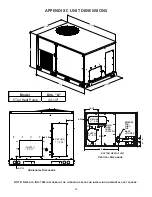

9

4-1/2"

47-9/16"

7-1/2"

4-1/16 DIA.

POWER THRU

THE CURB

RETURN

19-3/8

31-3/8

LOW VOLTAGE

ENTRANCE

HIGH VOLTAGE ENTRANCE

(REMOVE PLUG)

electrical entrance and thru curb

(bottom view of unit)

Low Voltage Control Wiring

1. A 24V thermostat must be installed for unit operation.

2. Locate thermostat or remote sensor in the

conditioned space where it will sense average

temperature. Do not locate the device where it may

be directly exposed to supply air, sunlight or other

sources of heat. Follow installation instructions

packaged with the thermostat.

3. Use #18 AWG wire for 24V control wiring runs not

exceeding 75 feet. Use #16 AWG wire for 24V

control wiring runs not exceeding 125 feet. Use #14

AWG wire for 24V control wiring runs not exceeding

200 feet. Low voltage wiring may be National

Electrical Code (NEC) Class 2 where permitted by

local codes.

4. Route thermostat wires from sub-base terminals

to the unit. Control wiring should enter through the

condenser panel opening or through curb indicated

in “Electrical Entrance” figure. Connect thermostat

and any accessory wiring to low voltage terminal

block TB1 in the main control box.

NOTE: Field-supplied conduit may need to be

installed depending on unit/curb configuration.

Use #18 AWG solid conductor wire whenever

connecting thermostat wires to terminals on

sub-base. DO NOT use larger than #18 AWG wire.

A transition to #18 AWG wire may be required

before entering thermostat sub-base.

NOTE: Refer to unit wiring diagrams for

thermostat or remote sensor connections.

CIRCULATING AIR AND FILTERS

Ductwork

The supply duct from the unit through a wall may be

installed without clearance. However, minimum unit

clearances must be maintained (see “Clearances” section).

The supply duct should be provided with an access panel

large enough to inspect the air chamber downstream of

the heat exchanger. A cover should be tightly attached to

prevent air leaks.

Ductwork dimensions are shown in the roof curb

installation manual.

If desired, supply and return duct connections to the unit

may be made with flexible connections to reduce possible

unit operating sound transmission.

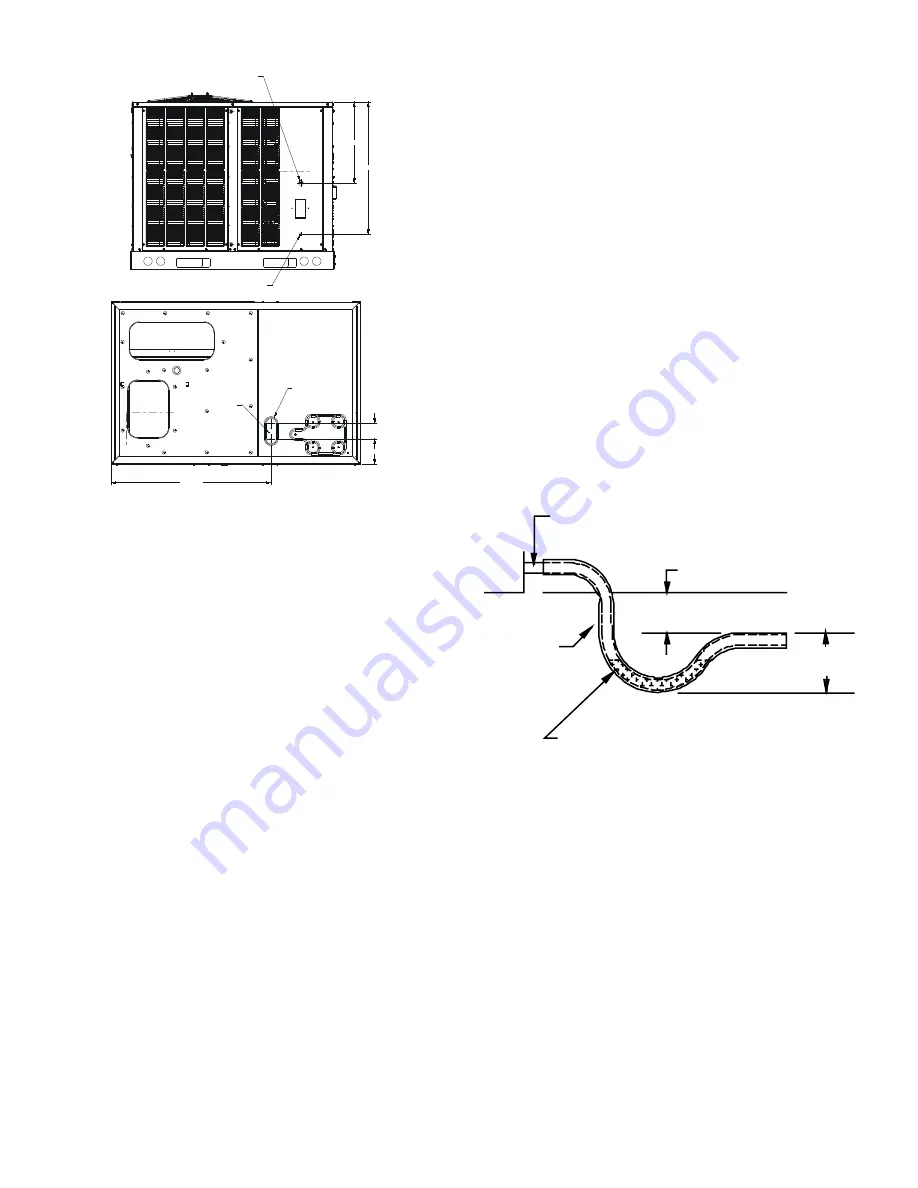

CONDENSATE DRAIN CONNECTION

Condensate Drain Connection

A 3/4” female NPT drain connection is supplied on the

end of the unit and bottom of the drain pan for condensate

piping. An external trap must be installed for proper

condensate drainage. Hand tighten drain fitting to the drain

connection.

DRAIN

CONNECTION

UNIT

2" MINIMUM

FLEXIBLE

TUBING-HOSE

OR PIPE

3" MINIMUM

A POSITIVE LIQUID

SEAL IS REQUIRED

drain connection

Install condensate drain trap as shown. Use 3/4” drain line

and fittings or larger. Do not operate without trap.

Horizontal Drain

Drainage of condensate directly onto the roof may be

acceptable; refer to local code. It is recommended that a

small drip pad of either stone, mortar, wood or metal be

provided to prevent any possible damage to the roof.

Vertical Drain

To use the bottom drain connection, remove the drain plug

from the bottom connection and install it in the horizontal

connection.

Cleaning

Due to the fact that drain pans in any air conditioning

unit will have some moisture in them, algae and fungus

will grow due to airborne bacteria and spores. Periodic

cleaning is necessary to prevent this build-up from plugging

the drain.

Summary of Contents for M Series

Page 15: ...15 Wiring Example Electric Heat Wiring Example ...

Page 21: ...21 ...

Page 22: ...22 ...