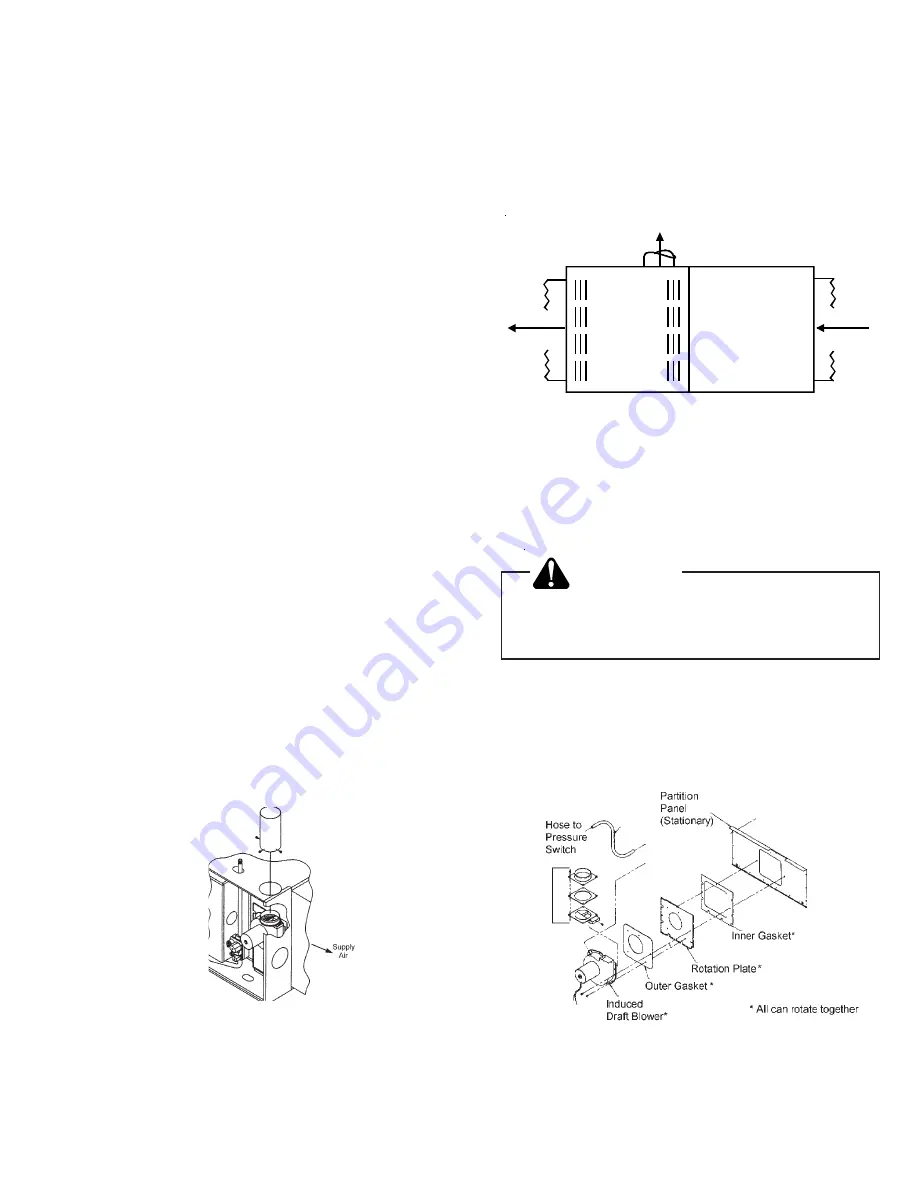

Upflow or Horizontal units

are shipped with the induced

draft blower discharging from the top of the furnace. (“Top”

is as viewed for an upflow installation.) The induced draft

blower can be rotated 90 degrees counterclockwise for

Category I venting, with the airflow horizontal left to right

(Figure 6). For horizontal installations, a four inch single

wall pipe can be used to extend the induced draft blower

outlet 1/2” beyond the furnace cabinet. Vent the furnace in

accordance with the National Fuel Gas Code NFPA 54/

ANSI Z223.1 - latest edition. In Canada, vent the furnace

in accordance with the National Standard of Canada, CAN/

CSA B149.1 and CAN/CSA B149.2 - latest editions and

amendments.

Figure 6

Upflow Rotated Induced Draft Blower

Counterflow units

are shipped with the induced draft

blower discharging from the top of the furnace. (“Top” as

viewed for a counterflow installation.) The induced draft

blower can be rotated 90 degrees counterclockwise for

Category I venting, with the airflow horizontal right to left

(Figure 7). For horizontal installations, a three inch B-vent

pipe can be used to extend the induced draft blower outlet

1/2” beyond the furnace cabinet. Vent the furnace in

accordance with the National Fuel Gas Code NFPA 54/

ANSI Z223.1 - latest edition. In Canada, vent the furnace in

accordance with the National Standard of Canada, CAN/

CSA B149.1 AND CAN/CSA B149.2 - latest editions and

amendments.

Supply

Air

Return

Air

Vent

Figure 7

Counterflow Rotated Induced Draft Blower

To rotate the induced draft blower counterclockwise pro-

ceed as follows:

1. Disconnect electrical power from furnace.

WARNING

To prevent death or personal injury due to

electrical shock, disconnect electrical

power.

2. Remove the round cutout from the side of the furnace.

Note:

The assembly, starting from the outside, is in-

duced draft blower, outer gasket, rotation plate, inner

gasket, partition panel (See Figure 8).

Figure 8

Blower Assembly