10

Additional Canadian Venting

Requirements

In Canada venting shall conform to the requirements

of the current CANI-B149 Installation Codes.

Use only C.S.A. Listed 2 inch or 3 inch nominal diam-

eter PVC or ABS pipe and fittings throughout.

The Minimum vent consists of 3 feet of straight pipe

with 2 elbows (9 equivalent feet).

A single wall vent shall not be run vertically through

the roof. The vent may be run through an existing

unused chimney as described in the previous venting

section provided the space between the vent pipe and

the chimney is insulated and closed with a weather

tight, corrosion resistant flashing.

Cut all vent pipe at right angles. Remove inside and

outside burr at each cut. Use cleaner to clean pipe

and fitting socket. Use CSA listed cement to fasten

pipe and fittings.

Follow manufacturers cleaning and cementing instruc-

tions carefully to avoid leakage.

NOTE:

ALL PIPING EXPOSED OUTDOORS OR IN

UNHEATED AREAS MUST BE INSULATED WITH

1/2 inch THICK CLOSED CELL FOAM INSULATION

SUCH AS ARMAFLEX OR INSULTUBE.

The vent terminal shall

not

be located:

1. Less than 12 inches above the finished grade line.

2. Less than 36 inches from any building opening or

any gas service regulator. (For gas service regula-

tors in the Province of Ontario, 72 inches.)

3. Less than 72 inches from the combustion air inlet of

another appliance.

4. Directly above a gas utility meter or service regula-

tor.

5. Over a walkway unless 84 inches above grade.

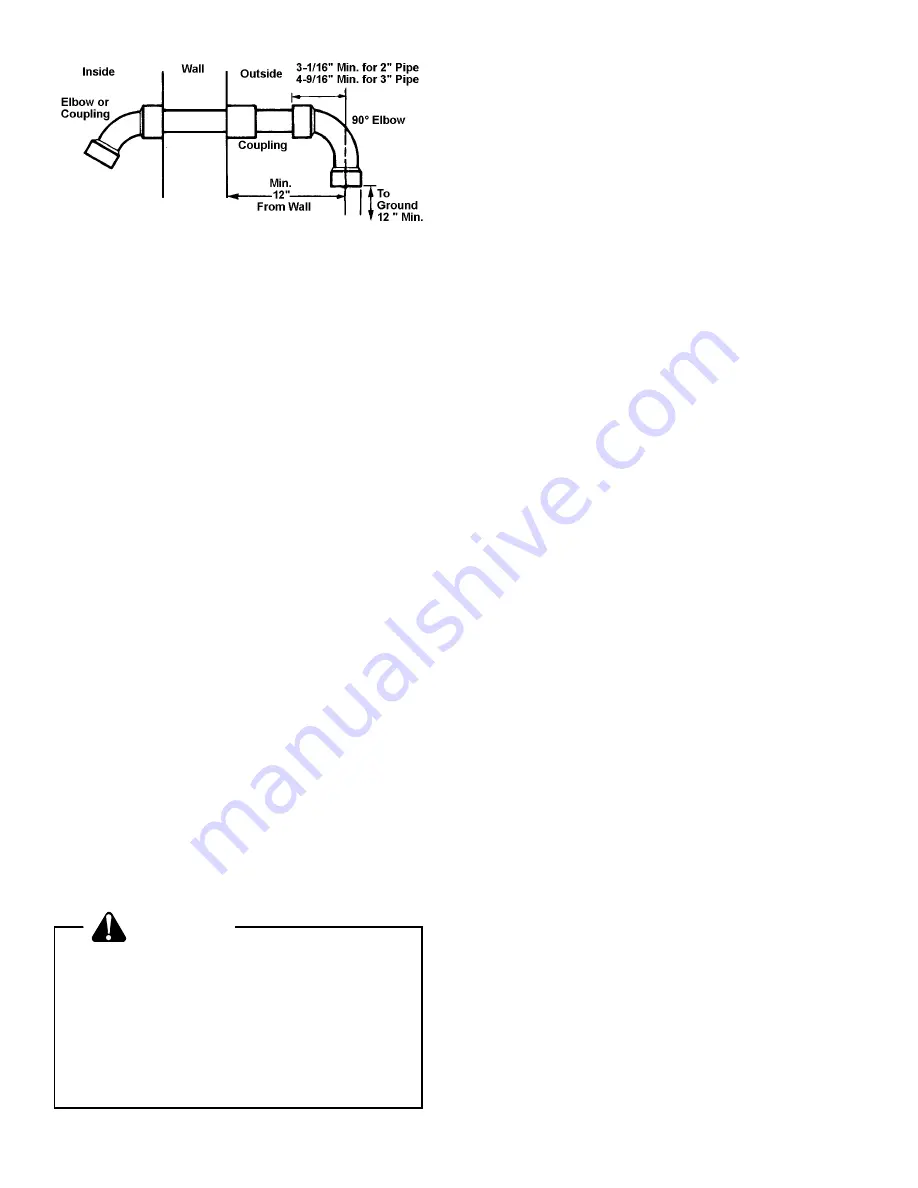

Figure 5

Horizontal Vent Termination

In a basement installation,

the vent pipe may be run

between the joist spaces. If the vent must go below the

joists, then the pipe must run up into the last joist space

to go through the header. Two 45° elbows should be

used rather than 90s. The horizontal run must not have

any sag that can hold condensate and should pitch up at

least 1/4 inch per foot so that condensate will run back

to the unit to drain. Support the horizontal run at least

every three feet. Allow for some expansion and con-

traction from temperature fluctuations. The normal di-

rection changes usually account for this, but if you have

a long run followed by a short offset of less than 40

inches such as going up into the last joist space, the

pipe should be tightly clamped to prevent flex loading

on the fittings. Seal around the pipe on the outside wall

with silicone caulking material.

If the vent is to be run vertically through the roof,

it must

extend at least 12 inches above the roof line and shall

be at least 12 inches from any vertical wall. It must

terminate at least three feet above any forced air inlet

located within 10 feet, and at least 12 inches from any

door, window, or gravity air inlet into any building. If

heavy snow is expected to remain on the roof, the

clearances to vertical walls and the roof may need to be

increased. The vent must be made tight where it pen-

etrates the roof with a proper flashing such as used with

a plastic plumbing vent. The vent may be run through

an existing

unused

chimney: however, the pipe must

be used all the way through to at least 12 inches above

the top of the existing chimney. The space between the

vent pipe and the chimney must be closed with a weather

tight, corrosion resistant flashing.

Never vent with an

existing appliance or vent used by a solid fuel appliance.

WARNING

Upon completion of the furnace installa-

tion, carefully inspect the entire flue sys-

tem both inside and outside the furnace

to assure it is properly sealed. Leaks in

the flue system can result in serious per-

sonal injury or death due to exposure to

flue products, including carbon monox-

ide.